Controllable Laser Processing Device Based on Wavefront Modulation

A technology of wavefront modulation and laser processing, which is applied in the direction of manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve the problems of low safety assurance level, lack of laser safety control measures for laser processing devices, and low intelligence, and achieve The effect of improving laser processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

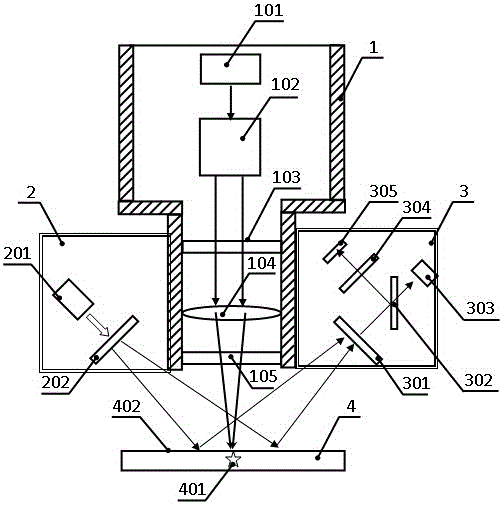

[0014] Such as figure 1 As shown, a controllable laser processing device based on wavefront modulation includes: a laser processing head 1, an irradiation module 2, and a photoelectric detection and analysis module 3; , a focusing element 104 and a window 105, the power supply part 101 is connected to the laser 102 to provide power energy, and the wavefront modulation element 103, the focusing element 104 and the window 105 are sequentially arranged on the exit optical path of the laser 102, and the window 105 directs the laser The system is separated from the processing area by material exchange; the irradiation module 2 and the photoelectric detection and analysis module 3 are respectively located at different positions on the edge of the laser output machine of the laser processing head, and the output beam of the irradiation module 2 can cover the laser processing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com