Analysis and detection method for impurity in lapatinib ditosylate bulk drug

A technology of di-p-toluenesulfonic acid and lapatinib, which is applied in the direction of material separation, analytical materials, measuring devices, etc., can solve the problems that the analysis and detection methods need to be improved, and achieve good separation, good resolution, and strong specificity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

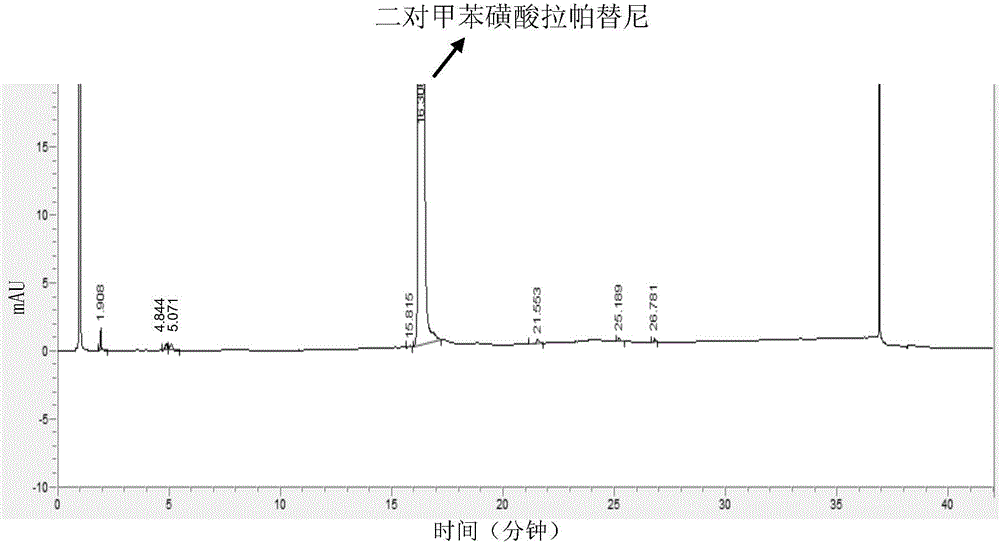

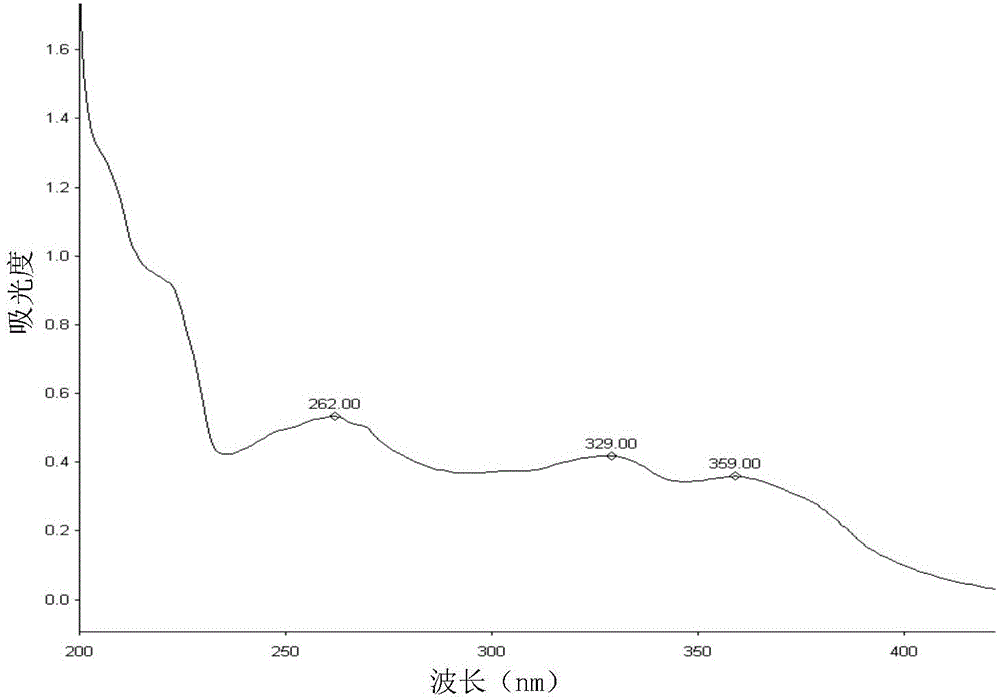

[0041] Embodiment 1: the determination of detection wavelength

[0042] Get an appropriate amount of lapatinib di-p-toluenesulfonate crude drug, adopt acetonitrile-water (volume ratio 4:1) mixed solvent to dissolve and dilute to make the solution that contains about 20 μ g crude drug in every 1ml, in ultraviolet-visible spectrophotometer Full scan at 190nm~400nm, see UV scan figure 1 . Depend on figure 1 It can be seen that the maximum absorption wavelength of lapatinib di-p-toluenesulfonate is 262nm, so 262±2nm is selected as the detection wavelength.

Embodiment 2

[0044] Chromatographic conditions: 100mm×4.6mm, 3μm PhenmonexLunaC 18 Column, with 50mmol / L ammonium acetate buffer solution (take 3.85g ammonium acetate, dissolve in 990ml water, adjust pH to 4.5 with glacial acetic acid, dilute to 1000ml with water) as mobile phase A, use acetonitrile as mobile phase B, detection wavelength 262nm , the column temperature is 40 degrees Celsius, the flow rate is 10ml / min, the injection is 5μl, and the linear gradient elution gradient conditions are as follows.

