Rigid-flex board and mobile terminal

A soft-rigid combination board and hard layer technology, applied in the structural connection of printed circuits, printed circuit components, electrical components, etc., can solve the problems of improper connection, inability to connect, separation of circuit layer and hard layer, etc. The effect of ensuring the conduction connection and enhancing the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

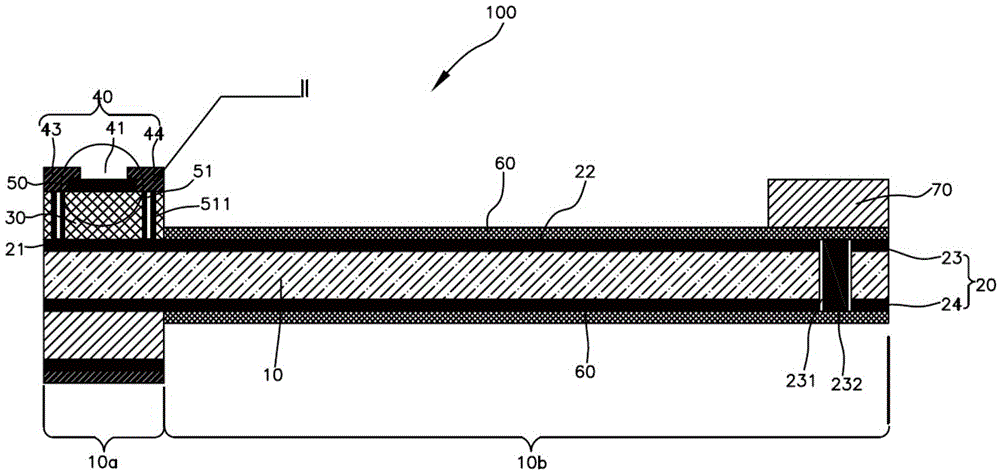

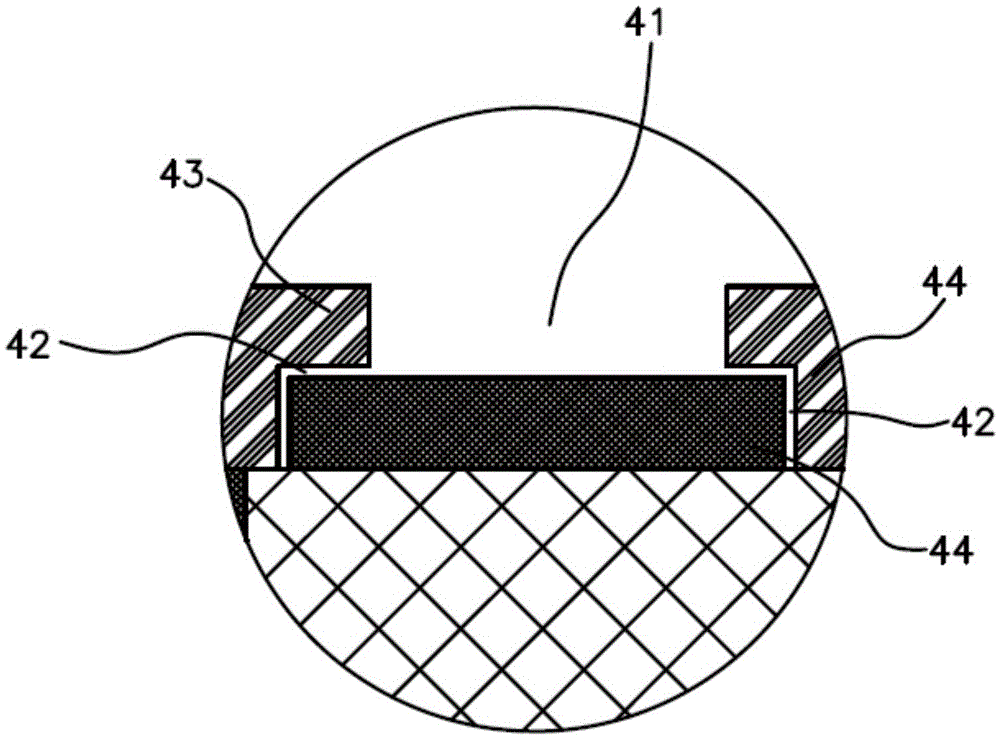

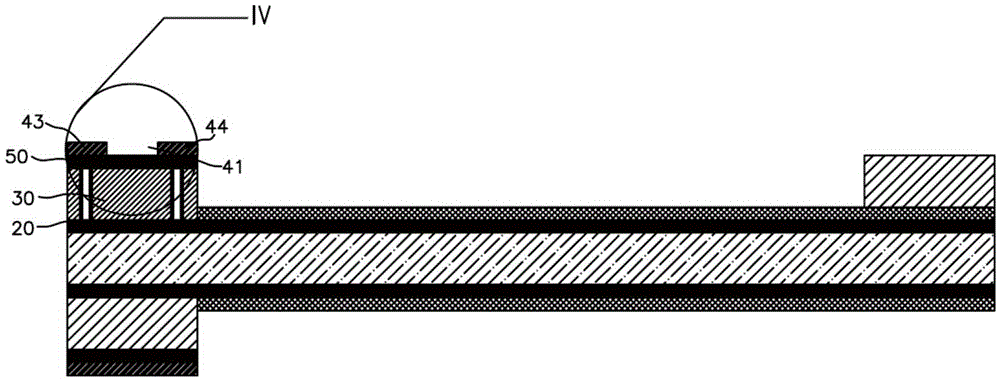

[0021] Please also refer to Figure 1 to Figure 2 , a rigid-flex board 100 provided by an embodiment of the present invention, the rigid-flex board 100 includes a flexible substrate layer 10 , a copper foil layer 20 , a hard layer 30 , a solder resist ink layer 40 and a circuit layer 50 . The copper foil layer 20 is stacked on the flexible substrate layer 10 , and the hard layer 30 is disposed on a side of the copper foil layer 20 away from the flexible substrate layer 10 . The solder resist ink layer 40 is arranged on the hard layer 30, and an empty window 41 is opened on the solder resist ink layer 40 to expose part of the hard layer 30. The empty window 41 covers the solder resist The ink layer 40 is divided into two parts opposite to each other. The two parts are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com