Purification method for glufosinate-ammonium

A purification method and glufosinate-ammonium technology are applied in the purification field of chemicals, which can solve the problems of high cost, large solvent and energy consumption, long process route and the like, and achieve the effects of simple steps, high safety and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

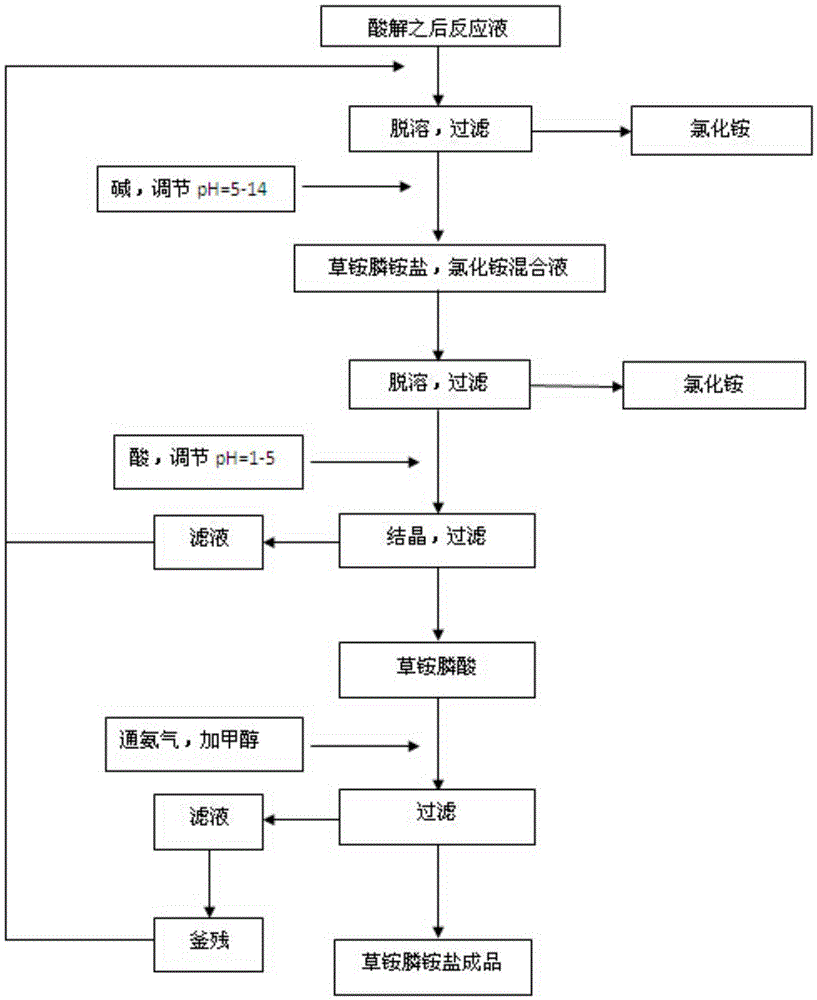

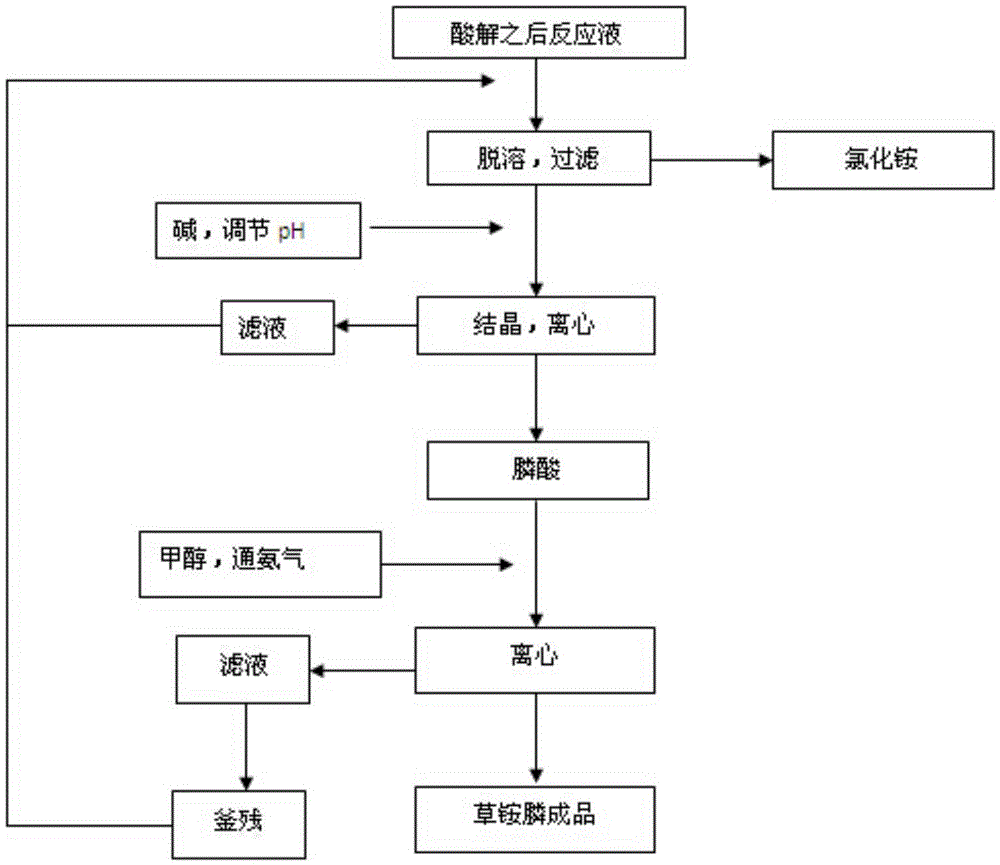

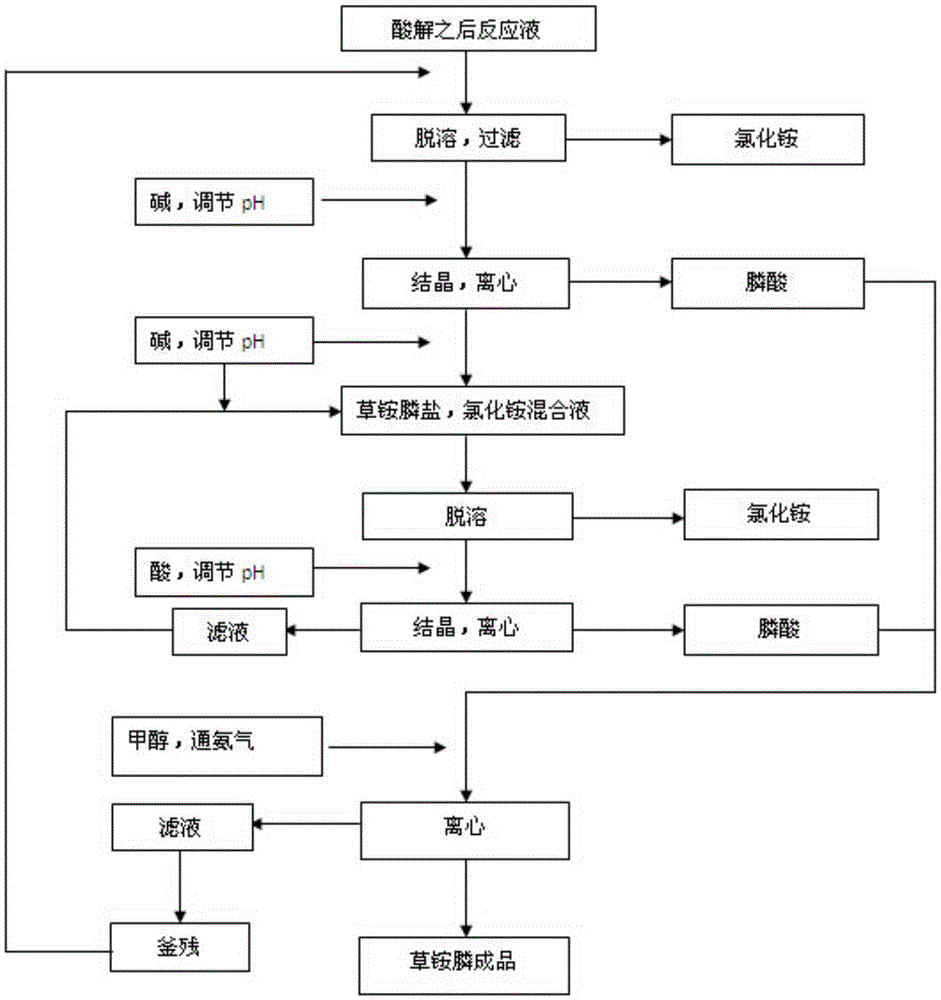

[0044] An embodiment, as attached figure 1 Shown:

[0045] Step (1), heating the acid-hydrolyzed glufosinate-ammonium hydrochloride reaction solution to remove low-boiling point organic solvents and a part of water, and filtering to remove part of ammonium chloride and other insoluble impurities;

[0046] Step (2), add alkali to the filtrate obtained in step (1), adjust the pH to 5~14 for reaction, then heat and distill part of the water, filter to remove ammonium chloride and other insoluble impurities, then add acid, adjust the pH to 1 to 5 are reacted, and then filtered, washed, and dried to obtain the glufosinate-ammonium acid; the filtrate obtained in step (2) is combined with the glufosinate-ammonium hydrochloride reaction solution in step (1);

