A manufacturing process for reserved expansion joints and deformation joints of anti-collision guardrails

A technology of anti-collision guardrails and manufacturing technology, which is applied to bridge parts, bridges, buildings, etc. It can solve the problems of wasting materials, reinforcement difficulties, and affecting appearance, etc., and achieves straight deformation joints and expansion joints, easy manufacturing, and easy dismantling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

[0020] A manufacturing process of bridge anti-collision guardrail expansion joints and deformation joints, the steps are:

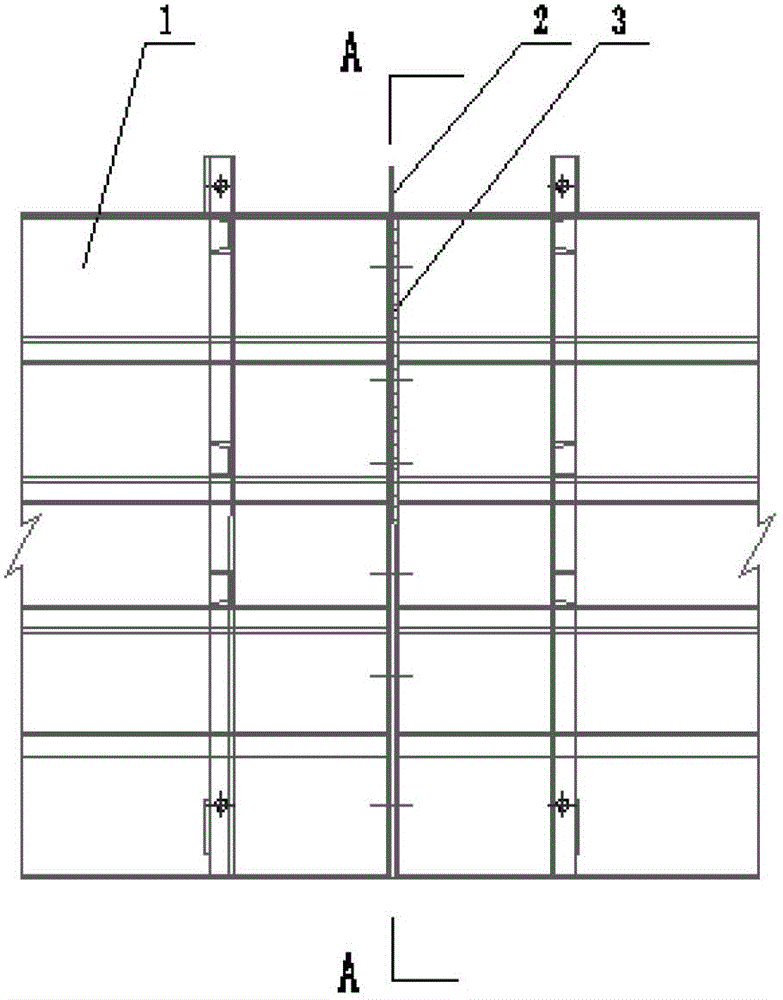

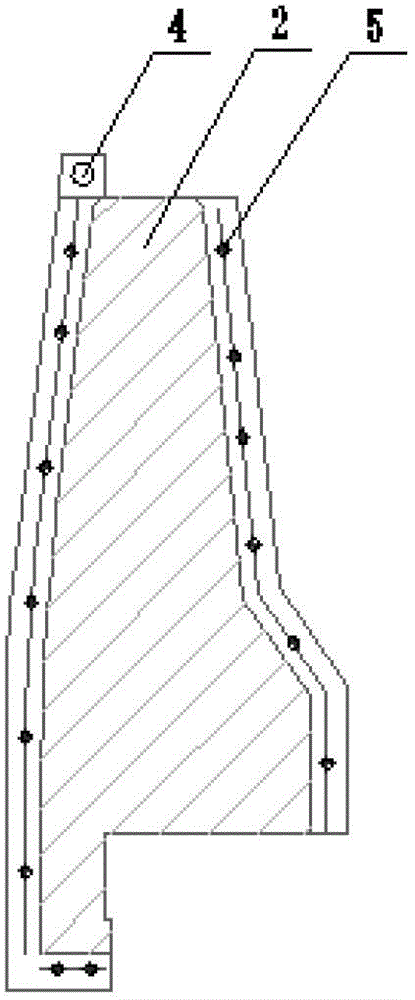

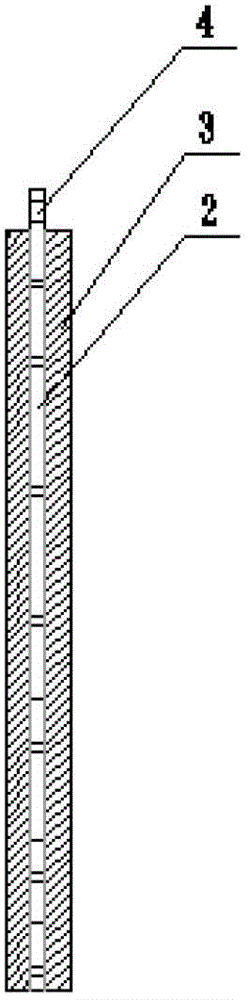

[0021] (1) Process the deformation seam steel plate 2 into the transverse size of the guardrail 6, and bolt holes 5 are uniformly distributed on the outer contour of the deformation seam steel plate, and the bolt holes correspond to the bolt holes made by the guardrail formwork 1. Make a lifting hole 4 for removal at the upper end;

[0022] ⑵According to the width of the deformation seam reserved for the guardrail, select the foam board 3 of appropriate thickness, and also process it into the shape of the guardrail. Before installing the guardrail template, place the two foam boards at the position of the deformation seam in advance, and the middle of the two foam boards Reserve the position according to the thickness of the deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com