Heating device of injection molding machine

A technology for an injection molding machine and a heating device, which is applied to the field of heating devices, can solve the problems of temperature control response decline, controllability decline, difficulty in adding a cooling structure heating function and cooling function, etc., and achieves response decline suppression and controllability The effect of drop suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

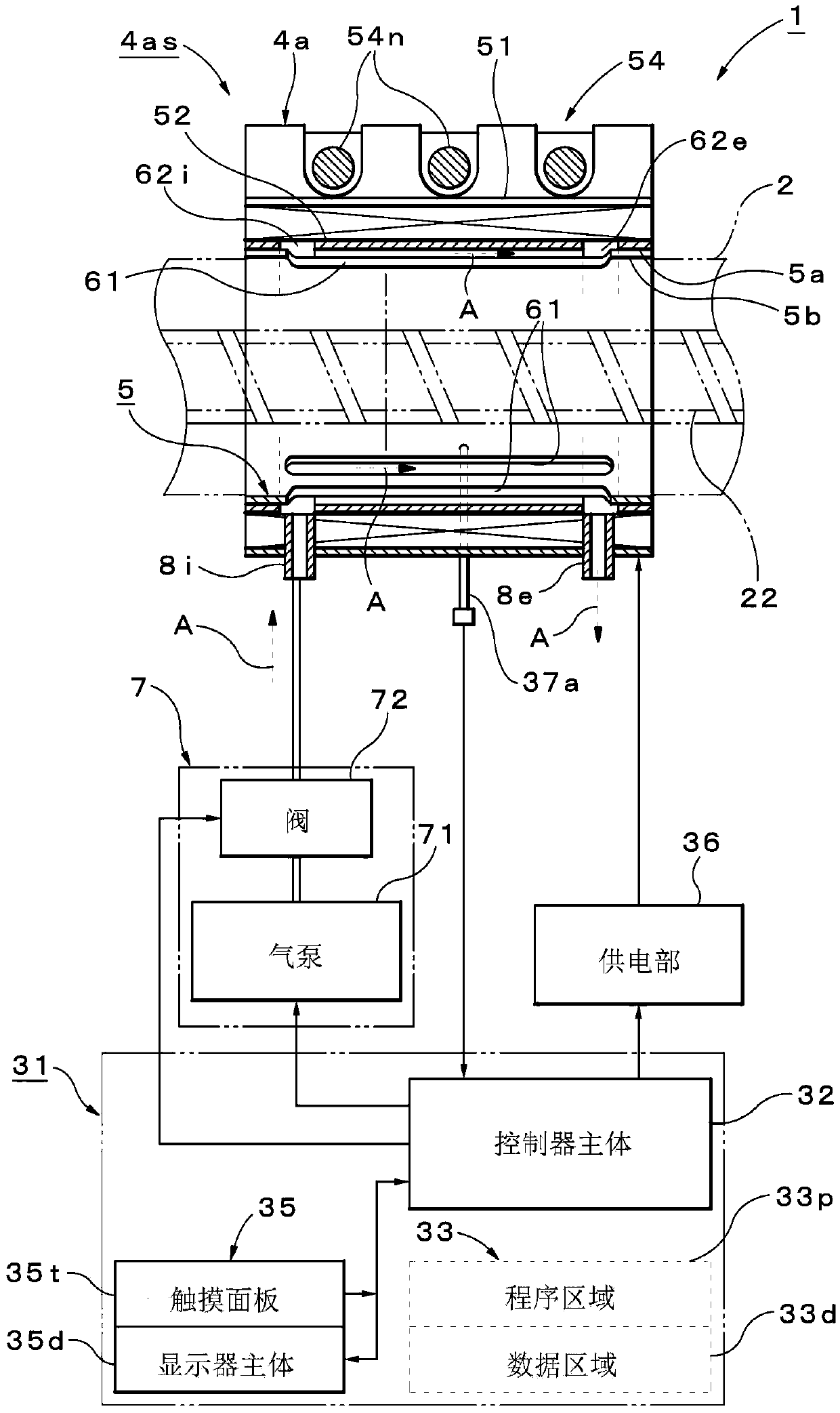

[0034] Next, preferred embodiments of the present invention will be listed and described in detail based on the drawings. In addition, the drawings do not limit the present invention, but are for facilitating understanding of the present invention. In addition, in order to avoid ambiguity of the invention, detailed descriptions of known parts are omitted here. .

