Mobile LPG bottle group gasification device and gasification method thereof

A gasification device and mobile technology, applied in the field of LPG gasification, can solve the problems of inability to meet mobile gas supply, poor mobile performance, etc., and achieve the effects of ensuring safety, favorable production and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

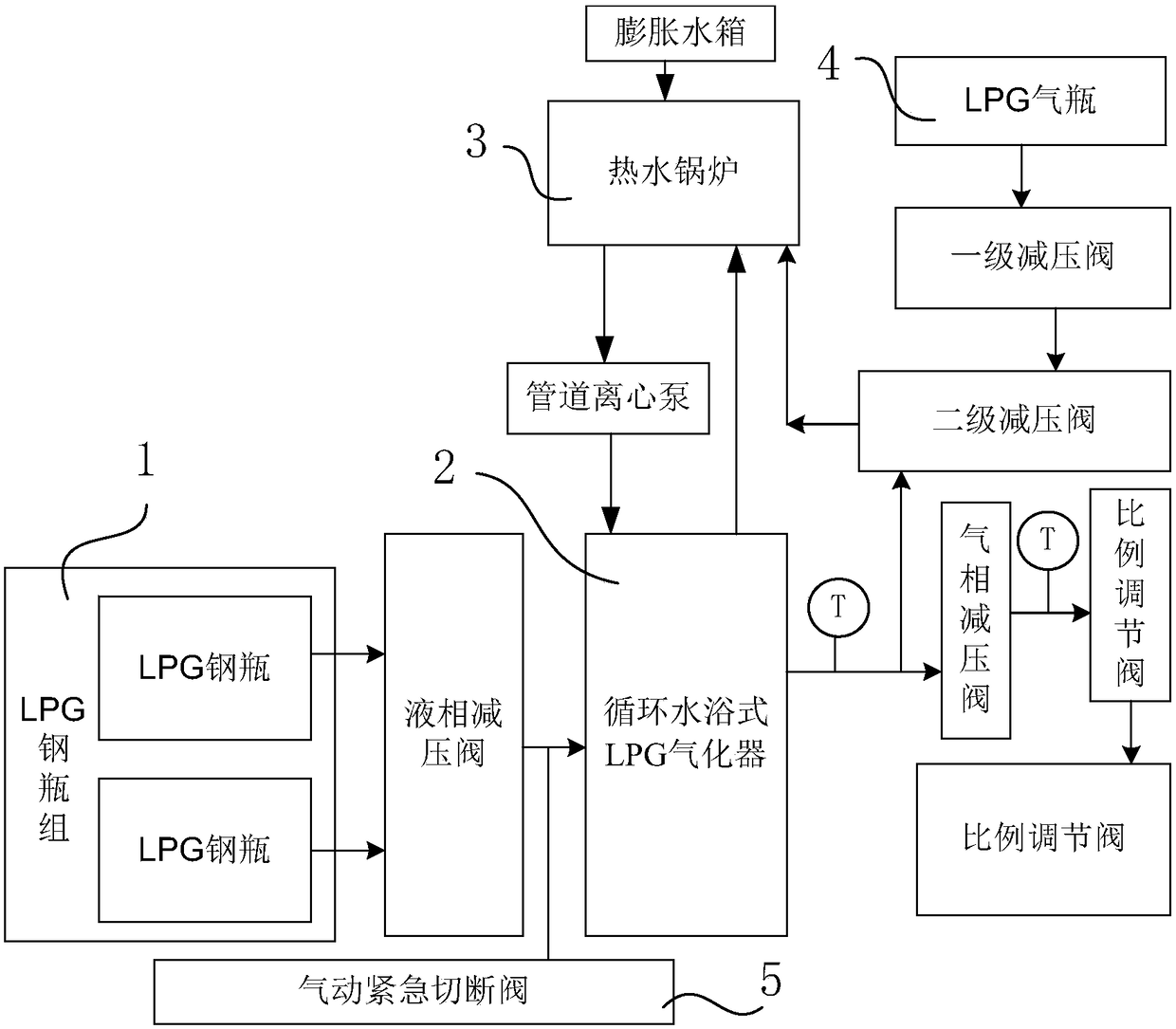

[0040] A mobile LPG bottle group gasification device, such as figure 1 As shown, it includes the LPG cylinder group 1, the circulating water-bath LPG gasifier 2 that communicates with the LPG cylinder group 1 through the main pipeline and provides users with gas phase gas, and the hot water boiler that provides hot water for the circulating water-bath LPG gasifier 2 3. The LPG gas cylinder 4 that provides combustion energy for the hot water boiler 3 .

[0041] In this embodiment, the hot water boiler 3 has an inlet pipe, a water inlet pipe, a water outlet pipe and a return water pipe, and the circulating water bath type LPG vaporizer 2 has a water inlet pipe, a liquid inlet pipe, a water outlet pipe and a gas outlet pipe.

[0042] The water inlet pipe of the circulating water bath type LPG gasifier 2 is connected with the water outlet pipe of the hot water boiler 3, and the water outlet pipe of the circulating water bath type LPG gasifier 2 is connected with the return water p...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the structure before and after the circulating water bath type LPG gasifier 2 is further optimized in this embodiment, and the specific settings are as follows:

[0046] The liquid inlet pipeline of the circulating water bath type LPG gasifier 2 communicates with the LPG cylinder group 1 through the liquid phase pressure reducing valve, and the gas phase pressure reducing valve is also arranged on the gas outlet pipeline of the circulating water bath type LPG gasifier 2, and the liquid phase reducing The pressure of the pressure valve output liquid is 0.1-0.3Mpa, and the pressure of the gas-phase pressure reducing valve output gas is 13-15Kpa. In this embodiment, the pressure of the output liquid from the liquid phase pressure reducing valve is preferably 0.2Mpa, and the pressure of the gas output from the gas phase pressure reducing valve is preferably 14Kpa.

[0047] Through the setting of the above struc...

Embodiment 3

[0049] The difference between this embodiment and Embodiment 2 is that this embodiment further optimizes the structural settings, and the specific settings are as follows:

[0050] Such as figure 1 As shown, the outlet pipeline of the LPG cylinder 4 is connected with a primary pressure reducing valve and a secondary pressure reducing valve in sequence, and the outlet of the secondary pressure reducing valve communicates with the intake pipeline of the hot water boiler 3 . The gas outlet pipeline of the circulating water bath type LPG gasifier 2 is sequentially connected with a gas phase pressure reducing valve and a proportional regulating valve, and the inlet of the gas phase pressure reducing valve is also communicated with the inlet of the secondary pressure reducing valve. An emergency shut-off valve 5 is arranged on the main pipeline, and a temperature transmitter interlocked with the emergency shut-off valve 5 is also arranged on the gas outlet of the circulating water b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com