Circulating spraying type ultraviolet Fenton oxidation organic waste gas treatment system and method

A technology of organic waste gas and circulating spraying, which is applied in gas treatment, chemical instruments and methods, separation methods, etc. It can solve the problems of incomplete degradation of organic matter, excessive generation of iron sludge, and low cycle efficiency, so as to promote gas-liquid mass transfer Speed, reduced usage, good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

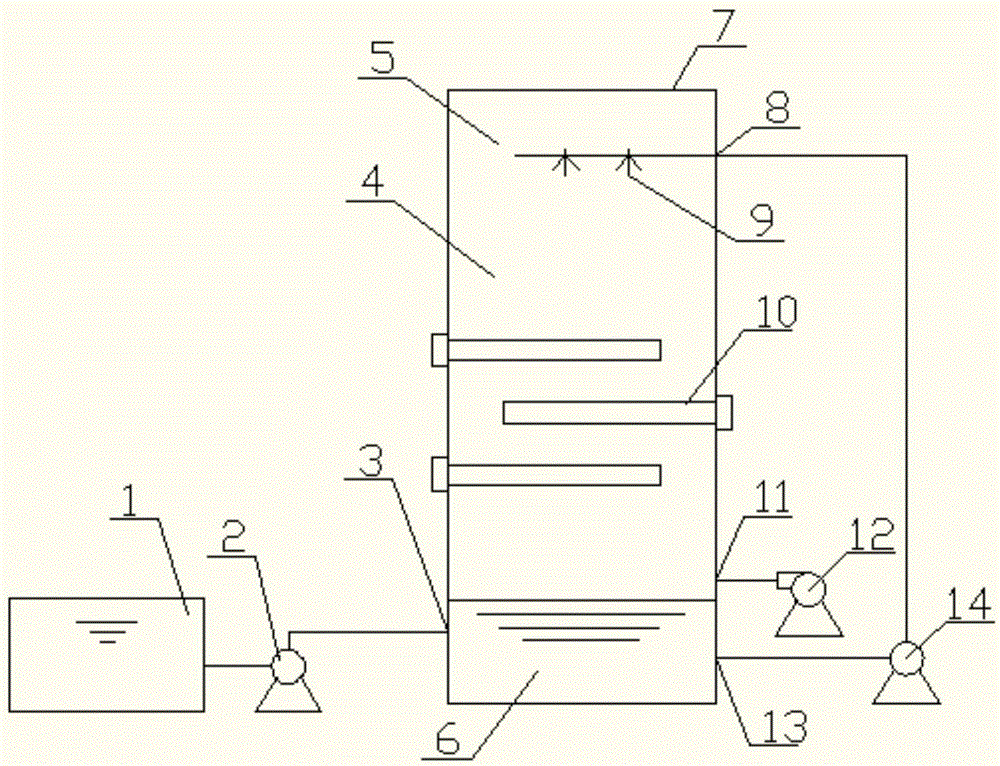

[0028] Circulating spray type UV / Fenton oxidation organic waste gas treatment system, including spray oxidation reaction chamber 4, induced draft fan 12 and hydrogen peroxide dosing device 1, the top of the spray oxidation reaction chamber 4 is provided with an exhaust port 7, The lower part is provided with hydrogen peroxide inlet 3, air inlet 11 and Fenton reagent outlet 13 respectively, and the upper part is provided with Fenton reagent inlet 8; Described induced draft fan 12 is connected with described air inlet 11, and described hydrogen peroxide dosing device 1 Be connected with described hydrogen peroxide inlet 3 by pressure pump 2; Described Fenton reagent outlet 13 is connected with described Fenton reagent inlet 8 by circulation pump 14; Described spray oxidation reaction chamber 4 inner cavity is filled with Fenton reagent 6. A spray device 5 is arranged above the inner cavity of the spray oxidation reaction chamber 4, and the spray device 5 is connected to the Fento...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com