Modified carbon black, modified asphalt and preparation method of modified carbon black and modified asphalt

A technology of modified carbon black and modified asphalt, which is applied in chemical instruments and methods, building components, fibrous fillers, etc. The performance of photoaging, the low cost, the effect of improving the anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

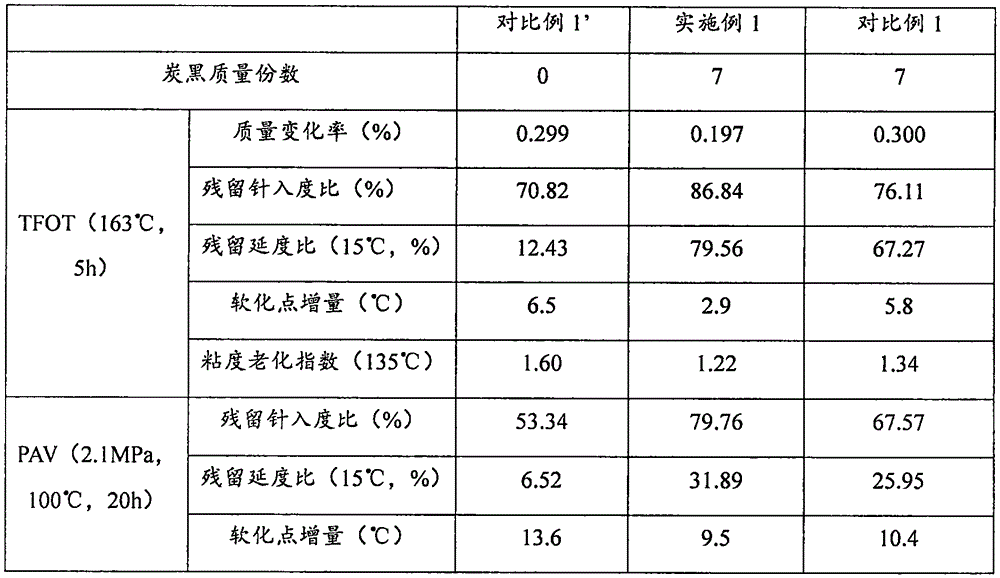

Embodiment 1

[0032] A modified carbon black that can be used as an asphalt additive is prepared from waste rubber through anaerobic high-temperature pyrolysis, washed with detergent, oxidized with an oxidant and activated with a surfactant. The preparation method of this modified carbon black is specifically as follows:

[0033] Using waste rubber as raw material, it is pyrolyzed at 510°C under anaerobic conditions, and then granulated to form microspherical carbon black with a diameter of 30nm. Pressure filtration, remove its organic impurity, in the Erlenmeyer flask that connects spherical condensing pipe, add the product that 50g washes and handle and concentration is the nitric acid 500ml of 68%, by magnetic stirrer, the mixture is stirred at 90 ℃ temperature for 2h, After cooling to room temperature, filter, wash the filtrate repeatedly with deionized water until neutral, dry it in a constant temperature drying oven at 100°C, and put it in a desiccator for constant weight;

[0034] A...

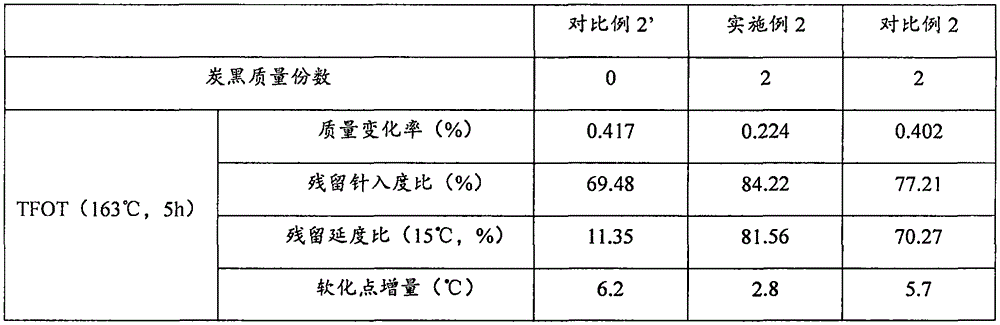

Embodiment 2

[0047] A modified carbon black that can be used as an asphalt additive is prepared from waste rubber through anaerobic high-temperature pyrolysis, washed with detergent, oxidized with an oxidant and activated with a surfactant. The preparation method of this modified carbon black is specifically as follows:

[0048] Using waste rubber as raw material, it is pyrolyzed at 510°C under anaerobic conditions, and then granulated to form microspherical carbon black with a diameter of 50nm. Pressure filtration to remove organic impurities. In the Erlenmeyer flask connected to the spherical condenser, add 50g of washed carbon black and 500ml of concentrated nitric acid with a concentration of 60%, stir the mixture at 70°C for 3h by a magnetic stirrer, and filter after cooling to room temperature. The filtrate was repeatedly washed with deionized water to neutrality, dried in a constant temperature drying oven at 100°C, and placed in a desiccator for constant weight.

[0049] Add 5g o...

Embodiment 3

[0061] A modified carbon black that can be used as an asphalt additive is prepared from waste rubber through anaerobic high-temperature pyrolysis, washed with detergent, oxidized with an oxidant and activated with a surfactant. The preparation method of this modified carbon black is specifically as follows:

[0062] Using waste rubber as raw material, it is pyrolyzed at 510°C under anaerobic conditions, and then granulated to form microspherical carbon black with a diameter of 40nm. Pressure filtration to remove organic impurities. In the Erlenmeyer flask connected with spherical condenser, add 50g of treated carbon black and 500ml of nitric acid with a concentration of 65%, stir it at 80°C for 3h with a magnetic stirrer, filter it after cooling to room temperature, and use it repeatedly The filtrate was washed with deionized water until neutral, dried in a constant temperature drying oven at 100°C, and placed in a desiccator for constant weight.

[0063] Add 5g of carbon bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com