Clean flue gas bio-desulfurization and denitrification method and apparatus thereof

A biological desulfurization and flue gas technology, applied in the field of environmental biology, can solve the problems of difficult treatment, increase the difficulty and cost of wastewater treatment, and the inability to realize sulfur recovery, and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

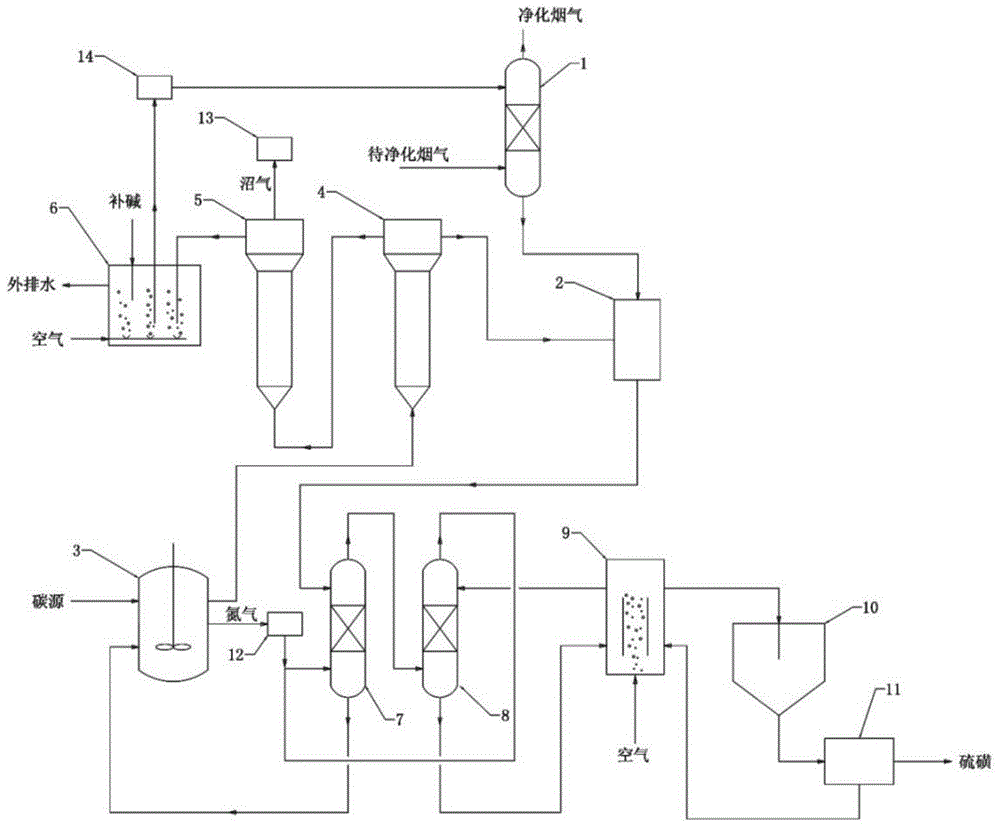

[0067] Embodiment 1 Clean flue gas biological desulfurization and denitrification process flow

[0068] Such as figure 1 As shown, the clean flue gas biological desulfurization and denitrification integrated process of the present invention is mainly composed of flue gas absorption, sulfide stripping / hydrogen sulfide absorption, facultative denitrification, anaerobic sulfate reduction, anaerobic methanogenesis, micro-oxygen sulfur oxidation It is composed of elemental sulfur production, sulfur recovery and aerobic aeration tank. The specific process is as follows:

[0069] 1) Take 0.2~0.5M NaHCO 3 As the absorption liquid, the sulfur oxides and nitrogen oxides in the flue gas to be treated after dedusting and cooling are absorbed in the absorption tower 1, and the pH value of the absorption rich liquid is reduced to 4.0-5.0 by controlling the gas-liquid ratio.

[0070] 2) Absorb the rich liquid and anaerobic sulfate reduction reactor 4 backflow and mix in the mixing tank 2 ...

