Simulated test platform for radial winding deformation of transformer

A technology of transformer winding and radial deformation, applied in instruments, measuring electrical variables, measuring devices, etc., can solve problems such as troublesome, difficult to simulate easily, not flexible enough, and not accurate enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

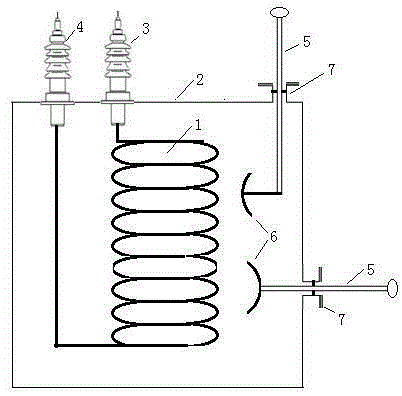

[0019] Such as figure 2 , a simulation test platform for transformer winding deformation, which consists of 110kV winding (1), transformer oil tank (2), 110kV high voltage bushing (3), 10kV low voltage bushing (4), duralumin push rod of a real power transformer (5), iron deformation block (6) and dynamic sealing mechanism (7). Wherein the height of the winding is 1080mm, and the outer diameter is 1150mm; the fuel tank (2) is a square box made of iron. The minimum gap between the winding (1) and the oil tank (2) is 240mm; the dynamic sealing mechanism (7) includes the through flange of the oil tank wall and an O-shaped rubber sealing ring, which can ensure easy control of the push rod (5) extending in or out

[0020] The winding (1) is placed inside the fuel tank (2), and the high-voltage lead wire of the winding (1) is led out of the fuel tank (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com