Semiconductor apparatus manufacturing method and manufacturing apparatus

A manufacturing method and semiconductor technology, which are used in the manufacture of semiconductor devices and the field of manufacturing devices, can solve problems such as poor adhesion, inability to ensure adhesion strength, immersion, etc., and achieve the effect of preventing outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

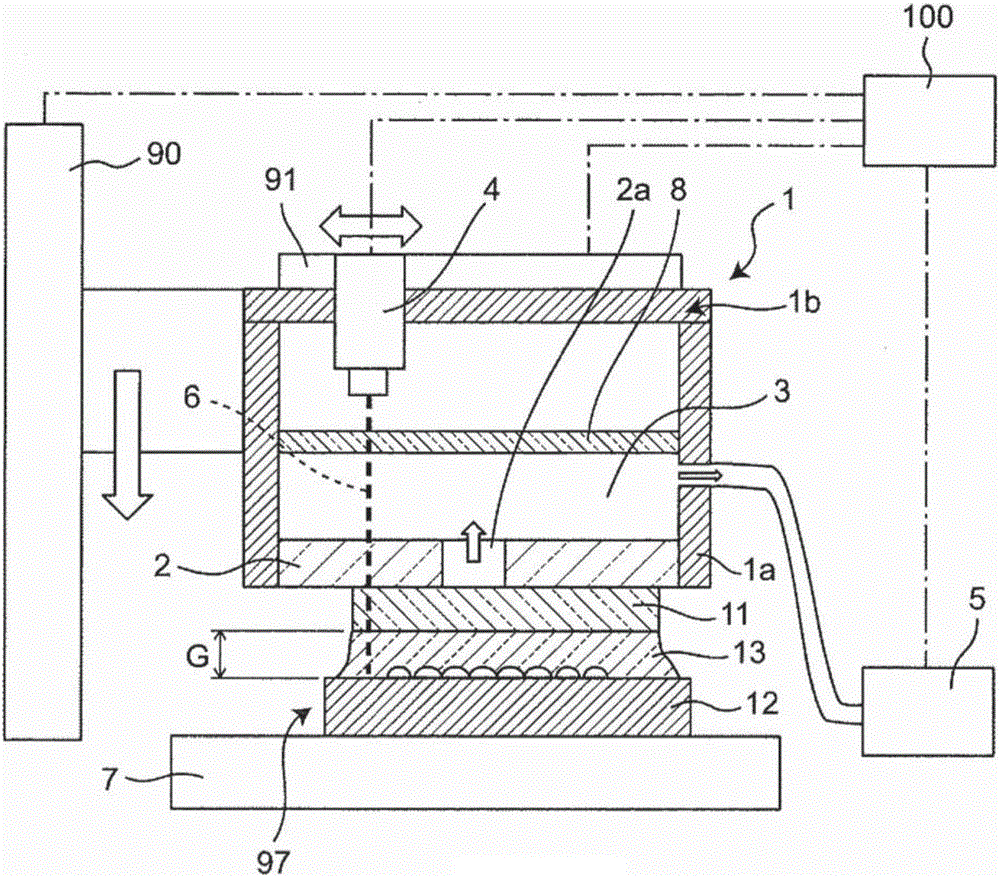

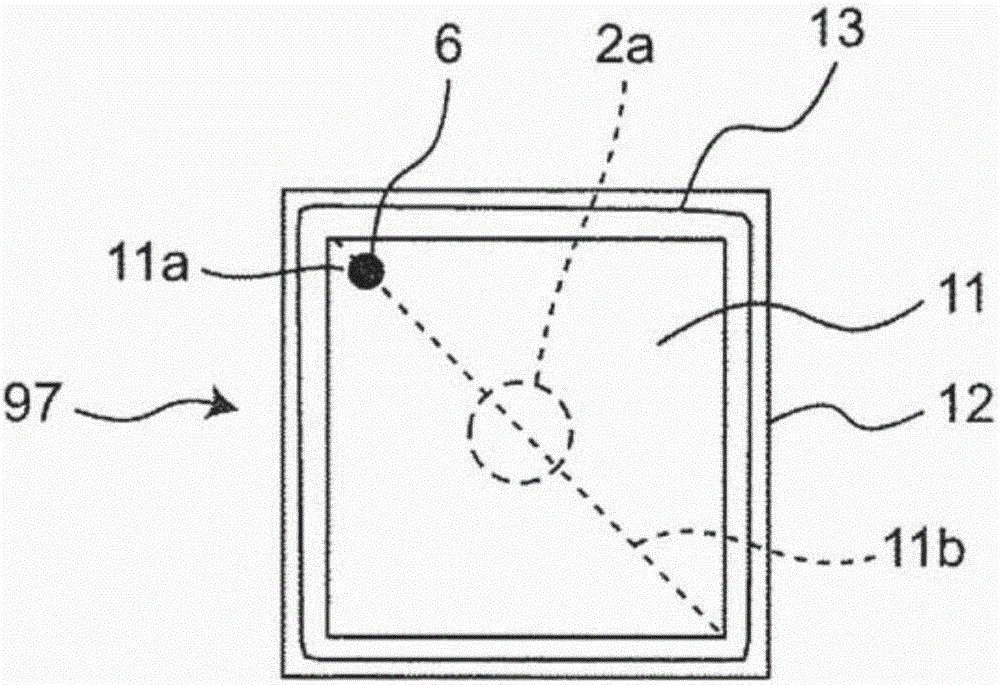

[0094] Figure 1A as well as Figure 1B It is a schematic sectional view showing the structure of the manufacturing apparatus of the semiconductor device 97 in the first embodiment of the present invention, and a plan view of the semiconductor device 97 .

