Laser measurement device for simply measuring mechanical vibration amplitude

A technology of mechanical vibration and laser measurement, which is used in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., to achieve the effects of simple use, high efficiency, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The text invention will be further described below in conjunction with specific embodiments.

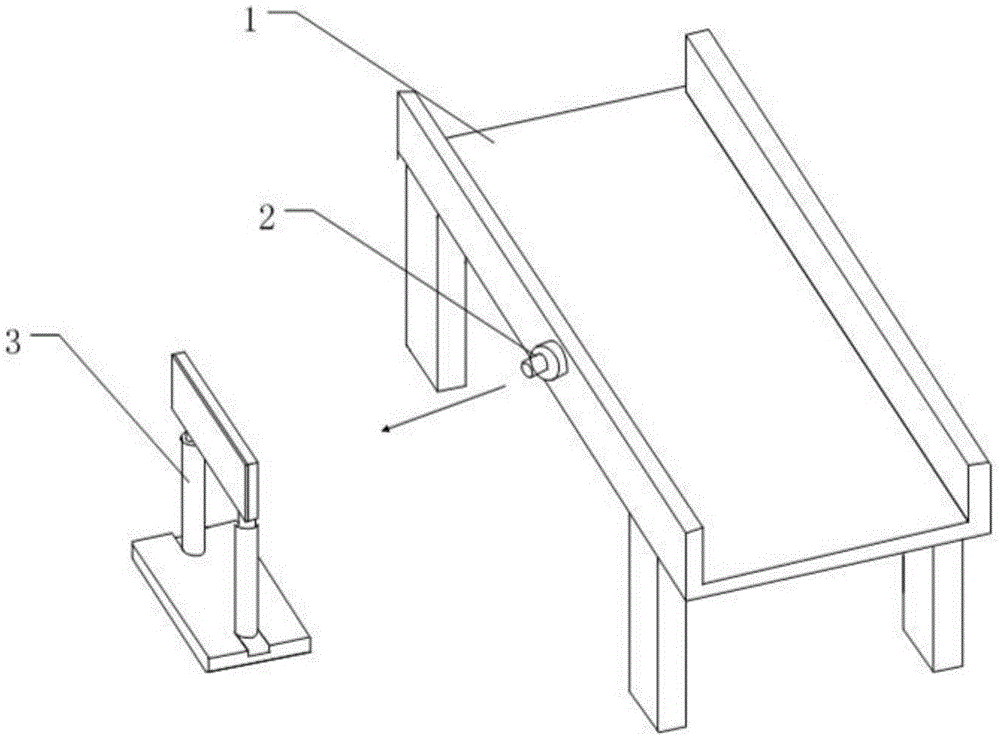

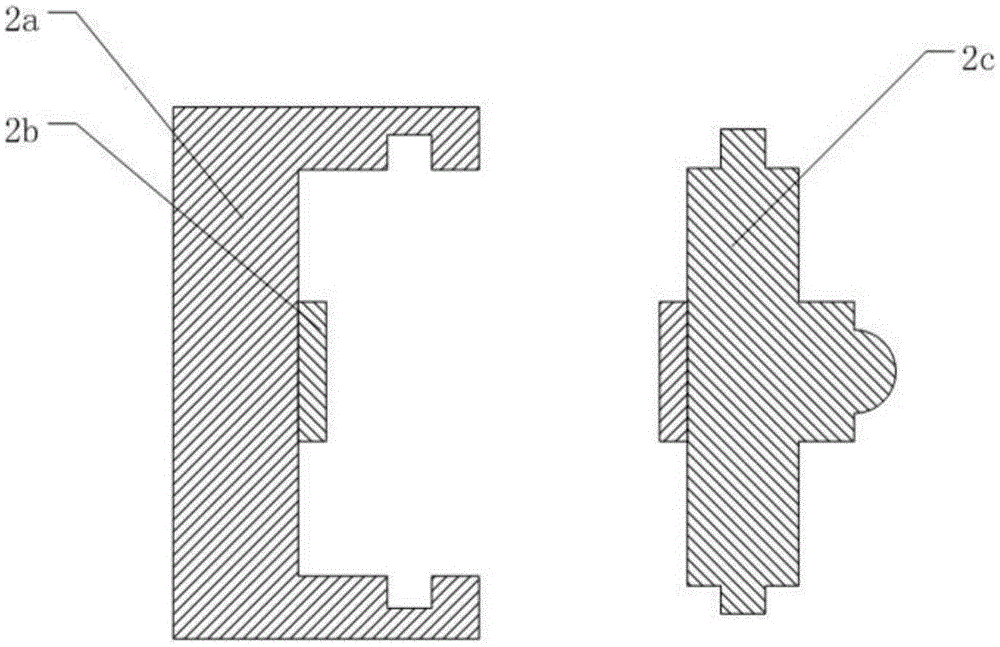

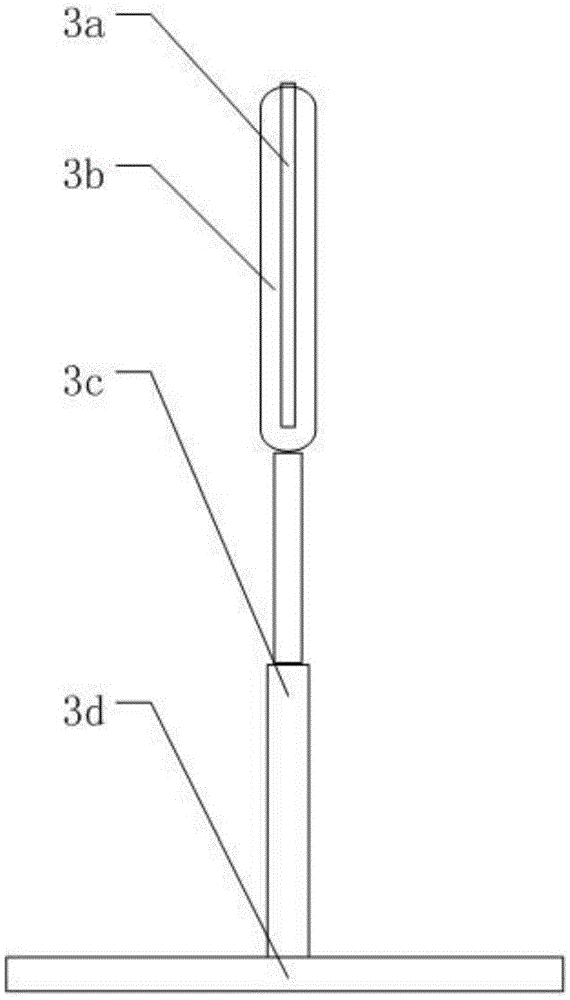

[0020] Such as figure 1 As shown, the laser assembly 2 and the light spot receiving assembly 3; the laser assembly 2 is fixedly installed on the vibration machine body 1, the laser assembly 2 includes a laser emitter holder 2a and a laser emitter 2c, and the laser emitter 2c is stuck on the laser emitter On the card holder 2a; the spot receiving component 3 includes a coordinate paper slot 3a, a receiving plate 3b, a bracket 3c, a coordinate paper 3e and a ground fixing device 3d, and a coordinate paper slot 3a is arranged inside the receiving plate 3b, and the coordinate paper 3e is put into the receiving plate In the coordinate paper slot 3a in 3b, the ground fixing device 3d is connected with the bracket 3c, and the receiving plate 3b is connected with the bracket 3c. There is a positioning and fixing magnet 2b in the center of the laser transmitter deck 2a, and the bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com