A Composite Monitoring Method for Stay Cable Corrosion Based on Stress Concentration and Ultrasonic Guided Wave

An ultrasonic guided wave and stress concentration technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. Ultrasonic detection of blind spots and other problems, to ensure authenticity and reliability, improve reliability, and signal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

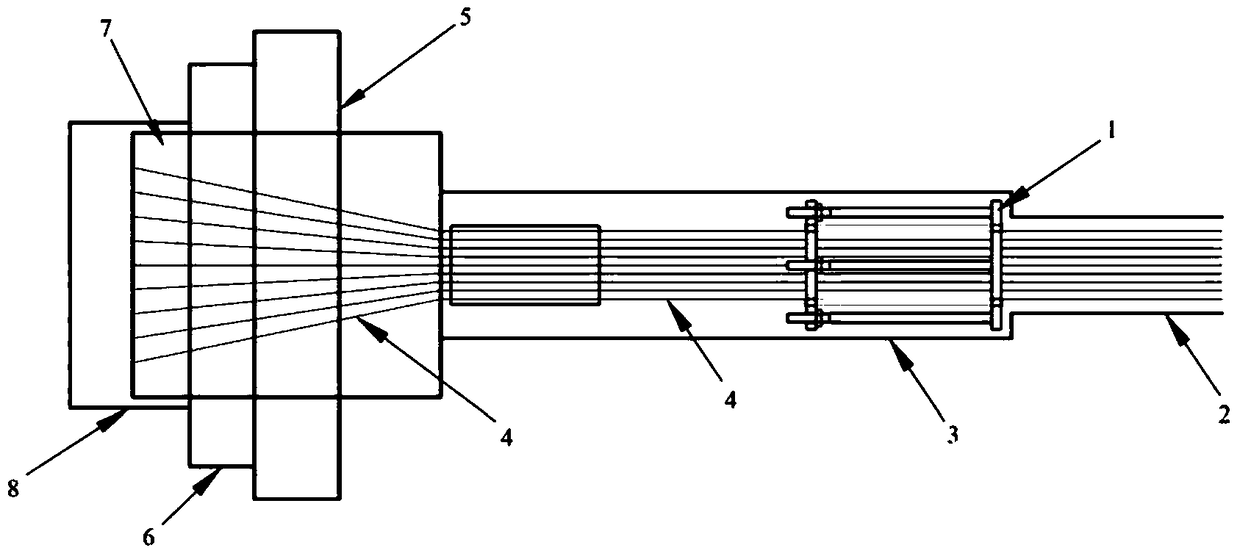

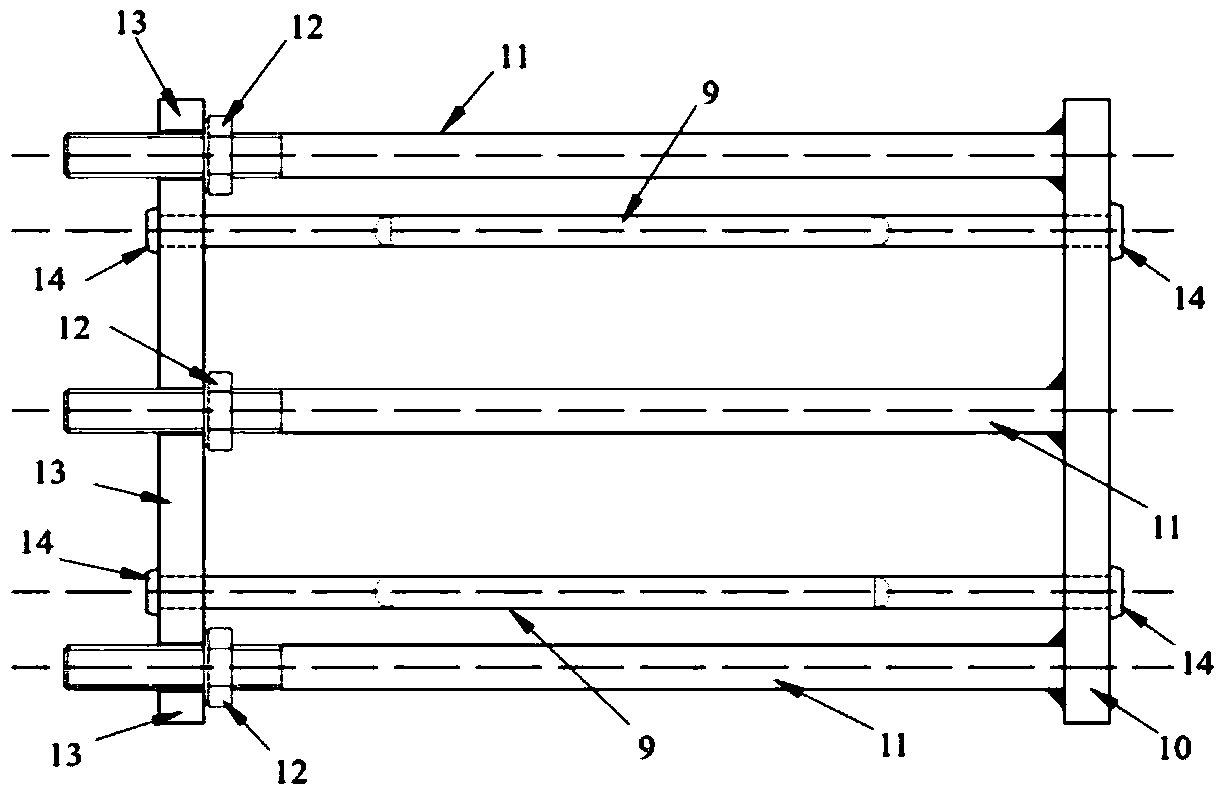

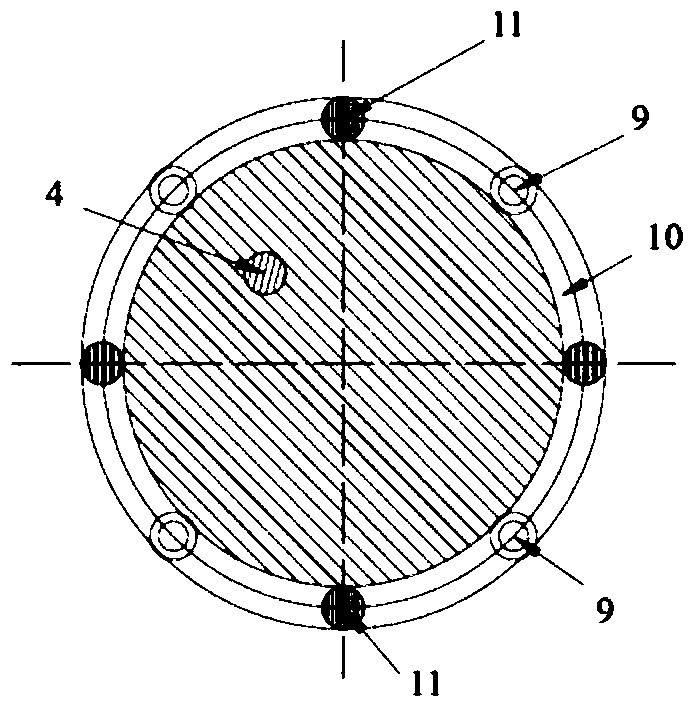

[0025] Embodiment: choose the high-strength steel wire of the same brand used with the stay cable, intercept a certain length and cut the thin slice to form the corrosion sensing unit 9 (such as Figure 4a , shown in b), set continuous strain measuring points 15 at different heights on both sides (such as Figure 4a , Figure 5 ), the continuous strain measuring point 15 adopts a chain strain gauge group, each chain strain gauge group has multiple measuring gauges, and one temperature compensation gauge is used for temperature compensation (the monitored strains below are all strains after compensation), through high The performance glue is pasted at different cross-sectional heights on both sides of the sheet, connected to the strain gauge through welding terminals and wires, and the chain strain gauge group can continuously monitor the average strain of each measuring point in the length direction. A piezoelectric ceramic sheet 16 is pasted on the end of the steel wire shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com