A metal thin film pressing and grinding device

A metal film and extension plate technology, which is applied in the field of metal film pressing and grinding devices, grinding fixtures, and metal film edge grinding devices, can solve the problem of the difficulty in clamping flexible films without deformation and the difficulty in ensuring the consistency of film thickness. Difficult to solve problems such as depressions and uplifts, to achieve the effect of flexible adjustment up and down, strong practicability, and avoid scratches and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing:

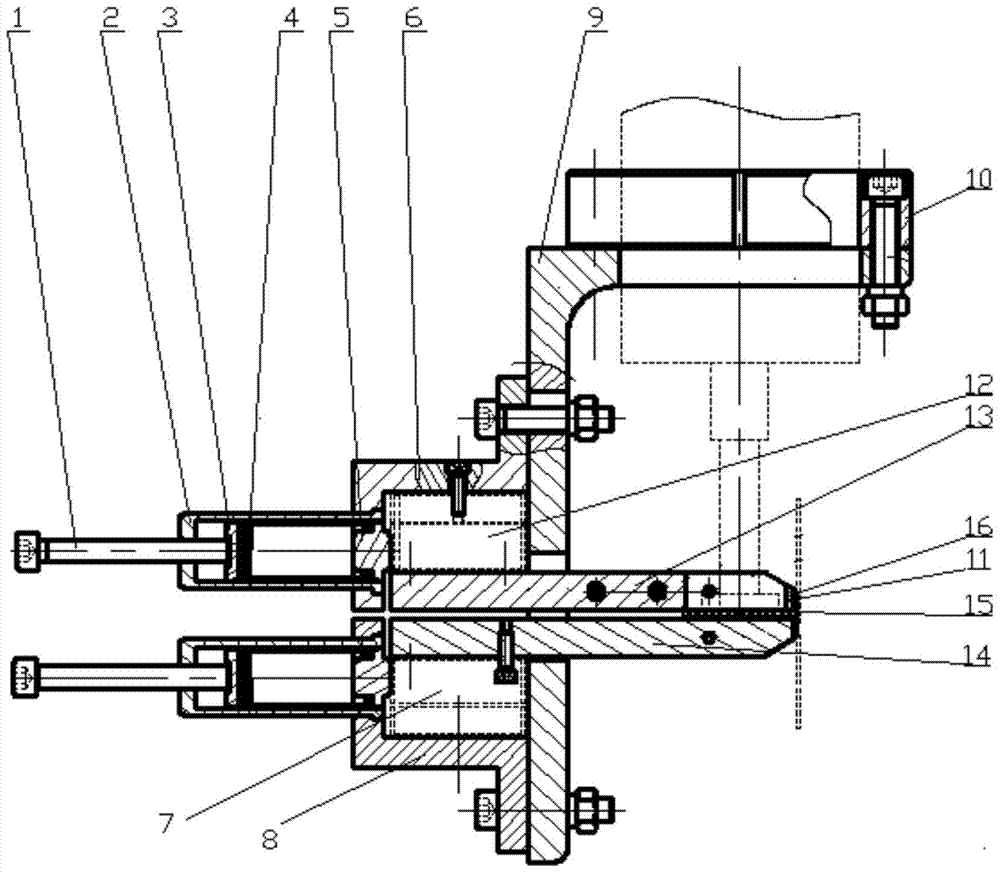

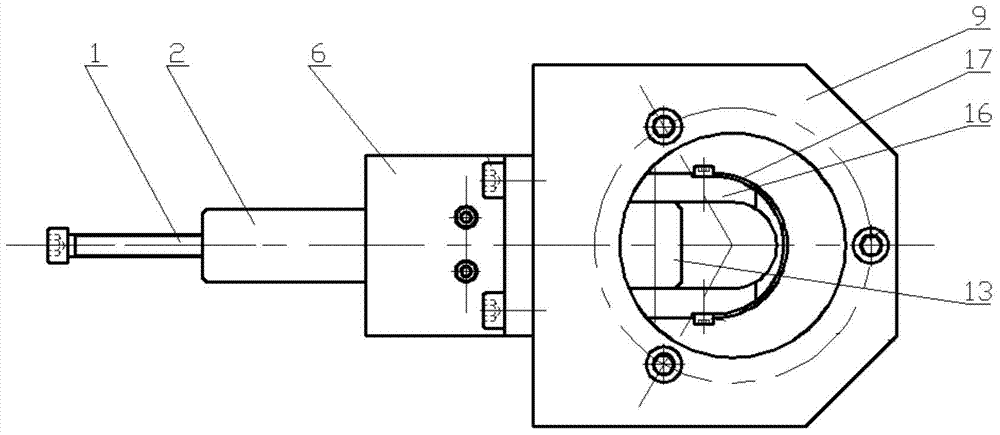

[0038] Provide a metal thin film pressing and grinding device, the device includes a coupling sleeve 10, two spring barrel assemblies, an