Rare earth permanent magnet and its preparation method

A rare earth permanent magnet and magnetic powder technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve problems such as difficult to control, uncontrollable, and uneven distribution of magnetic properties of magnets, and the method is simple to achieve and avoid oxidation deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a kind of preparation method of rare earth permanent magnet, and it comprises the following steps:

[0030] S1, providing a magnetic powder, and making the magnetic powder into a preformed blank;

[0031] S2, heating the preformed blank under vacuum or protective atmosphere conditions, and then rolling the preformed blank by at least one roll to deform the preformed blank to obtain a rare earth permanent magnet.

[0032] In step S1, the source of the magnetic powder is not limited, it can be quenched magnetic powder, HDDR magnetic powder (HDDR magnetic powder refers to the magnetic powder obtained by hydrogenation-disproportionation-dehydrogenation-recombination) and the like. The quenched magnetic powder can be self-made or commercially available. The preparation process of the quenched magnetic powder can be: (a) batching according to the ratio of each element in the quenched magnetic powder; (b) mixing the prepared raw materials and me...

Embodiment 1

[0042] The commercially available MQU-F magnetic powder was hot-pressed into a preformed blank. The shape of the preformed blank was a cuboid with a cross-section of 40mm×13mm and a thickness of 20mm.

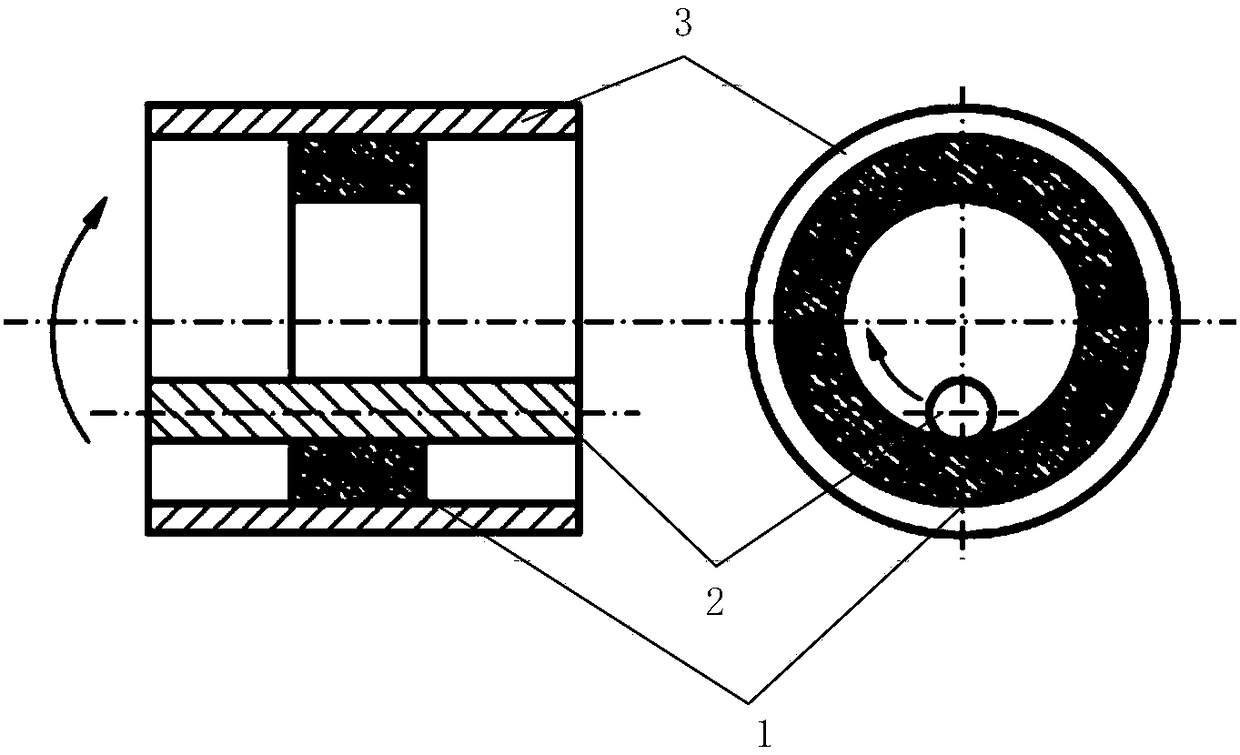

[0043] The preform is placed in a hot-rolling furnace, and the air pressure inside the hot-rolling furnace is reduced to less than 5.0×10 -2 Pa, and then filled with argon. Then heat the preformed blank to about 840°C, and then transfer the preformed blank to such as figure 1 Shown between a pair of rollers 2 that rotate in opposite directions. The distance between the centers of circles of the pair of rolls 2 is 6mm. Finally, a rare earth permanent magnet with a thickness of 6 mm was obtained. The ratio of the cross-sectional area of the rare earth permanent magnet to the cross-sectional area of the preformed blank is 30%. The orientation direction of the lamellar microstructure in the obtained rare earth permanent magnet is perpendicular to the rolling direction.

[...

Embodiment 2

[0049] The preparation method of embodiment 2 rare earth permanent magnet is basically the same as embodiment 1, and difference is: as figure 2 Three sets of rolls 2 are shown (each set of rolls 2 comprising two rolls 2 turning in opposite directions). Finally, a rare earth permanent magnet with a thickness of 6 mm was obtained. The ratio of the cross-sectional area of the rare earth permanent magnet to the cross-sectional area of the preformed blank is 30%.

[0050] The magnetic properties of the obtained rare earth permanent magnets were tested. See Table 2 for the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com