Preparation method of a single crystal porous cobaltous oxide nanorod array

A nanorod array and single crystal technology, applied in the field of nanomaterials, can solve the problems of inability to ion exchange synthesis and difficult application, and achieve good application prospects, process stability, and good universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

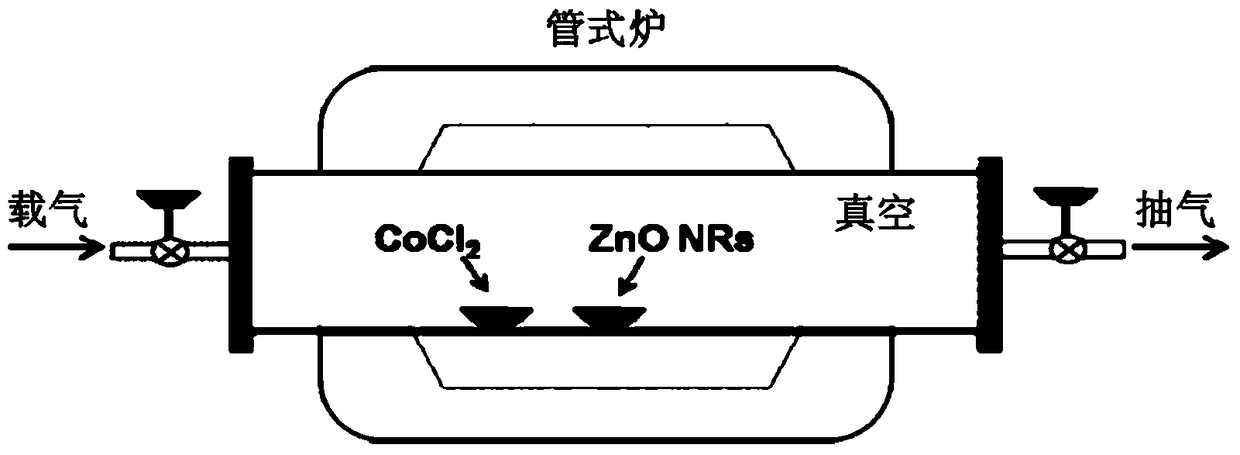

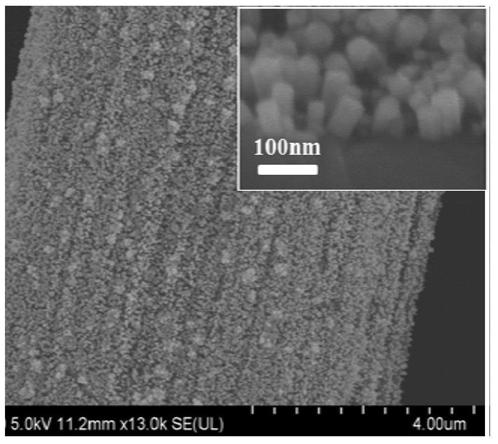

[0033] A Zn seed layer was prepared on the C fiber substrate by magnetron sputtering, the sputtering parameter was 25mA for 400s, and then the growth substrate was annealed at 400°C for 15min in a muffle furnace. Weigh 1.4019g hexamethyltetramine and 2.9749g Zn(NO 3 ) 2 ·6H 2 O, add 400mL deionized water, stir until clear, and prepare 0.25M ZnO hydrothermal growth solution. Place the growth substrate with the growth side facing down and tilt it into the reactor, add growth solution, put the reactor into a steel bottle, add a gasket and tighten it to seal. Put the reaction kettle into a constant temperature drying oven at 100°C, and react for 1 hour. The C fiber substrate prepared with the ZnO nanorod array was taken out, and placed in a muffle furnace for annealing at 500° C. for 1 h. Then place the C fiber substrate in the center of the tube furnace, add 0.2mg CoCl 2 Placed 2cm upstream from the basal position, such as figure 1 As indicated, the reaction furnace was eva...

Embodiment 2

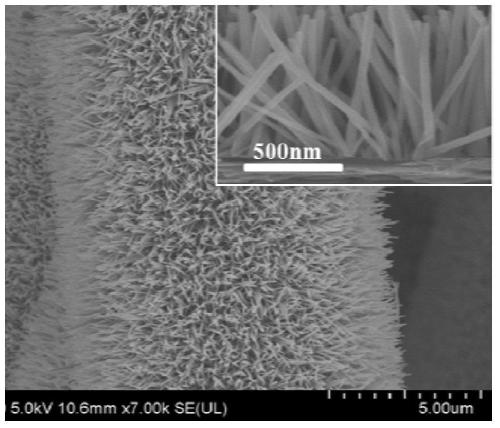

[0036] A Zn seed layer was prepared on the C fiber substrate by magnetron sputtering, the sputtering parameter was 25mA for 400s, and then the growth substrate was annealed at 400°C for 15min in a muffle furnace. Weigh 1.4019g hexamethyltetramine and 2.9749g Zn(NO 3 ) 2 ·6H 2 O, add 400mL deionized water, stir until clear, and prepare 0.25M ZnO hydrothermal growth solution. Place the growth substrate with the growth side facing down and tilt it into the reactor, add growth solution, put the reactor into a steel bottle, add a gasket and tighten it to seal. Put the reaction kettle into a constant temperature drying oven at 100°C, and react for 6 hours. The C fiber substrate prepared with the ZnO nanorod array was taken out, and placed in a muffle furnace for annealing at 500° C. for 1 h. Then place the C fiber substrate in the center of the tube furnace, add 0.2mg CoCl 2 Placed 2cm upstream from the basal position, such as figure 1 As indicated, the reaction furnace was ev...

Embodiment 3

[0039] A Zn seed layer was prepared on the C fiber substrate by magnetron sputtering, the sputtering parameter was 20mA for 800s, and then the growth substrate was annealed at 400°C for 15min in a muffle furnace. Weigh 1.4019g hexamethyltetramine and 2.9749g Zn(NO 3 ) 2 ·6H 2 O, add 200mL deionized water, stir until clear, and prepare 0.5M ZnO hydrothermal growth solution. Place the growth substrate with the growth side facing down and tilt it into the reactor, add growth solution, put the reactor into a steel bottle, add a gasket and tighten it to seal. The reaction kettle was put into a constant temperature drying oven at 100°C, and reacted for 9 hours. The C fiber substrate prepared with the ZnO nanorod array was taken out, and placed in a muffle furnace for annealing at 500° C. for 1 h. Then place the C fiber substrate in the center of the tube furnace, add 0.2mg CoCl 2 Placed 2cm upstream from the basal position, such as figure 1 As indicated, the reaction furnace w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com