Abrasive concentration control system for front mixed abrasive water jet equipment

An abrasive water jet and pre-mixing technology, which is applied to abrasive feeding devices, abrasives, metal processing equipment, etc., can solve the problems that the abrasive concentration cannot be kept constant, the cutting efficiency is reduced, and the cutting quality is reduced, etc., to improve the utilization of abrasives. rate and cutting efficiency, ensuring cutting quality, and the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below through embodiment form, content of the present invention is described in further detail, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical idea of the present invention, all according to this field Various modifications, substitutions and changes made by ordinary technical knowledge and conventional means are included within the scope of protection of the present invention.

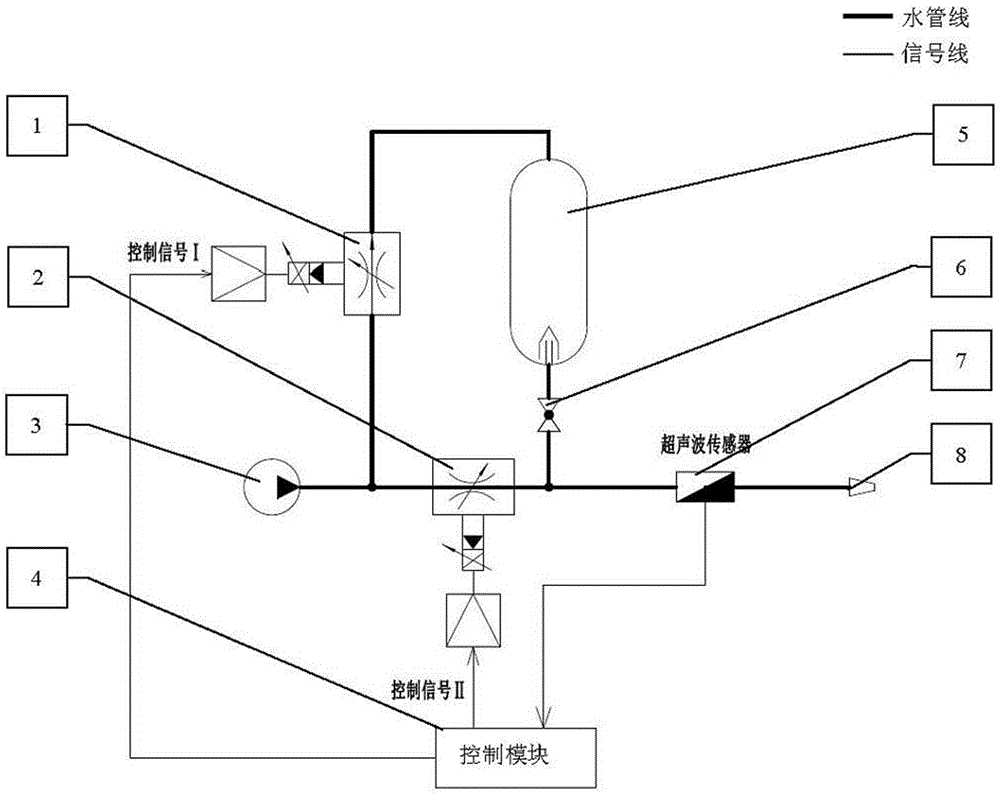

[0022] figure 1 It is a block diagram of the abrasive concentration control system in the present invention. The abrasive concentration control system used in the pre-mixing abrasive water jet equipment according to the present invention includes: bypass proportional flow valve 1, main path proportional flow valve 2, high pressure Water pump 3, control module 4, high pressure tank 5, ball valve 6, ultrasonic concentration detector 7, nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com