Massive concrete pouring method

A large-volume concrete and volume technology, applied in construction, infrastructure engineering and other directions, can solve the problems of small size, no success, and no precedent for grouting construction, and achieve the effects of reducing costs, reducing usage, and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

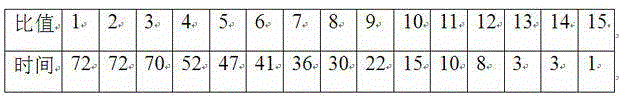

[0026] The pouring method of a kind of large-volume concrete of the present invention is applied in the grouting construction of the secondary grouting pit of the 800MN press main frame. The length of the single block of the secondary grouting pit of the 800MN press main frame is 13.6m, the width is 6.1m, and the total area is 82.96m 2, the floor grouting thickness is 0.3m, and the grouting thickness of the edge and central opening is 0.65m. The calculated grouting volume is about 30m 3 , the two foundations are about 60m 3 , to calculate a certain loss of 5%, a total of 63m of secondary grouting material is required 3 , material density 2200kg / m 3 , the amount of material used is about 138.6 tons, which is super large monomer foundation grouting.

[0027] (A) Formwork: support the formwork around the secondary grouting pit of the main engine of the 800MN press, and install cooling pipes in the area where the thickness reaches 200mm. The inlet and outlet of the cooling pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com