Environment-friendly 3D printing system

A 3D printing, environment-friendly technology, applied in the field of 3D printing, can solve problems such as endangering the life of operators, safety accidents, and danger of operators, and achieve the effect of solving the problem of littering plastic bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

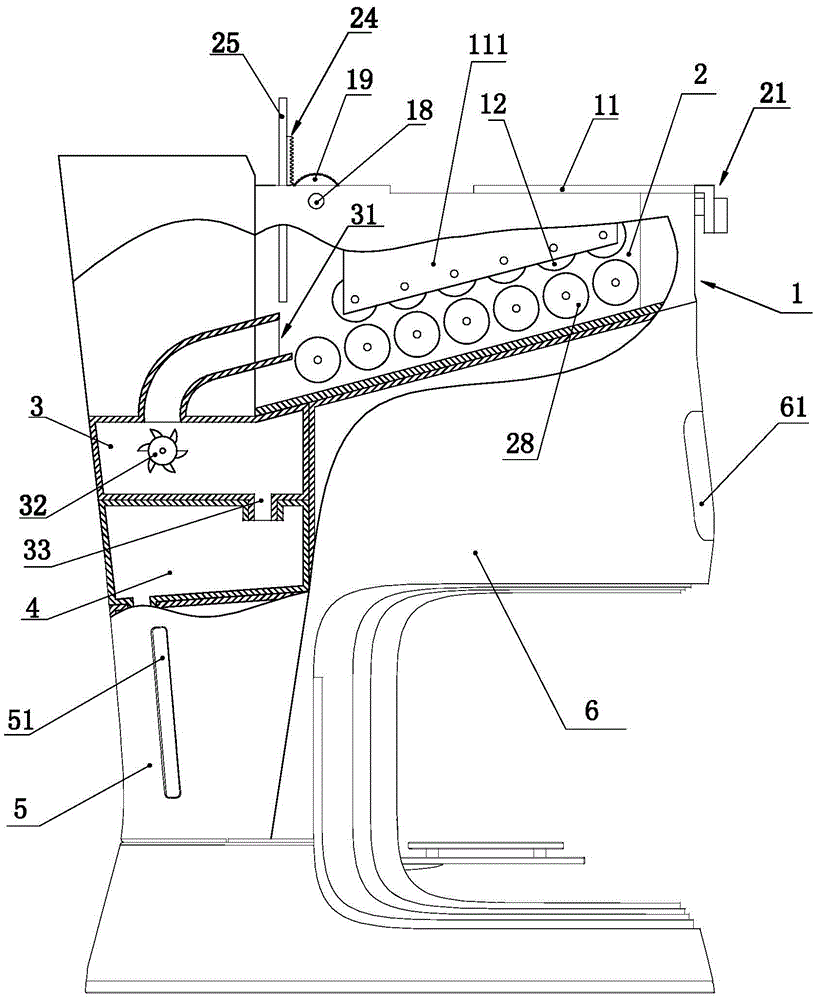

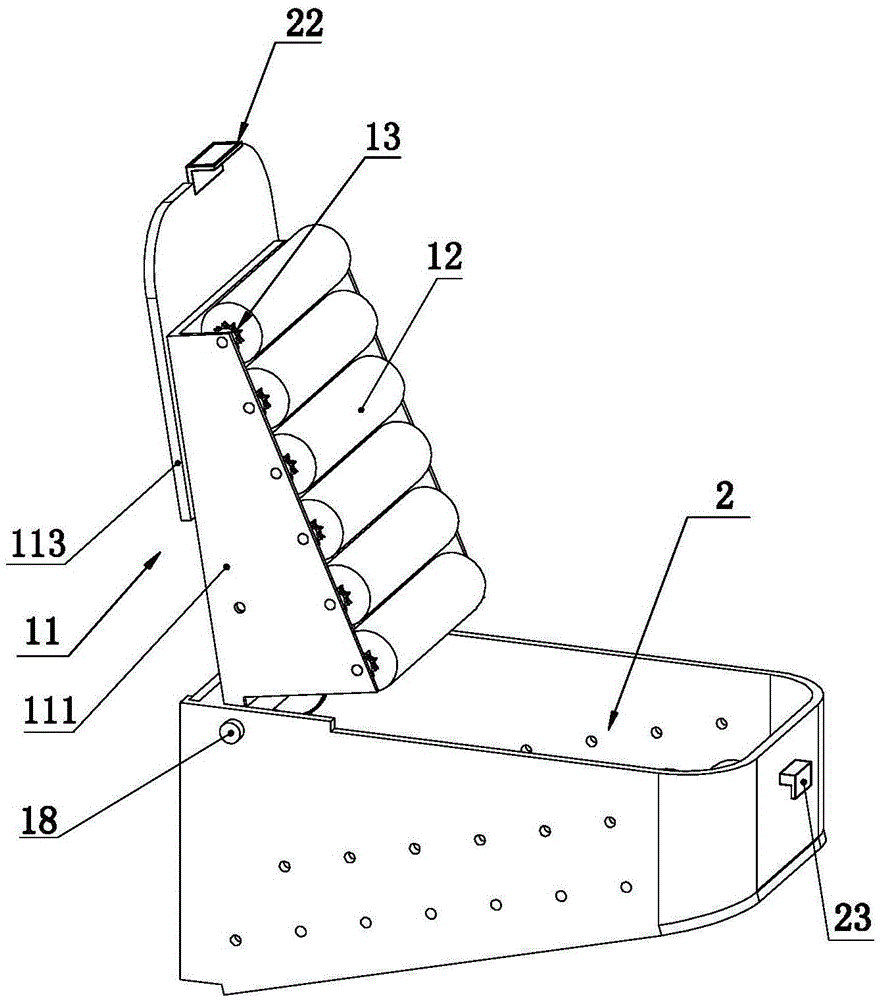

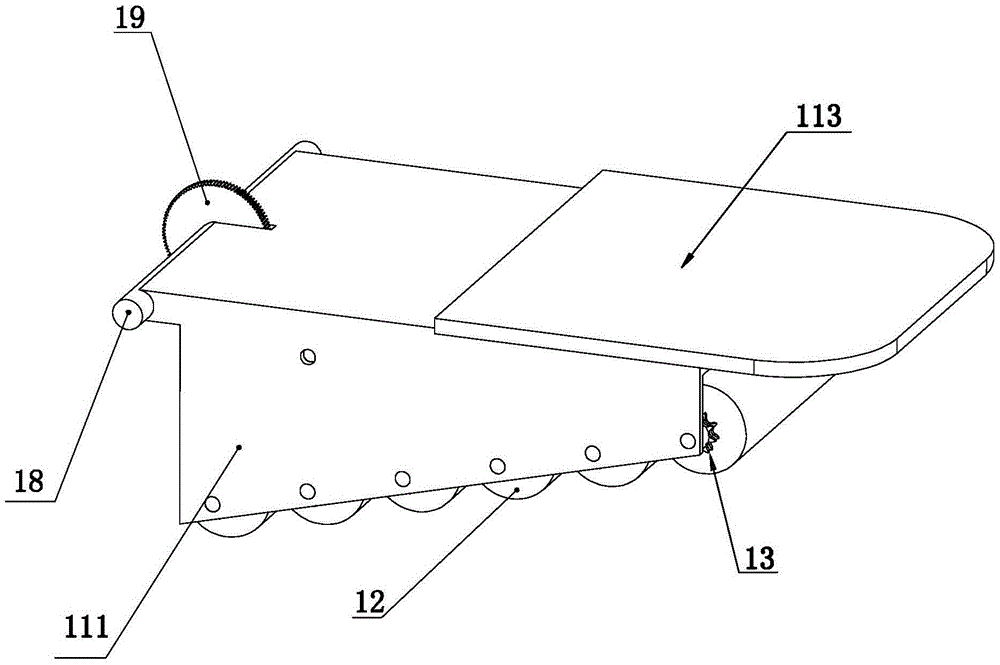

[0023] The present invention mainly includes feeder 1, top cover 11, first roller 12, double sprocket 13, driven sprocket 14, driving chain 15, driving sprocket 16, motor 17, rotating shaft 18, gear 19, feed bin 2, hasp 21, rack 24, baffle plate 25, plastic pulverizer 3, high temperature melting machine 4, material storage box 5 and printer 6, in order to illustrate the present invention better, below in conjunction with accompanying drawing, this utility model is done in detail instruction of.

[0024] Such as figure 1 , Figure 6 As shown, the top cover 11 includes a first side plate 111, a second side plate 112 and a top plate 113, as figure 2 As shown, a number of first rollers 12 are rotatably installed between the first side plate 111 and the second side plate 112 of the top cover 11, as Figure 5 As shown, a layer of non-slip rubber 7 is fixedly connected to each first roller by glue sticking, the axes of any two first rollers are always kept parallel, and the axes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com