Automobile exhaust purification catalyst carrier

A technology for purifying catalysts and automobile exhaust, which is applied in catalyst carriers, physical/chemical process catalysts, catalyst activation/preparation, etc., can solve problems such as high cost, inability to achieve rational utilization of catalysts, waste of resources, etc., to ensure service life, improve The effect of exhaust gas evolution and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

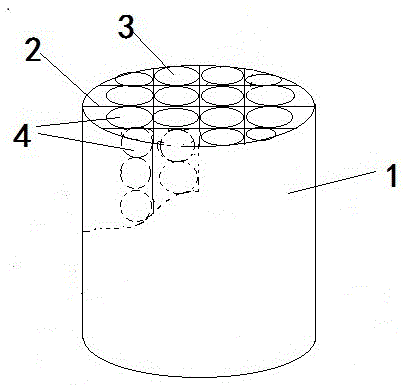

[0024] A catalyst carrier for automobile exhaust gas purification, the carrier includes a sleeve body, a grid installed inside the sleeve body and a porous composite ball fixedly arranged in the grid, an exhaust gas channel is left between the porous composite ball and the grid wall,

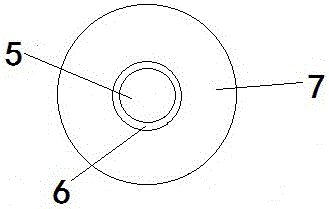

[0025] The porous composite ball includes a core ball, the core ball is a titanium alloy, the core ball is coated with a nickel-based alloy layer, and the nickel-based alloy layer is a porous composite layer,

[0026] The composition of each element of titanium alloy is: Mn6﹪, V3﹪, Zr2﹪, Al0.7﹪, In0.5﹪, Ca0.3﹪, N0.1﹪, Mg0.08﹪, Sb0.06﹪, C0. 04﹪, Ce0.01﹪, Cr0.01﹪, the balance is Ti,

[0027] The composition of each element of the nickel-based alloy is: Mn0.7﹪, V0.3﹪, Zr0.2﹪, In0.5﹪, Ag0.1﹪, Bi0.1﹪, Mg0.08﹪, Ce0.04﹪, Cr0.03﹪, Ba0.02﹪, Nd0.01﹪, the balance is Ni

[0028] The porous composite layer is composed of (mass) 100 parts of fluorite powder, 20 parts of activated carbon, 10 parts of aluminu...

Embodiment 2

[0030] A catalyst carrier for automobile exhaust gas purification, the carrier includes a sleeve body, a grid installed inside the sleeve body and a porous composite ball fixedly arranged in the grid, an exhaust gas channel is left between the porous composite ball and the grid wall,

[0031] The porous composite ball includes a core ball, the core ball is a titanium alloy, the core ball is coated with a nickel-based alloy layer, and the nickel-based alloy layer is a porous composite layer,

[0032] The composition of each element of titanium alloy is: Mn7﹪, V4﹪, Zr3﹪, Al0.8﹪, In0.6﹪, Ca0.4﹪, N0.2﹪, Mg0.09﹪, Sb0.07﹪, C0. 05﹪, Ce0.02﹪, Cr0.02﹪, the balance is Ti,

[0033] The composition of each element of the nickel-based alloy is: Mn0.8﹪, V0.4﹪, Zr0.3﹪, In0.6﹪, Ag0.2﹪, Bi0.2﹪, Mg0.09﹪, Ce0.05﹪, Cr0.04﹪, Ba0.03﹪, Nd0.02﹪, the balance is Ni

[0034] The porous composite layer is composed of (mass) 100 parts of fluorite powder, 30 parts of activated carbon, 20 parts of aluminu...

Embodiment 3

[0036] A catalyst carrier for automobile exhaust gas purification, the carrier includes a sleeve body, a grid installed inside the sleeve body and a porous composite ball fixedly arranged in the grid, an exhaust gas channel is left between the porous composite ball and the grid wall,

[0037] The porous composite ball includes a core ball, the core ball is a titanium alloy, the core ball is coated with a nickel-based alloy layer, and the nickel-based alloy layer is a porous composite layer,

[0038] The composition of each element of titanium alloy is: Mn6.5﹪, V3.5﹪, Zr2.5﹪, Al0.75﹪, In0.55﹪, Ca0.35﹪, N0.15﹪, Mg0.085﹪, Sb0 .065﹪, C0.045﹪, Ce0.015﹪, Cr0.015﹪, the balance is Ti,

[0039] The composition of each element of the nickel-based alloy is: Mn0.75﹪, V0.35﹪, Zr0.25﹪, In0.55﹪, Ag0.15﹪, Bi0.15﹪, Mg0.085﹪, Ce0.045﹪, Cr0.035﹪, Ba0.025﹪, Nd0.015﹪, the balance is Ni

[0040] The porous composite layer consists of (mass) 100 parts of fluorite powder, 25 parts of activated carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com