Boron silane modified silicon resin, addition type resin composition and application

A silica gel composition and modified silica technology, applied in the field of materials, can solve the problems of poor filler dispersion, poor wetting of substrates or fillers, poor system compatibility, etc. performance, improving long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

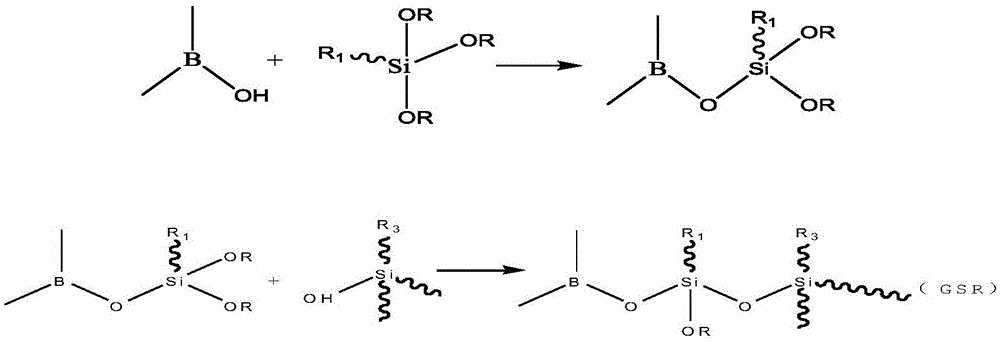

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 addition type silica gel composition

[0046]

[0047] Among them, the refractive index of the phenyl vinyl silicone resin is 1.53%, and the vinyl content is 5%. The refractive index of the phenyl hydrogen-containing crosslinking agent is 1.54, and the hydrogen content is 0.3%. Phenylvinyl silicone oil has a refractive index of 1.53 and a vinyl content of 1%.

Embodiment 2

[0048] Embodiment 2 addition type silica gel composition

[0049]

[0050] Among them, the refractive index of the phenyl vinyl silicone resin is 1.53%, and the vinyl content is 5%. The refractive index of the phenyl hydrogen-containing crosslinking agent is 1.54, and the hydrogen content is 0.3%. Phenylvinyl silicone oil has a refractive index of 1.53 and a vinyl content of 1%.

Embodiment 3

[0051] Embodiment 3 addition type silica gel composition

[0052]

[0053]

[0054] Among them, the refractive index of the phenyl vinyl silicone resin is 1.53%, and the vinyl content is 5%. The refractive index of the phenyl hydrogen-containing crosslinking agent is 1.54, and the hydrogen content is 0.3%. Phenylvinyl silicone oil has a refractive index of 1.53 and a vinyl content of 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com