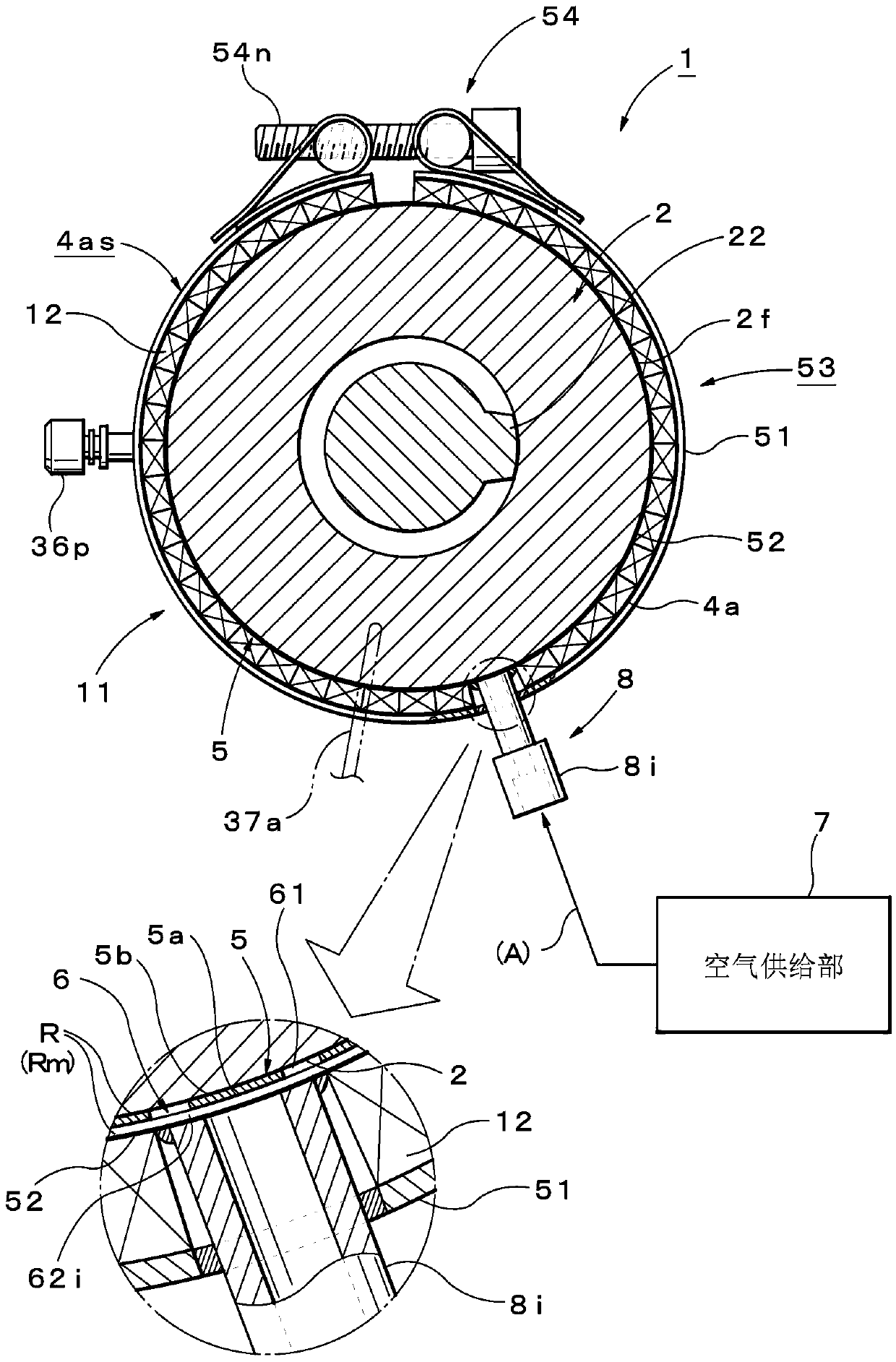

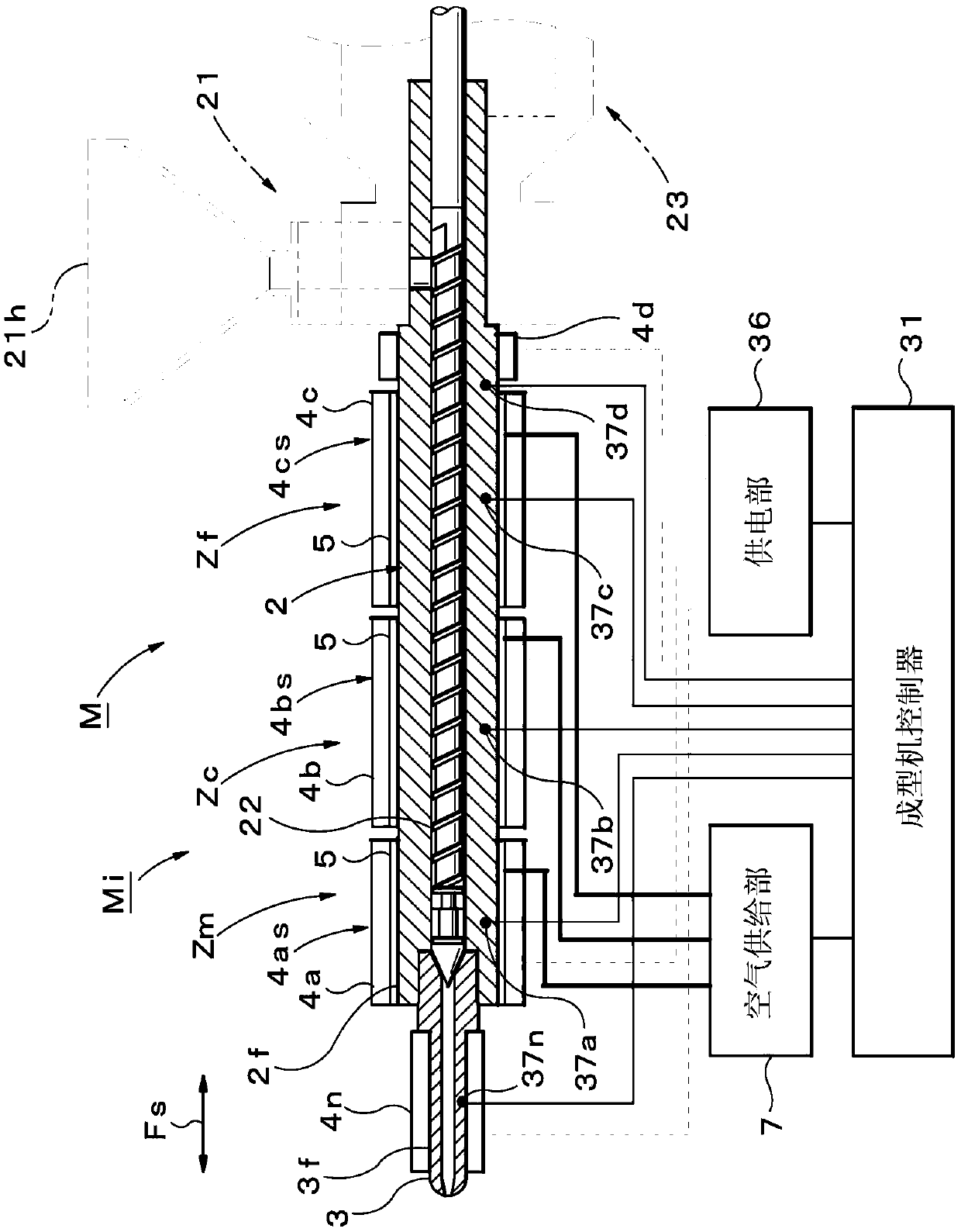

[0035] First, refer to Figure 1 to Figure 7 , the structure of the heating device 1 of the injection molding machine M of this embodiment will be described.

[0036] exist figure 2 Here, Mi is an injection device, and the injection molding machine M is composed of the injection device Mi and a mold clamping device not shown. The injection device Mi has a heating cylinder 2 having an injection nozzle 3 at the front end, and the rear end of the heating cylinder 2 is combined with a material supply part 21 having a function for supplying molding to the inside of the heating cylinder 2. Material funnel 21h. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com