Adhesive system for improving safety performance of press-packed pbx explosive, preparation method and application thereof

A technology of safety performance and system, applied in the direction of explosives, non-explosive/non-thermal agent components, non-explosive fillers/gelling agents/thickeners, etc., can solve problems such as potential safety hazards, combustion to detonation, etc. Sensitivity, reduction of mass burning rate, and good effect of coating and reduction of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

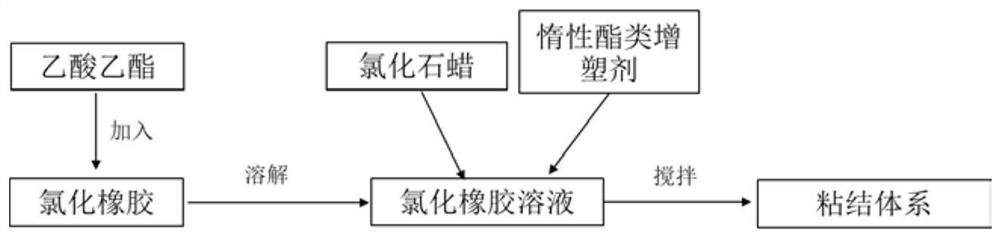

[0030] Such as figure 1 Shown, a kind of preparation method of the bonding system that the present invention discloses improves the safety performance of press-packed PBX explosives, comprises the following steps:

[0031] S1, respectively weigh chlorinated rubber, chlorinated paraffin and inert ester plasticizer according to the following mass percentage formula;

[0032] Chlorinated rubber 20%~40%

[0033] Chlorinated paraffin 30%~60%

[0034] Inert ester plasticizer 0% to 30%;

[0035] S2, adding chlorinated rubber into the reaction equipment, dissolving it with ethyl acetate to form a chlorinated rubber solution, the mass ratio of chlorinated rubber to ethyl acetate is 1:5-1:10; the reaction equipment is equipment that can be heated;

[0036] S3, adding chlorinated paraffin and inert ester plasticizer into the chlorinated rubber solution, and stirring at 50-70° C. for 10-30 minutes to obtain a bonding system.

Embodiment 1

[0038] Take by weighing 40g chlorinated rubber, 25g chlorinated paraffin-42 and 35g chlorinated paraffin-52 respectively; Add chlorinated rubber in the reaction equipment, dissolve with ethyl acetate to form chlorinated rubber solution, the mixture of chlorinated rubber and ethyl acetate The mass ratio is 1:10; chlorinated paraffin and inert ester plasticizer are added to the chlorinated rubber solution, and stirred at 70°C for 30 minutes to obtain a bonding system.

[0039] The prepared bonding system contains 40% of chlorinated rubber and 60% of chlorinated paraffin.

Embodiment 2

[0041] Take by weighing 20g chlorinated rubber, 50g chlorinated paraffin-70 and 30g DOS respectively; Add chlorinated rubber in the reaction equipment, dissolve with ethyl acetate to form chlorinated rubber solution, the mass ratio of chlorinated rubber and ethyl acetate is 1 : 5; chlorinated paraffin and inert ester plasticizer were added to the chlorinated rubber solution, and stirred for 10 min at 50° C. to obtain a bonding system.

[0042] The prepared adhesive system contains 20% of chlorinated rubber, 50% of chlorinated paraffin and 30% of inert ester plasticizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com