Photocatalyst diatom-mud lightweight high-strength plate

A technology of diatom mud and high-strength board, which is applied in the field of building materials, can solve the problems of no removal function and no inhibition of bacterial reproduction, etc., and achieve the effects of super long life, heat insulation, energy saving, thermal conductivity, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A light-weight high-strength plate of photocatalyst diatom ooze is made of a substrate and a photocatalyst layer coated on the surface of the substrate;

[0037] The composition and mass percentage of the substrate are as follows:

[0038] (ⅰ) Tertiary algal earth: 40%;

[0039] (ii) quicklime: 15%;

[0040] (ⅲ) Cement: 30%;

[0041] (ⅳ) Reinforcing fiber: 15%;

[0042] The composition and mass percentage of described photocatalyst layer are as follows:

[0043] (a) Graphite phase carbon nitride (g-C3N4): 0.3%;

[0044] (b) Surfactant: 10%;

[0045] (c) Adhesive: 0.1%; the balance is water.

[0046] The reinforcing fiber is wood pulp;

[0047] The particle size of the graphite phase carbon nitride (g-C3N4) is 50μ;

[0048] Described surfactant is polyethylene glycol;

[0049] The binder is polyvinyl alcohol.

[0050] A method for preparing a photocatalyst diatom mud lightweight high-strength board, the steps and conditions are as follows:

[0051...

Embodiment 2

[0064] Embodiment 2 A light-weight high-strength plate of photocatalyst diatom mud is made of a substrate and a photocatalyst layer coated on the surface of the substrate;

[0065] The composition and mass percentage of the substrate are as follows:

[0066] (ⅰ) Tertiary algal earth: 50%;

[0067] (ii) Quicklime: 10%;

[0068] (ⅲ) Cement: 20%;

[0069] (ⅳ) Reinforcing fiber: 20%;

[0070] The composition and mass percentage of described photocatalyst layer are as follows:

[0071] (a) Graphite phase carbon nitride (g-C3N4): 5%;

[0072] (b) Surfactant: 5%;

[0073] (c) Adhesive: 3%; the balance is water.

[0074] The reinforcing fiber is straw paddle;

[0075] The particle size of the graphite phase carbon nitride (g-C3N4) is 5μ;

[0076] Described surfactant is polyethylene glycol;

[0077] The adhesive is 108 glue.

[0078] The preparation method is the same as in Example 1.

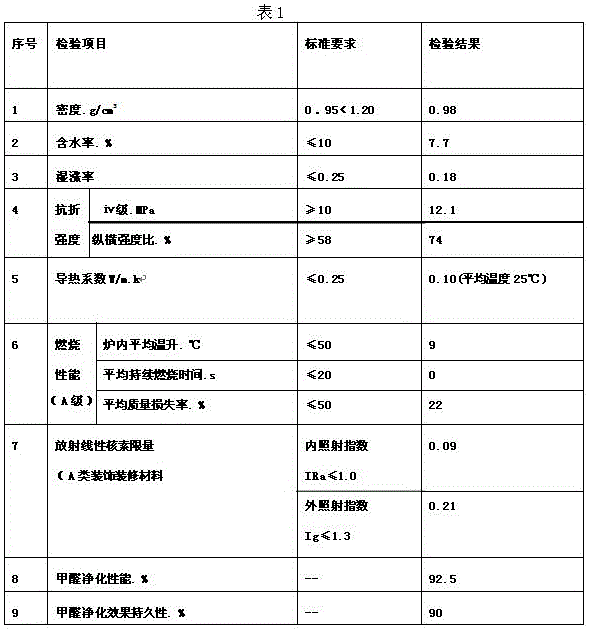

[0079] A light-weight high-strength board made of photocatalyst diatom mud prepared in E...

Embodiment 3

[0083] Embodiment 3 A light-weight high-strength plate of photocatalyst diatom ooze is made of a substrate and a photocatalyst layer coated on the surface of the substrate;

[0084] The composition and mass percentage of the substrate are as follows:

[0085] (ⅰ) Tertiary algal earth: 45%;

[0086] (ii) quicklime: 13%;

[0087] (ⅲ) Cement: 25%;

[0088] (ⅳ) Reinforcing fiber: 17%;

[0089] The composition and mass percentage of described photocatalyst layer are as follows:

[0090] (a) Graphite phase carbon nitride (g-C3N4): 3%;

[0091] (b) Surfactant: 10%;

[0092] (c) Adhesive: 5%; the balance is water. The preparation method is the same as in Example 1.

[0093] The composition and mass percentage of described photocatalyst layer are as follows:

[0094] (a) Graphite phase carbon nitride (g-C3N4): 0.3-5%;

[0095] (b) Surfactant: 0.2-10%;

[0096] (c) Binder: 0.1-5%; the balance is water.

[0097] The reinforcing fiber is glass fiber;

[0098] The particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com