Windowing terminal point determining method for solar energy cell laser back electrode window

一种终点判断、背电极的技术,应用在太阳能电池领域,能够解决激光背电极窗口开窗工艺难直接应用于大规模电池生产、激光背电极窗口开窗工艺工艺难度、无法达到刻蚀绝缘钝化层等问题,达到开窗终点判断方法简单易行、缩短检测时间、成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The method for judging the end point of window opening of the solar cell laser back electrode window in the embodiment of the present invention includes the following steps:

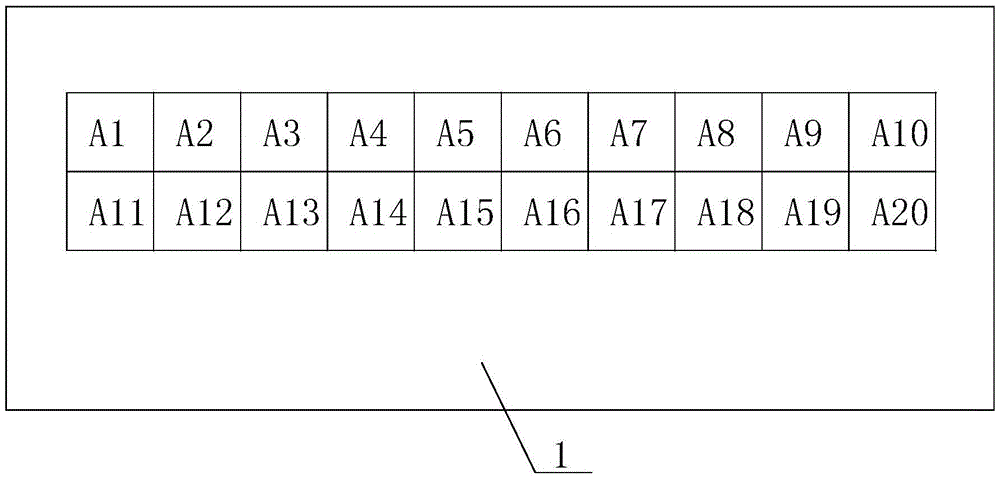

[0028] Step 1. Select a cell from the same batch of cells as a sample sample. A back passivation layer with a uniform thickness is deposited on the back of the cell sample. In this example, the back passivation layer is a silicon nitride layer.

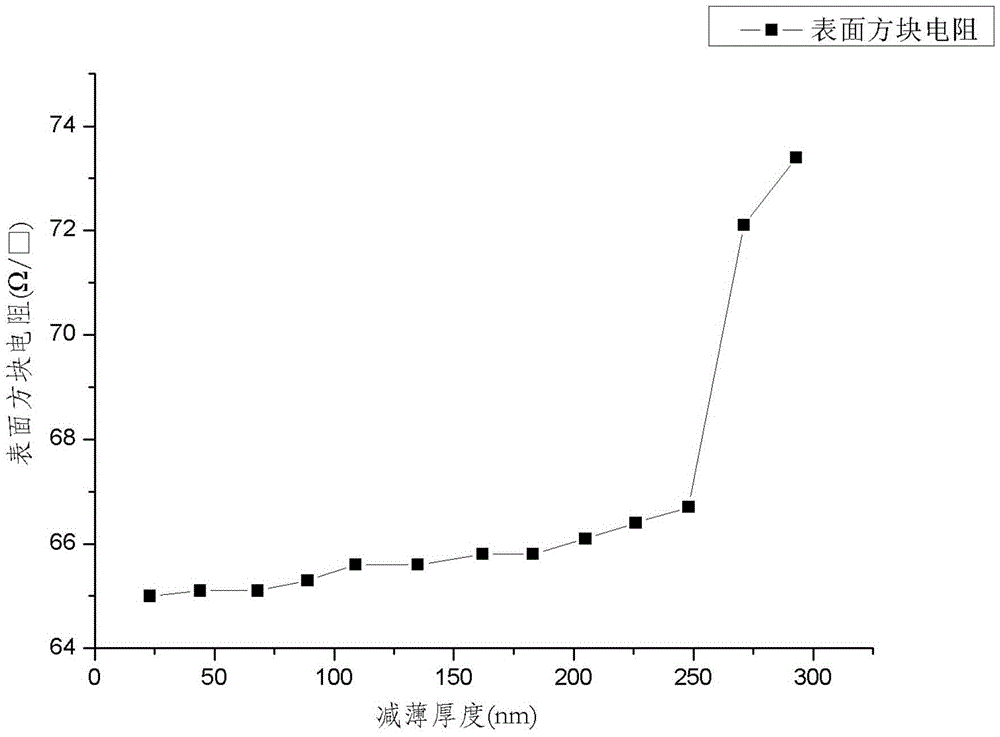

[0029] Step 2. In an oxygen-free environment, use a pulsed laser with the same wavelength and pulse frequency to etch the back of the cell sample 20 times. The area of the first etching is 20*100mm 2 , the second etching area is 19*100mm 2 , and so on, the area of the 10th etching is 100mm 2 , the area of the second etching is within the area of the first etching, the area of the third etching is within the are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com