[0047] Step (3), dissolving the glufosinate-ammonium acid obtained in step (2) in a solvent, and then introducing ammonia gas to carry out a salt-forming reaction, to precipitate glufosinate-ammonium solids, and then filter, wa...

Embodiment 1

[0058] The reaction solution of glufosinate-ammonium hydrochloride (1000 grams, including 300 grams of glufosinate-ammonium hydrochloride) obtained by acid hydrolysis was heated to 110°C, low-boiling point organic matter and part of water (100g) were distilled off, cooled to 30°C, and dripped Add a mixed solution of 5 grams of glycine and 30 grams of ammonia water, adjust the pH=1, react for 1 hour, crystallize, filter, wash with methanol, and dry to obtain 30 grams of off-white glufosinate-ammonium acid with a yield of 12% and a purity of 95%. The filtrates were combined for the next step.

Embodiment 2

[0062] Add a certain amount of ammonia water dropwise to the filtrate (865 g) obtained in Example 1, adjust pH = 10, heat to 110°C, distill off part of the water (350g), cool to 30°C, filter to remove insoluble ammonium chloride, etc. Add a certain amount of hydrochloric acid dropwise to the remaining filtrate, adjust the pH=1, crystallize, filter, wash with methanol, and dry to obtain 215 grams of off-white glufosinate-ammonium acid, with a yield of 97% and a purity of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com