Bridge main cable saddle with self-returning function

A main cable saddle and bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of large vertical force of the main cable, difficult to meet the strength of the middle tower, increase the vertical deflection of the main span under load, etc., and achieve reduction Requirements, save engineering cost, and reduce the effect of later maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

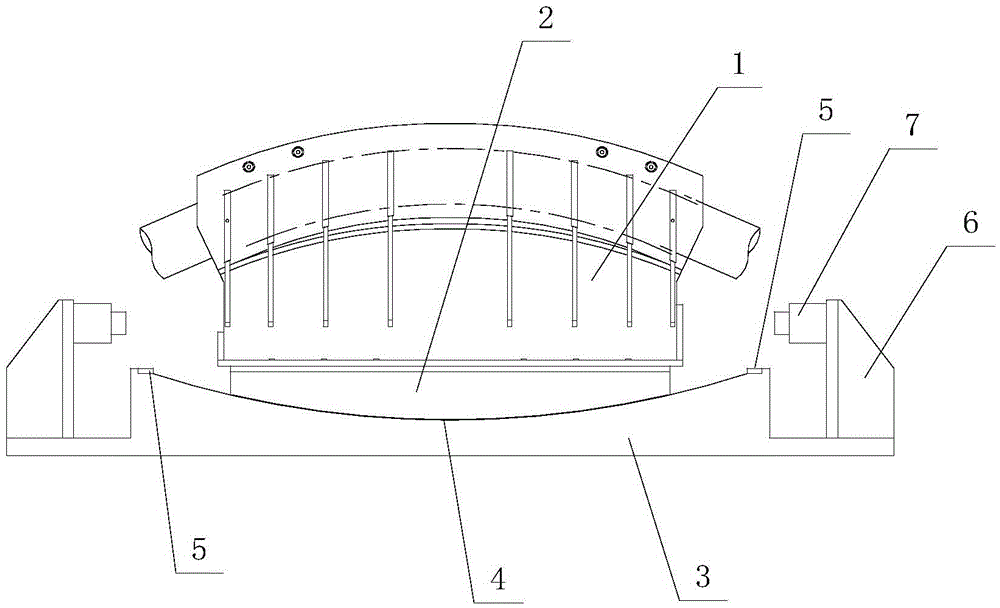

[0022] See Figure 1 to Figure 3 , A bridge main cable saddle with self-recovery function, comprising a base 3 and a saddle body 1. The bottom of the saddle body 1 is detachably connected to a rotating base 2 through a bolt, and the rotating base 2 is in sliding fit with the base 3, and The mating surface 4 of the rotating seat 2 and the base 3 is a concave arc surface.

[0023] Further, a sliding plate made of polytetrafluoroethylene material (not shown in the figure) is arranged on the arc-shaped bottom surface of the rotating seat 2, and a chrome-plated layer (not shown in the figure) is arranged on the top surface of the base 3, and the sliding plate and the chromium-plated layer are formed in cooperation Sliding friction pair. Another structure can also be adopted. The arc-shaped bottom surface of the rotating base 2 is provided with a sliding plate made of PTFE material (not shown in the figure), and an arc-shaped stainless steel layer is provided on the top surface of the...

Embodiment 2

[0028] See Figure 4 The difference between this embodiment and the first embodiment is that the mating surface 4 of the rotating seat 2 and the base 3 is a convex arc surface.

[0029] A convex sliding pair is arranged under the saddle body 1, and the saddle is rotating when sliding, and the height of the center of the saddle becomes lower. As the saddle rotates, the height of the sliding side becomes lower, and the height of the cable tension side increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com