Bamboo bunch heat-moisture treatment method

A wet heat treatment, bamboo bunching technology, applied in reed/straw treatment, wood processing utensils, manufacturing tools, etc., can solve the problems of limited improvement in dimensional stability, mildew resistance and other properties of reconstituted bamboo, low steam treatment temperature, and high risk , to reduce product chromatic aberration defects, improve uniformity, uniform color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

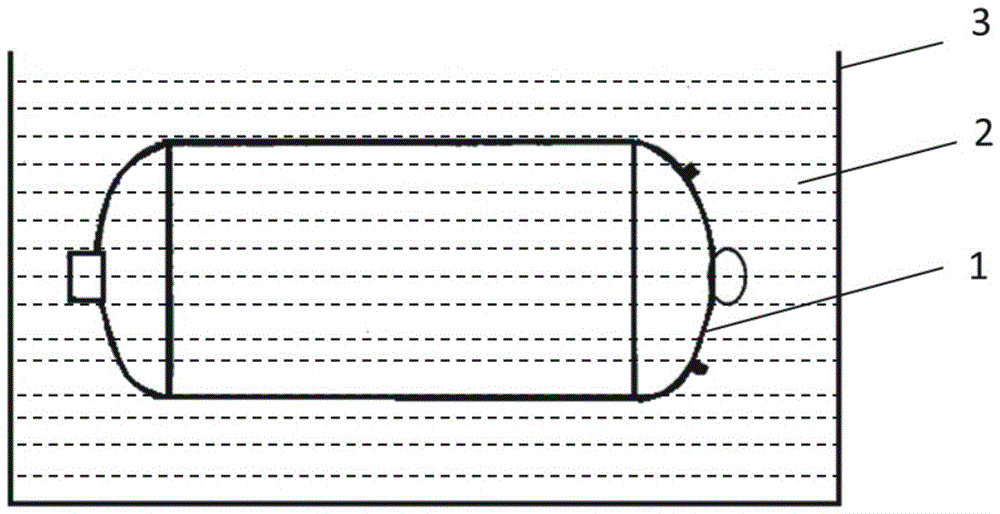

[0014] The equipment used in the bamboo bundle heat treatment equipment of the present invention comprises a pressure tank (1) and an oil pool (3), comprising the following steps: (1) preparation of bamboo bundles, (2) heat treatment of bamboo bundles, (3) drying of bamboo bundles,

[0015] (1) Bamboo bundle preparation:

[0016] After the fresh bamboo is processed into 5mm thick bamboo strips, it is decomposed into bamboo bundles with a diameter of 1.5mm fiber bundles by using a decomposer;

[0017] (2) Bamboo bundle heat treatment

[0018] Put the bamboo bundles into the pressure tank (1) in parallel or crosswise along the direction of the grain, and after closing the door of the pressure tank, let in saturated steam to rapidly raise the temperature of the medium in the pressure tank to 100-120°C. When the pressure reaches 0.10-0.12MPa, put the bamboo bundles together with the pressure tank (1) into the oil pool (3) for heat treatment, in this process, ensure that the hot o...

Embodiment 2

[0022] The equipment used in the bamboo bundle heat treatment equipment of the present invention comprises a pressure tank (1) and an oil pool (3), comprising the following steps: (1) preparation of bamboo bundles, (2) heat treatment of bamboo bundles, (3) drying of bamboo bundles,

[0023] (1) Bamboo bundle preparation:

[0024] After the fresh bamboo is processed into 3mm thick bamboo strips, it is decomposed into bamboo bundles with a diameter of 3mm fiber bundles by using a decomposer;

[0025] (2) Bamboo bundle heat treatment

[0026] Put the bamboo bundles into the pressure tank (1) in parallel or crosswise along the grain direction, close the pressure tank door; put the bamboo bundles together with the pressure tank (1) into the oil pool (3) for Heat treatment, in this process, ensure that the hot oil (2) submerges the entire tank body of the pressure tank. The temperature of the hot oil (2) in the oil pool is 200°C, and the treatment time is 5 hours. After that, the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com