A cable extrusion process

An extrusion process and cable technology, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve problems such as electricity accidents, partial discharge failures, safety accidents, etc., to improve quality and safety, improve Physical properties and the effect of reducing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

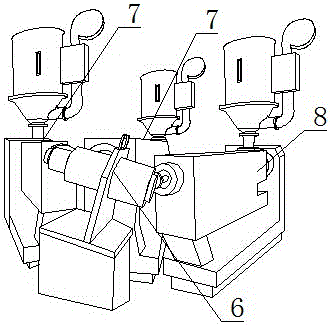

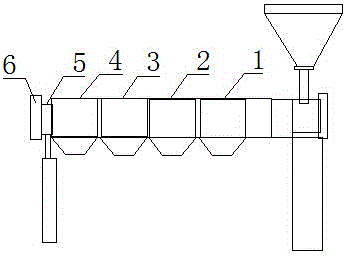

[0040] The diameter of the screw in the extruder is 45mm, and according to the temperature settings of each part of the extruder, the following three embodiments are enumerated:

[0041] Two polyethylene (PVC) sheathed extruders of the heating extruder have the temperature of body one 11 of the extruder 8 to be 150°C, the temperature of body two 12 to be 150°C, the temperature of machine neck 15 to be 150°C, and the machine head The temperature of 16 is 160 DEG C; the temperature of fuselage one 1 of cross-linked polyethylene (XLPE) insulating extruder 7 is 150 DEG C, the temperature of fuselage two 2 is 160 DEG C, the temperature of machine neck 5 is 180 DEG C, machine The temperature of head 6 is 160°C, the elongation of the produced cable under load is 60%, the elongation after cooling is 0, the heat shrinkage is 2.6%, the tensile strength is 8.4MPa, and the elongation at break is is 420%.

[0042] Two polyethylene (PVC) sheathed extruders of the heating extruder have a bo...

Embodiment 2

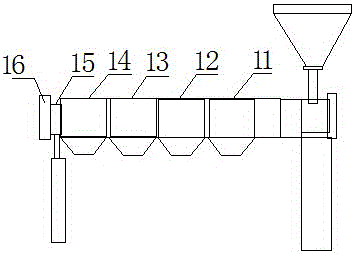

[0045] The diameter of the screw in the extruder is 65mm, and according to the temperature settings of each part of the extruder, the following three embodiments are enumerated:

[0046] The temperature of two polyethylene (PVC) sheathed extruders of the extruder extruder 8 is 150°C for body one 11, the temperature for body two 12 is 150°C, and the temperature for body three 13 is 150°C. The temperature of the neck 15 is 150°C, the temperature of the machine head 16 is 160°C, and the temperature of the die sleeve mouth is 160°C; the temperature of the body-1 of the cross-linked polyethylene (XLPE) insulating extruder 7 is 150°C, The temperature of the second body 2 is 160°C, the temperature of the third body 3 is 170°C, the temperature of the neck 5 is 180°C, the temperature of the head 6 is 190°C, and the temperature of the mold sleeve mouth is 210°C. The produced cable The elongation under load is 60%, the elongation after cooling is 0, the heat shrinkage is 3%, the tensile ...

Embodiment 3

[0050] The diameter of the screw in the extruder is 90mm. According to the temperature settings of each part of the extruder, the following three embodiments are enumerated:

[0051] The temperature of two polyethylene (PVC) sheathed extruders of the extruder extruder 8 is 140°C for body one 11, the temperature for body two 12 is 140°C, and the temperature for body three 13 is 140°C. The temperature of body 4 14 is 140°C, the temperature of machine neck 15 is 150°C, the temperature of machine head 16 is 160°C, and the temperature of die sleeve mouth is 160°C; The temperature of body 1 is 150°C, the temperature of body 2 2 is 160°C, the temperature of body 3 3 is 170°C, the temperature of body 4 4 is 180°C, the temperature of machine neck 5 is 180°C, and the temperature of machine head The temperature of 6 is 190°C, the temperature of the mold sleeve mouth is 210°C, the elongation of the produced cable under load is 60%, the elongation after cooling is 0, the heat shrinkage is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com