Salt-resistant thickener and salt-resistant recyclable fracturing fluid containing the salt-resistant thickener

A thickening agent and fracturing fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of crops and surface water pollution in the surrounding environment, achieve good salt resistance, reduce risks, and maintain ecological effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

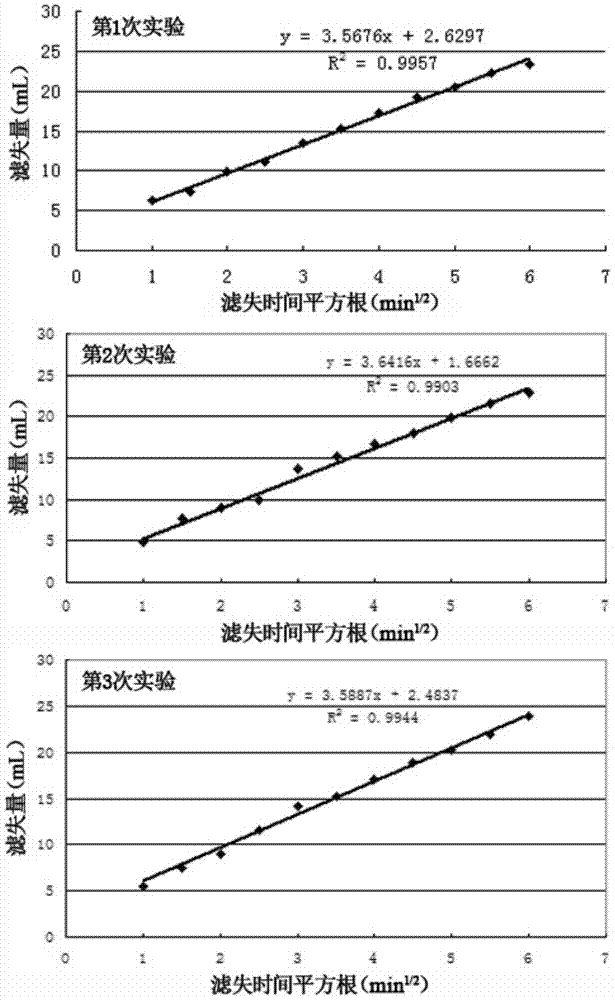

Embodiment 1

[0039] This embodiment provides a kind of anti-salt thickener, and this anti-salt thickener is prepared through the following steps:

[0040] (1) Get 40 parts by weight of isopropanol solution as a dispersant, add 10 parts by weight of small molecule guar gum powder therein, and add 0.5 parts by weight of sodium hydroxide for alkalization, alkalization at 70-80°C 40-50min;

[0041] (2) add the sulfonic acid ester of 0.1 weight part and the propylene oxide of 5 weight parts, heat and stir and react completely;

[0042] (3) neutralize the sodium hydroxide in the solution with 0.5 parts by weight of acetic acid, and add 40 parts by weight of isopropanol solution, filter after stirring, the filtered material is washed and filtered again with isopropanol solution;

[0043] (4) Dry and pulverize at 60°C to obtain a light yellow powder, which is the anti-salt thickener.

[0044] This embodiment also provides a method for preparing a salt-resistant recyclable fracturing fluid, compr...

Embodiment 2

[0048] This embodiment provides a kind of anti-salt thickener, and this anti-salt thickener is prepared through the following steps:

[0049](1) Get 60 parts by weight of isopropanol solution as a dispersant, add 20 parts by weight of small molecule guar gum powder therein, and add 1 part by weight of sodium hydroxide for alkalization, alkalization at 70-80°C 40-50min;

[0050] (2) add the sulfonic acid ester of 1 weight part and the propylene oxide of 10 weight parts, heat and stir and react completely;

[0051] (3) neutralize the sodium hydroxide in the solution with acetic acid of 1 weight part, and add 50 parts by weight of isopropanol solution, filter after stirring, the filtered material is washed and filtered again with isopropanol solution;

[0052] (4) Dry and pulverize at 60°C to obtain a light yellow powder, which is the anti-salt thickener.

[0053] This embodiment also provides a method for preparing a salt-resistant recyclable fracturing fluid, comprising the f...

Embodiment 3

[0057] This embodiment provides a kind of anti-salt thickener, and this anti-salt thickener is prepared through the following steps:

[0058] (1) Get 50 parts by weight of isopropanol solution as a dispersant, add 10 parts by weight of small molecule guar gum powder therein, and add 0.8 parts by weight of sodium hydroxide for alkalization, alkalization at 70-80°C 40-50min;

[0059] (2) Add 0.5 parts by weight of sulfonic acid ester and 5 parts by weight of propylene oxide, heat and stir to react completely;

[0060] (3) neutralize the sodium hydroxide in the solution with the acetic acid of 0.8 weight part, and add 45 parts by weight of isopropanol solution, filter after stirring, the filtered material is washed and filtered again with isopropanol solution;

[0061] (4) Dry and pulverize at 60°C to obtain a light yellow powder, which is the anti-salt thickener.

[0062] This embodiment also provides a method for preparing a salt-resistant recyclable fracturing fluid, compris...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com