Heating temperature control device and RO (reverse osmosis) water purification system adopting same

A technology of temperature control device and water purification system, applied in the field of heating temperature control device and reverse osmosis water purification system, can solve the problems of complicated operation, long waiting time, inaccurate temperature control, etc., and achieve accurate temperature control, fast water output, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

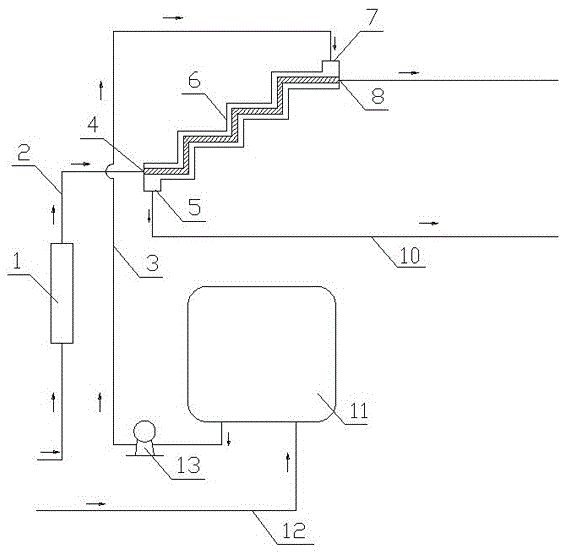

[0024] Embodiment 1, a heating temperature control device, figure 1 It is the structural representation of embodiment 1. A constant temperature water tank 11 and a double-layer cooling coil 6 are provided, and the constant temperature water tank 11 is provided with a water inlet and a heat exchange outlet pipe 3 . A water inlet pipe 12 is connected to the water inlet. One end of the double-layer cooling coil 6 is provided with a water inlet 4 and a heat exchange outlet 5 , and the other end is provided with a water outlet 8 and a heat exchange inlet 7 . The water inlet 4 is connected with a water inlet pipe 2, and an electric heater 1 is arranged on the water inlet pipe 2. The heat exchange inlet 7 is connected to the heat exchange outlet pipe 3 , and the heat exchange outlet pipe 3 is provided with a first water pump 13 .

[0025] When in use, water is supplied to the constant temperature water tank 11 through the water inlet pipe 12. The water temperature in the constant t...

Embodiment 2

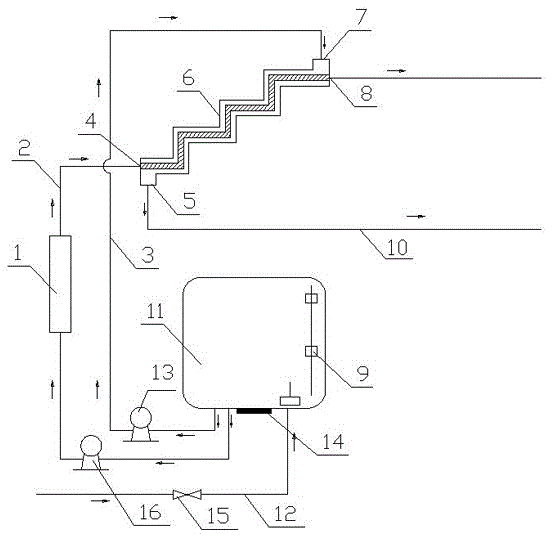

[0026] Embodiment 2, in a heating and temperature control device as described in Embodiment 1, the water inlet pipe 2 is connected to the constant temperature water tank 11, and the water inlet pipe 2 between the electric heater 1 and the constant temperature water tank 11 is equipped with a second water pump 16. A water level switch 9 is provided in the constant temperature water tank 11, and a water supply solenoid valve 15 is provided on the water inlet pipe 12, and the water supply solenoid valve 15 is controlled to be switched on and off by the water level switch 9. On constant temperature water tank 11, PTC heating element 14 is also housed. The constant temperature water tank 11 is provided with an insulating layer. figure 2 It is the structural representation of embodiment 2.

[0027] During use, when the water level in the constant temperature water tank 11 was lower than the low water level of the water level switch 9, the water solenoid valve was opened, and the ...

Embodiment 3

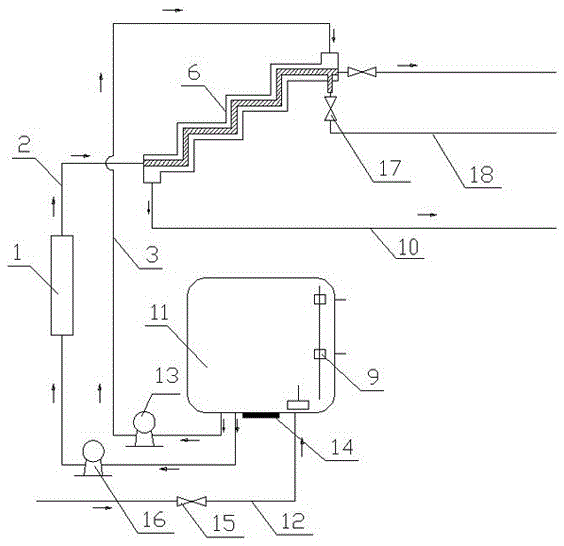

[0028] Embodiment 3, in a heating and temperature control device as described in Embodiment 2, the water outlet 8 is connected with a drainage branch pipe 18, the drainage branch pipe 18 is provided with a drainage solenoid valve 17, and the water outlet 8 is equipped with a water solenoid valve. valve. image 3 It is the structural representation of embodiment 3.

[0029] After each water intake, the water solenoid valve is closed, and a certain amount of water is still stored in the double-layer cooling coil 6 between the electric heater 1 and the water solenoid valve. In order to ensure that the next water intake can accurately obtain the set temperature After each water intake action is completed, the drain solenoid valve 17 is opened to drain the stored water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com