Preparation method of 7Ni steel plate for liquefied natural gas storage tank

A technology for liquefied natural gas and storage tanks, which is applied in the field of alloy steel manufacturing, can solve problems such as complex production processes, achieve the effect of reducing alloy costs and facilitating stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

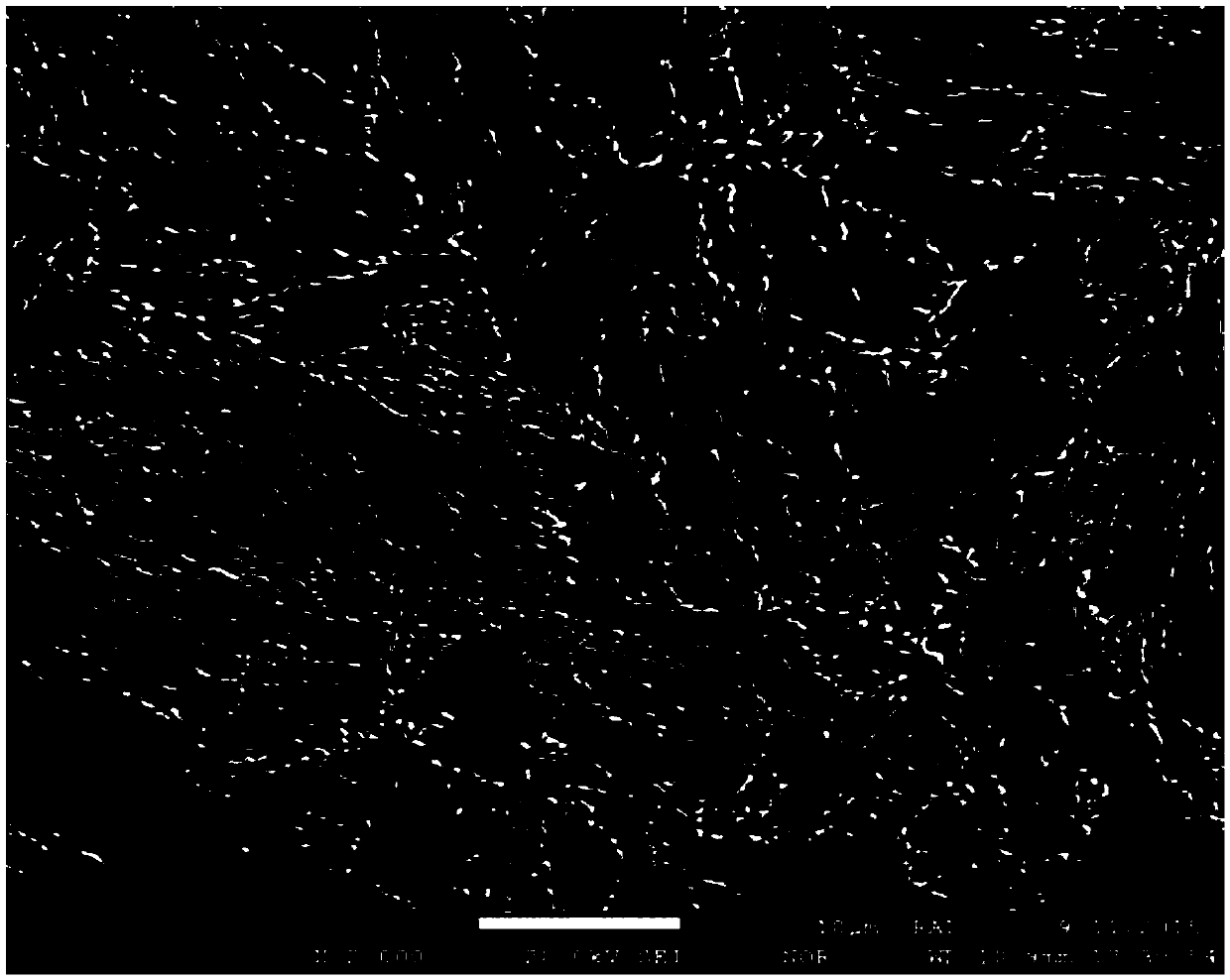

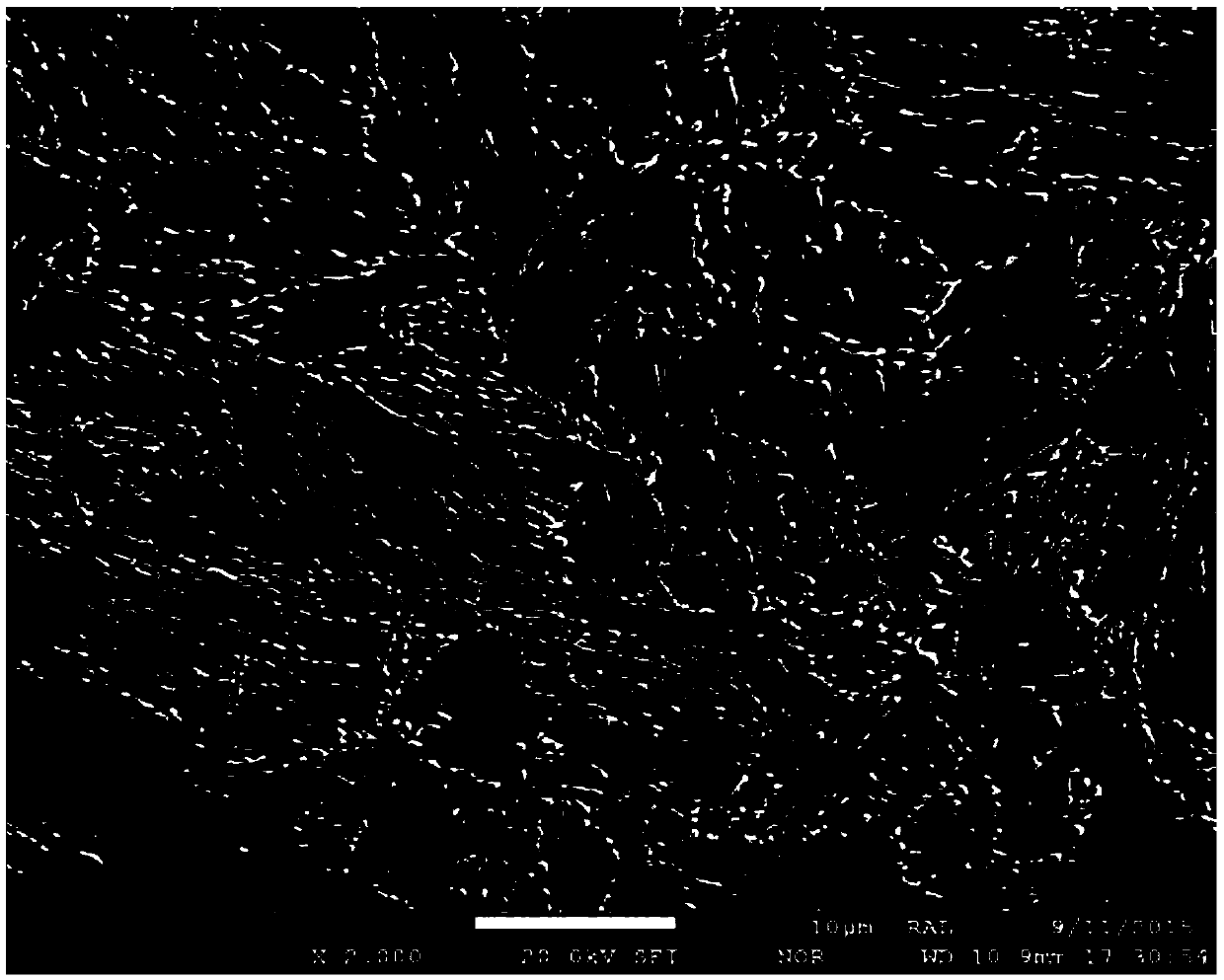

Image

Examples

Embodiment 1

[0041] The preparation method of 7Ni steel plate for liquefied natural gas storage tank comprises the steps:

[0042] Step 1, smelting:

[0043] According to the ratio of 7Ni steel plate for liquefied natural gas storage tank, it is smelted in a 50Kg vacuum induction furnace and cast into a billet. %, S: 0.003%, P: 0.006%, Ni: 6.93%, Cr: 0.40%, Al: 0.035%, the balance is Fe and unavoidable impurities

[0044] Step 2, hot rolling:

[0045] (1) Ingot casting of 7Ni steel plate for LNG storage tank, after heat preservation at 1200°C for 1 hour, the billet is opened into a billet with a thickness of 100mm, and the billet is held at 1200°C for 1 hour;

[0046](2) Rough rolling: Rolling is carried out in the austenite recrystallization zone, the total number of passes is 4 times, the reduction rate of each pass is ≥10%, the cumulative reduction rate is ≥50%, the starting rolling temperature is 1160°C, and the final rolling Rolling temperature 1050℃;

[0047] (3) Finish rolling: ...

Embodiment 2

[0055] The preparation method of 7Ni steel plate for liquefied natural gas storage tank comprises the steps:

[0056] Step 1, smelting:

