Dried influenza vaccine preparation and method for producing dried influenza vaccine preparation

A technology for influenza vaccine and manufacturing method, applied in biochemical equipment and methods, antiviral agents, freeze-dried delivery, etc., can solve the problem that the dried influenza vaccine preparation is not on the market, and achieve the effect of easy circulation and preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

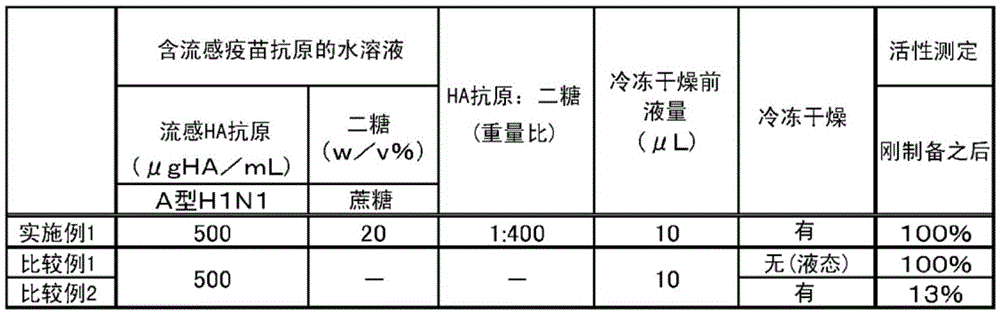

[0054] (freeze-dried influenza HA vaccine preparation)

[0055] Sucrose (manufactured by Wako Pure Chemical Industries, Ltd.) listed in Table 1 was added to influenza HA antigen (type A H1N1: A / California / 07 / 2009, manufactured by Osaka University Institute of Microbial Diseases), and PBS with the following composition was added (Phosphate-buffered sodium chloride solution), an aqueous solution containing influenza vaccine antigen was prepared in such a way that it became 20w / v% sucrose, 500 μg HA / mL influenza HA antigen (400 parts by weight of sucrose relative to 1 part by weight of influenza HA antigen). 10 μL of the obtained aqueous solution containing influenza vaccine antigen was dispensed into a 1.5 mL centrifuge tube (safe-lock tube) (manufactured by Eppendorf), and freeze-dried.

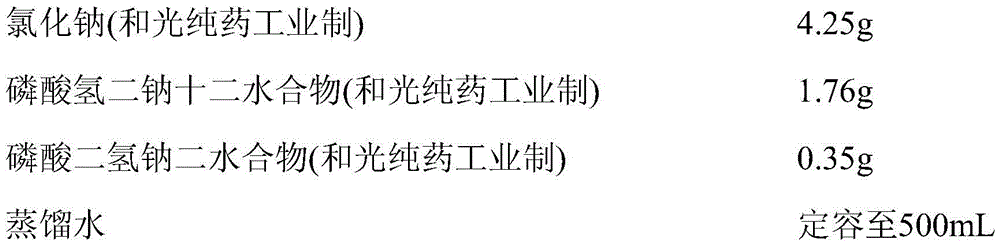

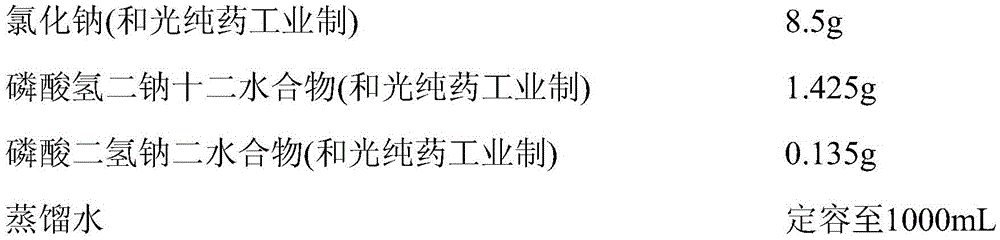

[0056] PBS for preparation

[0057]

Embodiment 2~17

[0076] (freeze-dried influenza HA vaccine preparation)

[0077] A freeze-dried influenza HA vaccine preparation was obtained in the same manner as in Example 1, except that the type and content of the disaccharide, or the liquid volume before freeze-drying were changed as shown in Table 2.

Embodiment 18~21

[0085] (freeze-dried influenza HA vaccine preparation)

[0086] A freeze-dried influenza HA vaccine preparation was obtained in the same manner as in Example 1 except that the content of the influenza HA antigen was changed as shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com