Embodiment 2

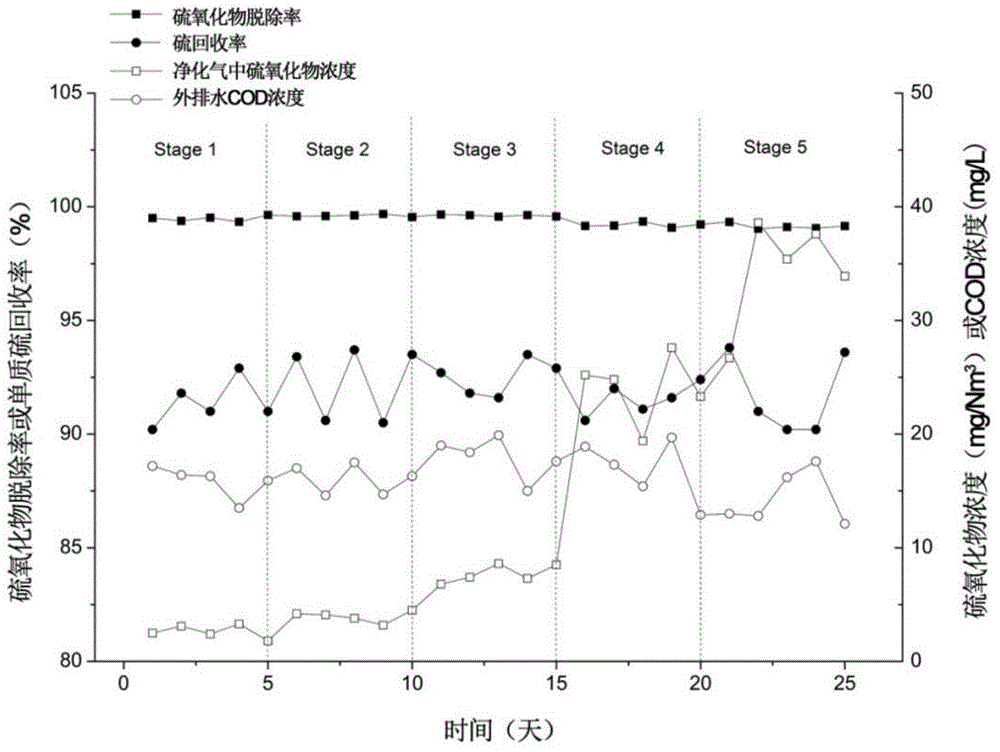

[0082] Embodiment 2 The treatment effect of the present invention on simulated flue gas with different sulfur oxide concentrations

[0083] Simulated flue gas: SO x Concentration (as SO 2 Total) is 500, 1000, 2000, 3000, 4000mg / Nm 3 (Stage1~5).

[0084] Gas flow rate: 1.0Nm3 / h.

[0085] Absorption of poor solution: with 0.2M NaHCO 3 The pH of the solution was adjusted to 7.5.

[0086] Hydrogen sulfide absorbent: Na 2 CO 3 solution.

[0087] Supplementary carbon source: The control system automatically adds ethanol according to the pH difference between the absorbed poor solution and the rich solution.

[0088] What kind of strain is the biological sulfur oxidation reactor? The denitrifying bacteria were taken from the denitrification sludge of the municipal sewage treatment plant and inoculated in the facultative denitrification reactor; the anaerobic sludge of the municipal sewage treatment plant was inoculated in the anaerobic sulfate reduction reactor and the meth...

Embodiment 3

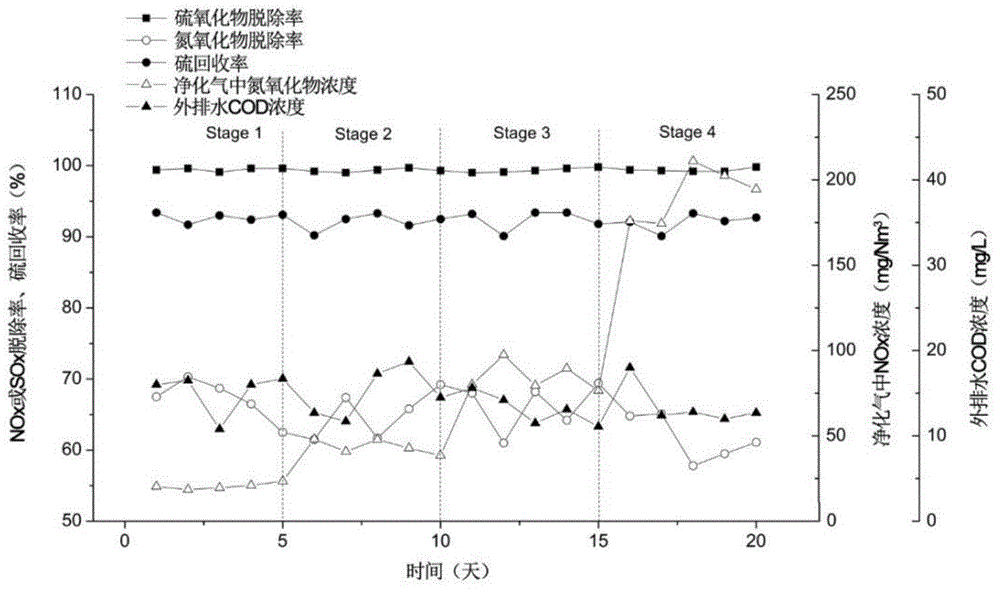

[0093] Example 3 The treatment effect of the present invention on simulated flue gas with different ratios of sulfur oxides and nitrogen oxides

[0094] Simulated flue gas: SO x Concentration (as SO 2 Total) 2000mg / Nm 3 , NO x Concentration (as NO 2 Total) 50, 100, 200, 400mg / Nm 3 (Stage1~4).

[0095] Other processing conditions are identical with embodiment 2.

[0096] The experimental results are attached image 3 shown. Simulated flue gas treated SO x Concentration down to 3 , SO x Removal rate>99%. due to NO x Including insoluble NO in water, NO x The removal rate is as low as 50-70%. After flue gas is treated with biological desulfurization and denitrification, NO x Concentration down to 200mg / Nm 3 Hereinafter, the removal rate of nitrate nitrogen generated after nitrogen oxides are absorbed is 100%. Indexes such as sulfur recovery rate, sulfur purity, and effluent COD are similar to those in Example 2, being >90%, >98%, and 3 .

[0097] This example show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com