[0057] According to the ratio of 7Ni steel plate for liquefied natural gas storage tank, it is smelted in a 50Kg vacuum induction furnace and cast into a billet. The composition mass percentage of 7Ni steel plate for liquefied natural gas storage tank is C0.043%, Si0.07%, Mn0.87 %, S0.004%, P0.006%, Ni7.26%, Cr0.53%, Al0.023%, the balance is Fe and unavoidable impurities

[0058] Step 2, hot rolling:

[0059] (1) Ingot casting of 7Ni steel plate for liquefied natural gas storage tank, after heat preservation at 1170°C for 2 hours, the billet is opened into a billet with a thickness of 100mm, and the billet is held at 1160°C for 2 hours;

[0060] (2) Rough rolling: Rolling is carried out in the austenite recrystallization zone, the total number of passes is 4 times, the reduction rate of each pass is ≥10%, the cumulative reduction rate is ≥...

Embodiment 3

[0069] The preparation method of 7Ni steel plate for liquefied natural gas storage tank comprises the steps:

[0070] Step 1, smelting:

[0071] According to the ratio of 7Ni steel plate for liquefied natural gas storage tank, it is smelted in a 50Kg vacuum induction furnace and cast into a billet. The composition mass percentage of 7Ni steel plate for liquefied natural gas storage tank is C0.052%, Si0.05%, Mn0.65 %, S0.003%, P0.006%, Ni7.02%, Cr0.67%, Al0.047%, the balance is Fe and unavoidable impurities

[0072] Step 2, hot rolling:

[0073] (1) Cast an ingot of 7Ni steel plate for LNG storage tank, heat it at 1150°C for 2 hours, open the billet into a billet with a thickness of 100mm, and keep the billet at 1150°C for 2 hours;

[0074] (2) Rough rolling: Rolling is carried out in the austenite recrystallization zone, the total number of passes is 4 times, the reduction rate of each pass is ≥10%, the cumulative reduction rate is ≥50%, the starting rolling temperature is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com