Pneumatic precise filling machine

A filling machine and air pressure technology, which is applied in the field of improvement and invention of air pressure precision filling machines, can solve the problems of difficult processing technology, large errors, leakage measurement, etc., and achieve outstanding substantive features, good economic benefits, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

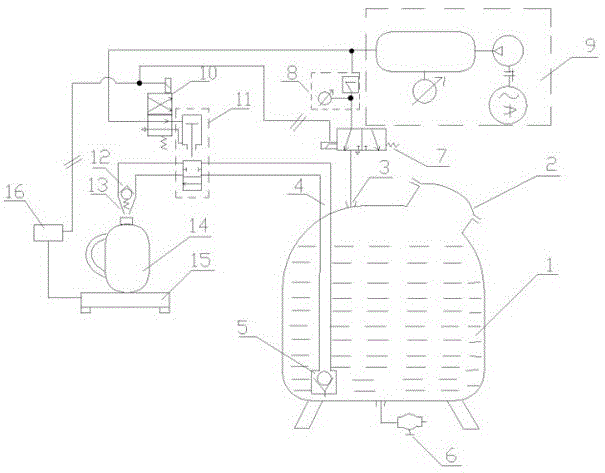

[0016] Embodiment one, see appendix figure 1 , the electric control switch includes a second solenoid valve 10 and an air control on-stop valve 11, the air control on-stop valve 11 is arranged on the upper end of the liquid riser 4, the air control on-off valve 11 communicates with the air pump 9 through the air pipe, and the second electromagnetic A valve 10 is provided on this trachea. When working, the second solenoid valve 10 controls the opening and closing of the air pipe, and realizes the on-off of the air-controlled on-off valve 11 to control the opening and closing of the upper end of the riser pipe 4, wherein the air-operated on-off valve 11 is a valve driven by a cylinder. Body, the cylinder is connected with the air pipe.

Embodiment 2

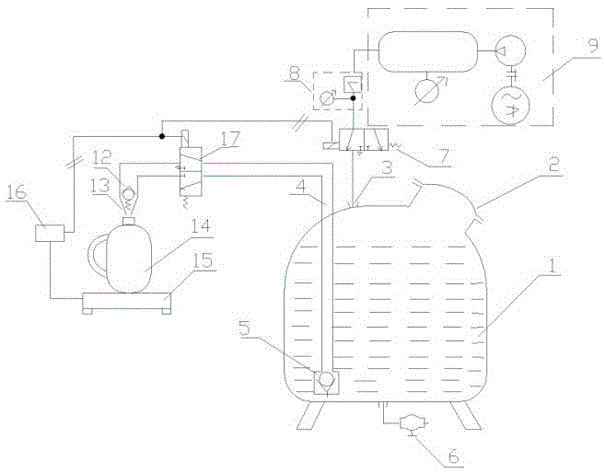

[0017] Embodiment two, see appendix figure 2 , the electronically controlled switch can also be a separate third electromagnetic valve 17 to control the opening and closing of the upper end of the riser pipe 4 .

[0018] In the present invention, preferably, a check valve 5 is provided at the lower end of the liquid riser 4 to prevent the liquid from flowing back. The filling nozzle 13 is provided with an anti-drip one-way pressure valve 12 to prevent the filling liquid from dripping onto the electronic scale 15 when the bottle is replaced, thereby affecting the next weighing measurement. The bottom of the liquid storage tank 1 is provided with a cleaning discharge port, and the discharge port is provided with a ball valve 6 switch, which facilitates the cleaning of the liquid storage tank 1 and meets the needs of the same liquid storage tank 1 for filling different liquids. The air pump 9 is a combination of frequency modulation motor air pump 9, which realizes the adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com