Determination method of sensitivity grade of intergranular corrosion of 5083 alloy sheet materials

A technology of alloy plate and intergranular corrosion, which is applied in the field of metallography, can solve the problems of long sample preparation and detection cycle, and achieve the effect of shortening the judgment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

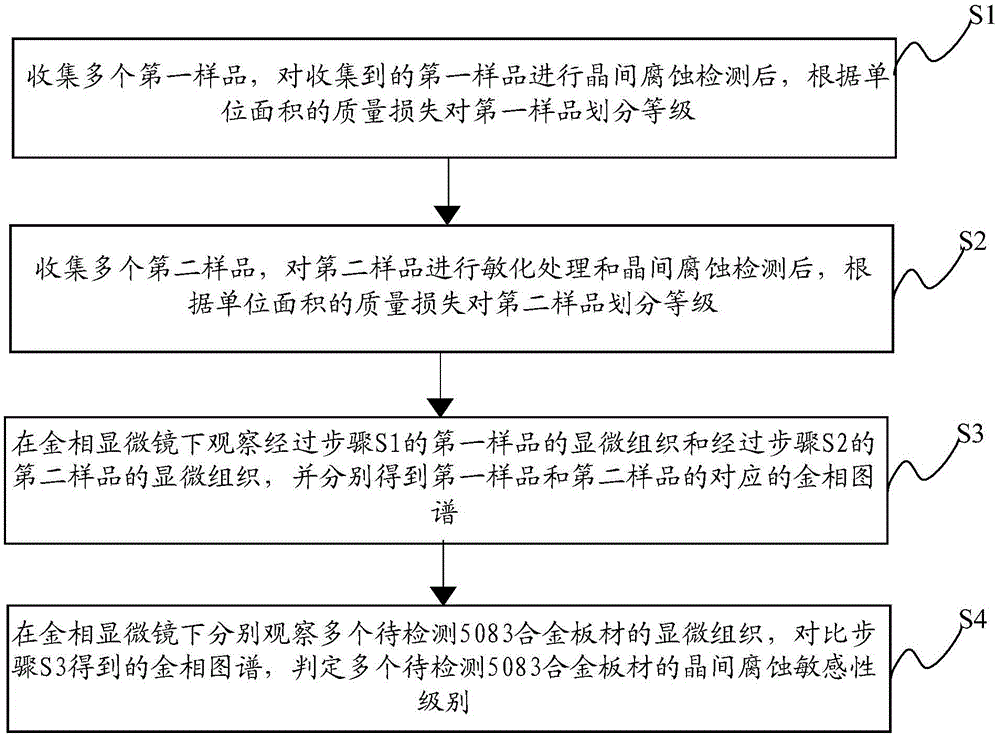

[0029] see figure 1 , is a schematic flow chart of the method for judging the intergranular corrosion sensitivity level of 5083 alloy plate provided by the present invention.

[0030] The invention provides a method for judging the intergranular corrosion sensitivity level of a 5083 alloy plate, comprising the following steps:

[0031] Step S1: collecting a plurality of first samples, and classifying the first samples according to the mass loss per unit area after performing intergranular corrosion detection on the collected first samples;

[0032] Collect a number of first samples of 5083 alloy plates with different specifications and different states. After intergranular corrosion detection is performed on the collected first samples, the first samples are classified according to the quality loss; it should be noted that the classification The grade is to evaluate the mass loss level of the first sample by the mass loss per unit area, and then determine the intergranular co...

Embodiment 2

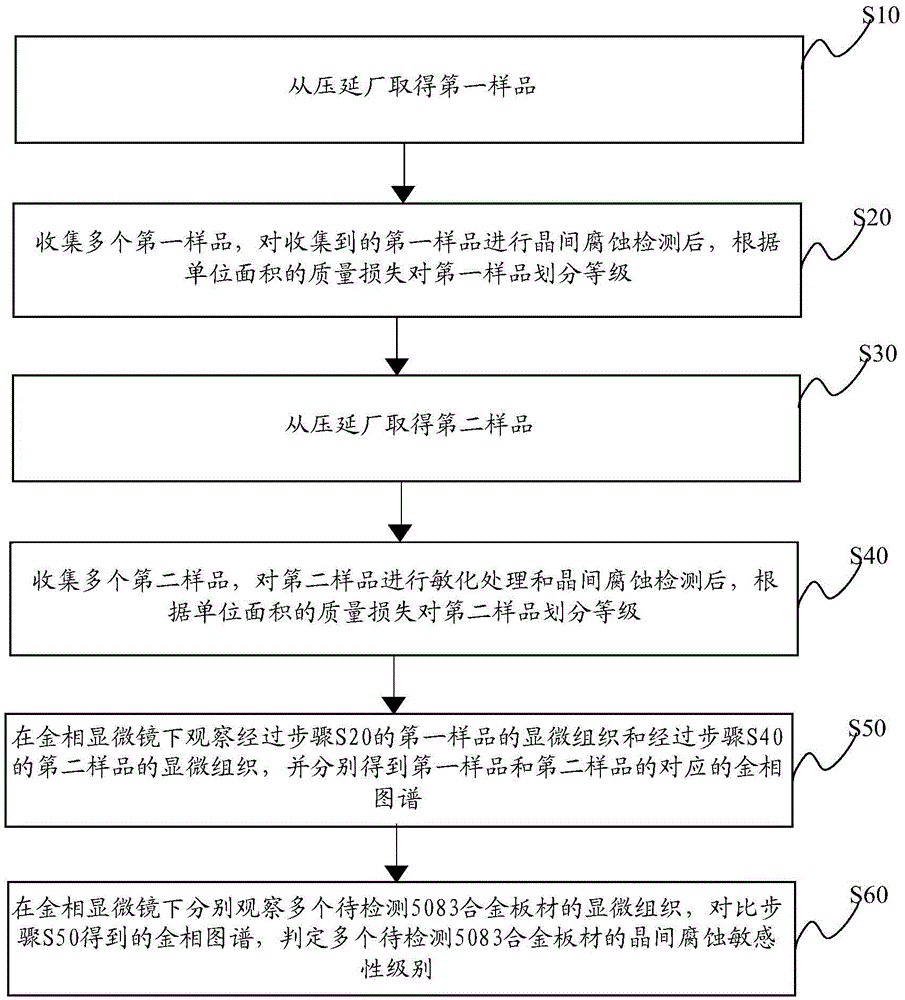

[0039] In yet another embodiment provided by the present invention, the method for judging the intergranular corrosion sensitivity level of the 5083 alloy plate in this embodiment is similar to the method for judging the intergranular corrosion sensitivity level of the 5083 alloy plate in Embodiment 1, and the same points are No more details, just the differences.

[0040] In this embodiment, the method for judging the intergranular corrosion sensitivity level of 5083 alloy plate includes the following steps:

[0041] Step S10: Obtain a first sample from a rolling factory.

[0042] The calendering plant obtained 5083 alloy plate samples.

[0043] Step S20: collecting a plurality of first samples, and classifying the first samples according to the mass loss per unit area after performing intergranular corrosion detection on the collected first samples;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com