[0045] time (min)

Mobile Phase A(%V / V)

Mobile Phase B(%V / V)

0

60

40

8

42

58

19

10

90

35

10

90

35.1

60

40

42

60

40

[0046] Experimental steps:

[0047] 1. Take an appropriate amount of lapatinib di-p-toluenesulfonate, dissolve it with acetonitrile-water (volume ratio 4:1) mixture and quantitatively dilute it with acetonitrile-water (volume ratio 4:1) to make 1ml containing...

Embodiment 3

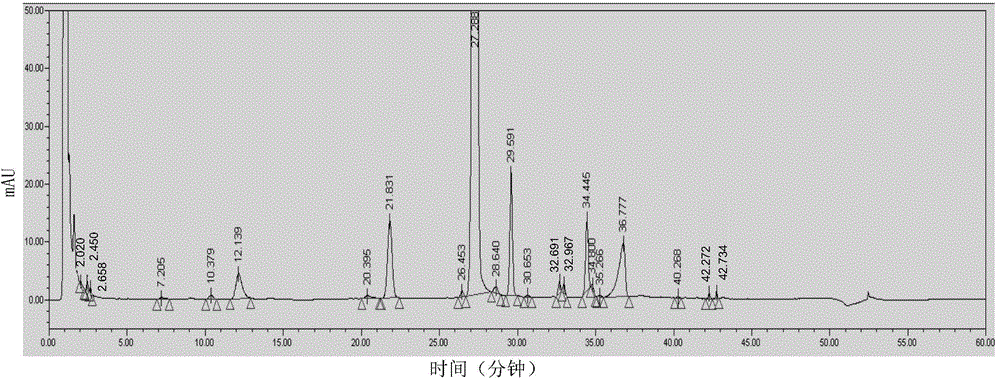

[0051] In order to improve the detection limit of impurities and the resolution between impurities, the chromatographic conditions are as follows:

[0052] Using 100mm×4.6mm, 3μm PhenmonexLunaC 18 Column, with 50mmol / L ammonium acetate buffer solution (take 3.85g ammonium acetate, dissolve in 990ml water, adjust pH to 4.5 with glacial acetic acid, dilute to 1000ml with water) as mobile phase A, use acetonitrile as mobile phase B, detection wavelength 262nm , the column temperature is 40 degrees Celsius, the flow rate is 1.0ml / min, the injection volume is 15μl, and the linear gradient elution gradient conditions are shown in the table below.

[0053] time (minutes)

Mobile phase A(%)

Mobile phase B(%)

0

65

35

13

65

35

[0054] 33

42

58

43

10

90

48

10

90

50

65

35

60

65

35

[0055] Experimental steps:

[0056] 1. Take an appropriate amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com