A kind of glass fiber reinforced wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite material and glass fiber, which is applied in the direction of coating, etc., can solve the problems of poor bonding between glass fiber and wood-plastic interface, low recovery rate of waste wood-plastic products, single type of waste plastic, etc., to achieve high process pressure, The effect of high strength and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

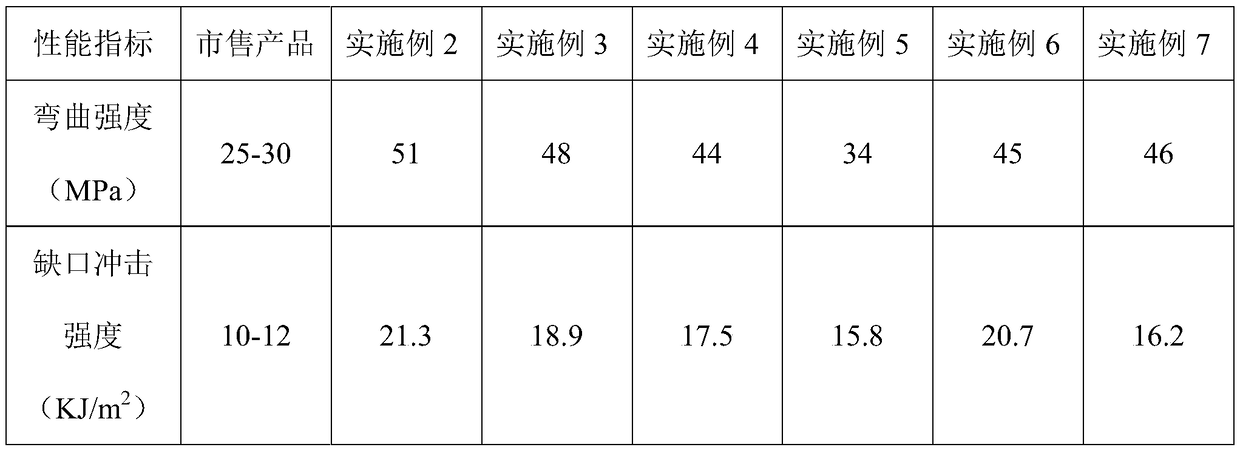

Examples

Embodiment 1

[0026] The glass fiber reinforced wood-plastic composite material provided in Example 1 is mainly composed of glass fibers, waste plastics, plant fibers, and regulators, and its mass ratio is (5-30): (30-60): (0-15 ): (20-40), the glass fiber adopts plastic-coated glass fiber, and the regulator is PP, PE, PVC, PP-g-MAH, PE-g-MAH, EVA-g-MAH one or more of them.

[0027] The plant fiber is one or more of wood powder, bamboo powder, straw powder, bagasse powder, and rice husk powder, and its mesh number is 40-80 mesh, or it has an aspect ratio of 20-100 of hemp fiber.

[0028] The glass fiber reinforced wood-plastic composite material provided in Example 1 above can be made by the method provided in the following examples.

Embodiment 2

[0030] S1 Glass fiber impregnation process: Add 40 parts of PP, 45 parts of PP wax, and 15 parts of PP-g-MAH into the dipping tank to melt and mix well. The temperature of the dipping tank is controlled at 200-210 °C. The glass fiber bundles were impregnated in a dipping tank, and then rolled, cooled, and cut to obtain plastic-coated glass fibers with a length of 10 mm. Said parts are parts by weight, the same below.

[0031] S2 Mixing powder making process: Add 30 parts of PP, 10 parts of PP-g-MAH, 30 parts of crushed waste plastic mixture, and 15 parts of plant fiber into the internal mixer to mix evenly and granulate. The material is crushed into 10-30 mesh powder with a pulverizer, and the temperature of the internal mixer is controlled between 140-190°C.

[0032] S3 hot press molding process: take 70 parts of powder in S2, 30 parts of plastic-coated glass fiber in S1, mix evenly and lay them in the mold, and first cold press and compact. Then put it into a hot press for...

Embodiment 3

[0034] S1 Glass fiber impregnation process: Add 50 parts of PP, 38 parts of high melting index PP, and 12 parts of PP-g-MAH into the dipping tank to melt and mix well. The temperature of the dipping tank is controlled at 200-210 °C. The glass fiber bundles were impregnated in a dipping tank, and then rolled, cooled, and cut to obtain plastic-coated glass fibers with a length of 20 mm.

[0035]S2 Mixing powder making process: Add 20 parts of PE, 10 parts of PE-g-MAH, 45 parts of crushed waste plastic mixture, and 10 parts of plant fiber into the internal mixer to mix evenly and granulate. Pulverize into 30-50 purpose powder with pulverizer, internal mixer temperature is controlled between 140-190 ℃.

[0036] S3 hot press molding process: Take 80 parts of powder in S2 and 20 parts of plastic-coated glass fiber in S1, mix them evenly and spread them in the mold, and first cold press and compact them. Then put it into a hot press for preheating at 135-180°C, pressurize and exhaus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com