[0095] Figure 1A The semiconductor device manufacturing apparatus according to the first embodiment shown includes: a stage 7, a mounting head 1 functioning as an example of a suction tool, a mounting head drive mechanism 90, an example of a distance measuring device, and an adhesion state inspection device. An example of a device is the non-contact distance measurement mechanism 4 , the measurement mechanism drive mechanism 91 , the position information acquisition device 92 , and the control device 100 .

[0096] The stage 7 fixes the substrate 12 on which the bonding member 13 is formed.

[0097] The mounting head 1 includes a rectangular parallelepiped box-shaped main body 1 b , a transparent suction plate 2 , a tra...

no. 2 Embodiment approach

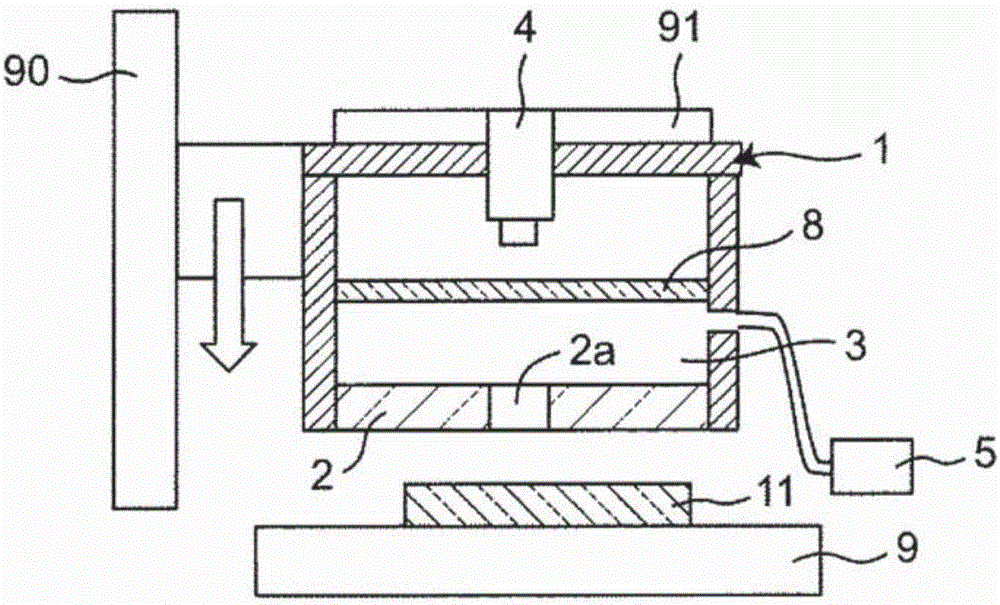

[0120] The second embodiment of the present invention differs from the first embodiment in that a mounting member 31 smaller than the mounting member 11 of the first embodiment is used; an example of a distance measuring device and an example of an adhesive state inspection device The non-contact distance measuring part 24a of the functioning non-contact distance measuring mechanism 24 is fixed, and the mirror moves; and there are two measuring positions of the laser light 26 in the inspection process.

[0121] Figure 4A ~ Figure 4F These are a schematic cross-sectional view and a plan view of the semiconductor device sequentially showing the method for manufacturing the semiconductor device in the second embodiment of the present invention.

[0122] right Figure 4A and Figure 4B The structure of the semiconductor device manufacturing apparatus of the second embodiment shown will be described. The semiconductor device manufacturing apparatus of the second embodiment incl...

no. 3 Embodiment approach

[0140] The third embodiment of the present invention has the same configuration as the semiconductor device manufacturing apparatus in the first embodiment, but differs from the first and second embodiments in that a mounting member 41 with a large warp is used, And there are four measurement locations of the laser beam 6 in the inspection process. In addition, in 3rd Embodiment, the same code|symbol is attached|subjected to the same structure as 1st Embodiment, and description is abbreviate|omitted.

[0141] The inspection process of the semiconductor device in the third embodiment will be described. Figure 5A ~ Figure 5C It is a schematic cross-sectional view and a plan view of the semiconductor device sequentially showing the manufacturing method of the semiconductor device in the third embodiment of the present invention. The steps of the following manufacturing method are also all performed under the control of the control device 100 .

[0142] First, under the control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com