Synchronous system of injection molding machine and oil circuit control method thereof

A synchronous system and injection molding machine technology, applied in the field of hydraulic transmission, can solve the problems of high production cost, inability to meet various working pressures, and time-consuming problems, so as to improve the clamping force, avoid unqualified products, and reduce time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

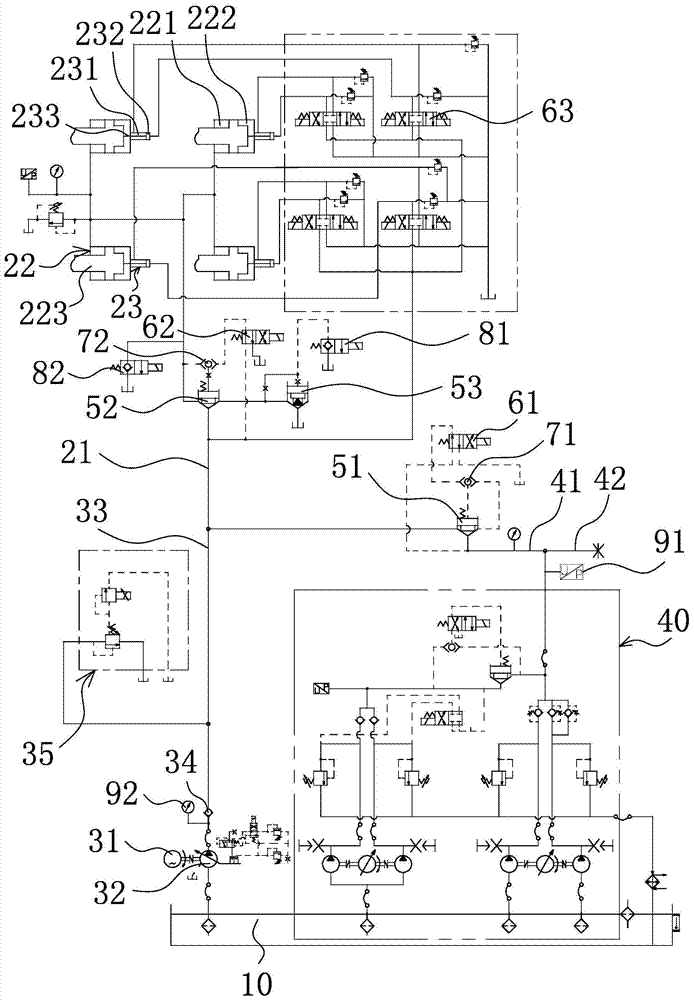

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0032] Such as figure 1 As shown, the injection molding machine synchronization system includes:

[0033] Oil tank 10, used for storing oil;

[0034] The working unit has a working oil circuit 21 for delivering oil;

[0035] The main unit 40 has a first oil passage 41 and a second oil passage 42 that communicate with each other and are used to transport oil. The first oil passage 41 is connected to the working oil passage 21, and a device for controlling The first cartridge valve 51 that connects the first oil passage 41 to the working oil passage 21;

[0036] The auxiliary unit has an auxiliary oil passage 33 for delivering oil, and the auxiliary oil passage 33 communicates with the working oil passage 21 , and the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com