Infrared-resistant lens preparation method

A technology of infrared light and lenses, applied in the direction of optical filters, optics, optical components, etc., can solve the problems of affecting the comfort of the wearer, failure of anti-infrared factors, poor thermal conductivity, etc., achieving high market promotion value and excellent protection effect , good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Strengthen the substrate: wash it with clean water, hang it on the appliance to dry at room temperature, soak it in the strengthening liquid (polysiloxane solution) for 120 seconds, and then dry the strengthening solution. Strengthening is to improve the surface properties, making it easier to apply the first layer.

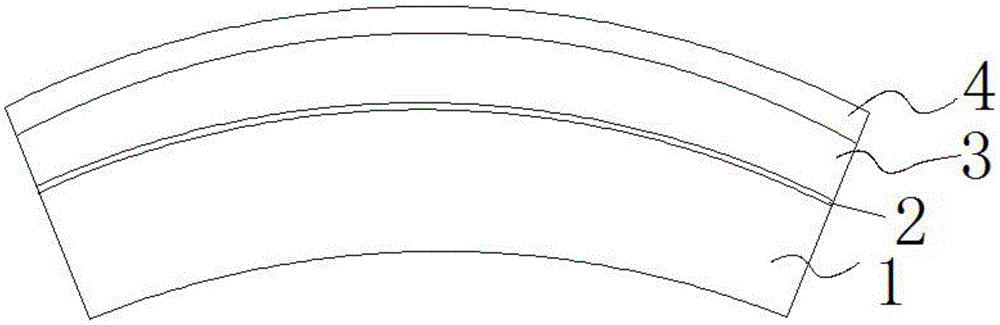

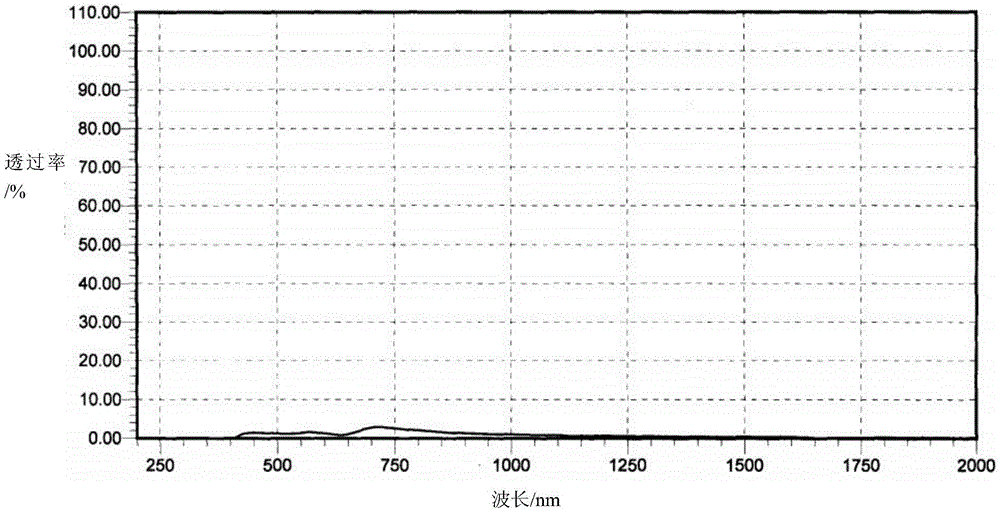

[0028] The vacuum coating machine adopts the vacuum coating machine model LP-1200EBA produced by Xiangzhou Vacuum Machinery (Stock) Co., Ltd. and Longpin Industrial Co., Ltd. to carry out evaporation operations on the lens substrate. The evaporation method in the equipment can choose electron gun evaporation and heating tungsten boat evaporation. In this embodiment, vacuum evaporation is carried out sequentially on one surface of the lens substrate, respectively: the first coating layer is silicon oxide, the second coating layer is copper, and the third coating layer is an aluminum oxide layer.

[0029] The vacuum coating operation of the lens is a well-k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com