inverted L-shaped plate 9, an upper sliding table connecting plate 6, a lower sliding table connecting plate 8, an upper sliding table 12, and a lower sliding table 7 , the upper extension 13 and the lower extension plate 14;

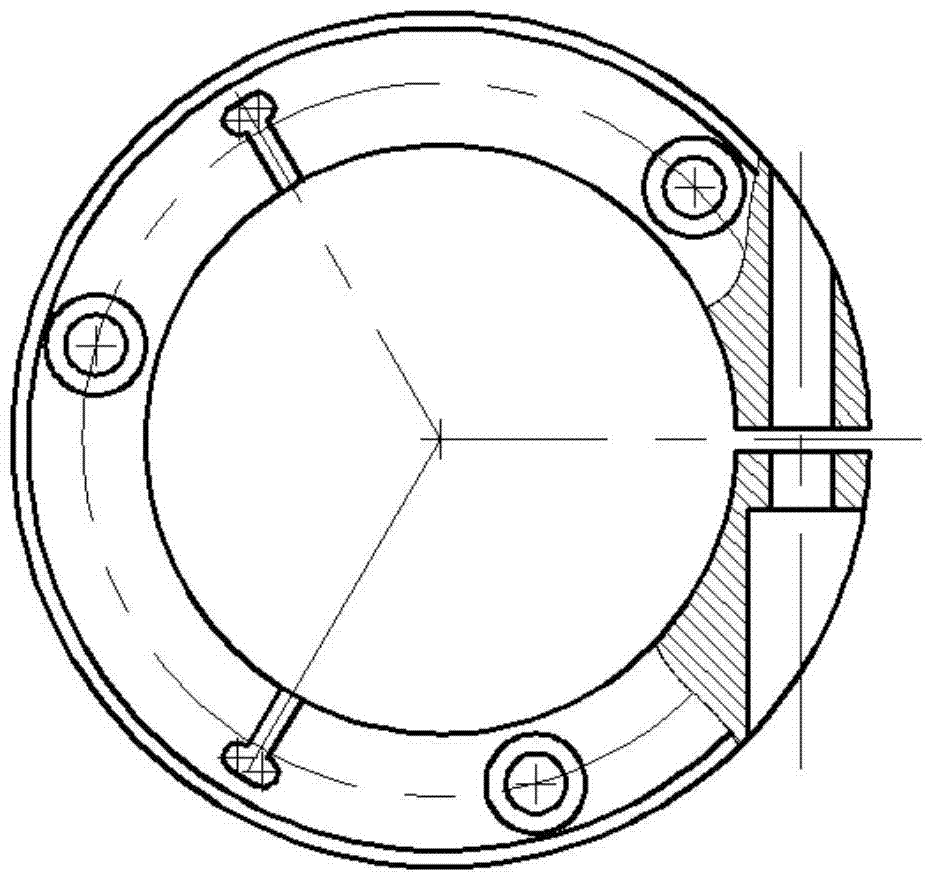

[0039] The coupling sleeve 10 is an annular flange with a notch, which can be placed on the main shaft of the processing machine tool, and the notch can be locked by screws to produce a small amount of elastic deformation and fasten the main shaft. It is integrated; the uniformly distributed countersunk holes are used to realize the connection with other additional devices, which has the advantages of high connection strength, flexible disassembly and adjustment, strong applicability, and compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com