Method for producing aromatic polycarbonate

A technology of polycarbonate and a manufacturing method, which is applied in the manufacturing field of aromatic polycarbonate, can solve problems such as device corrosion, fluctuation, and difficulty in separating sodium chloride and dichloromethane, and achieves the effect of easy pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

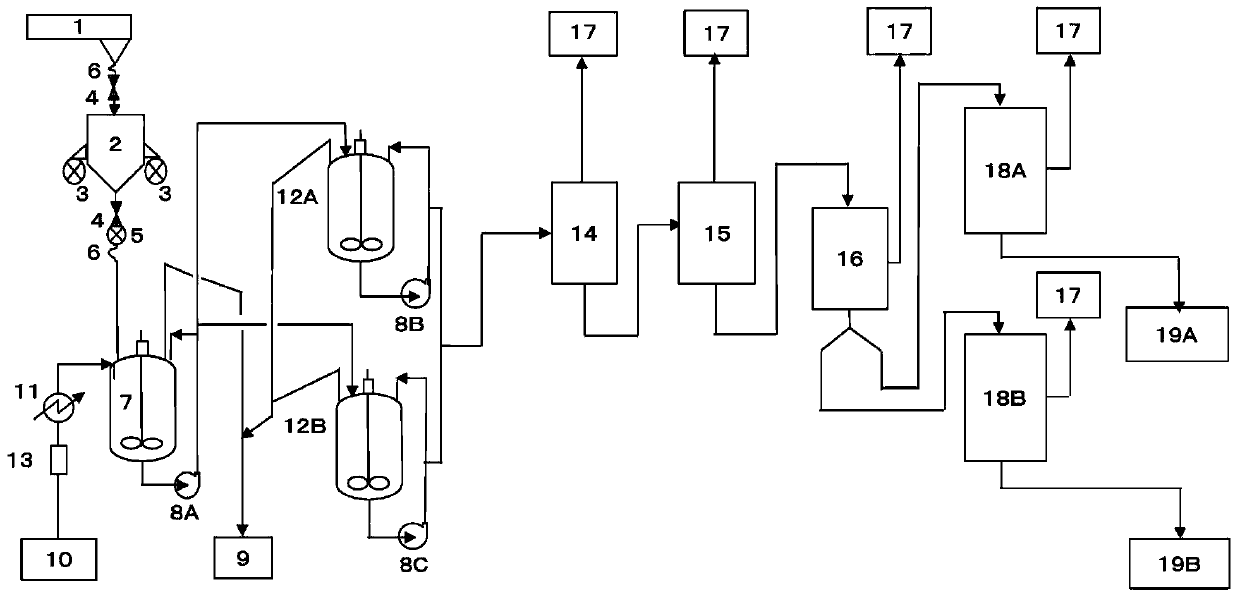

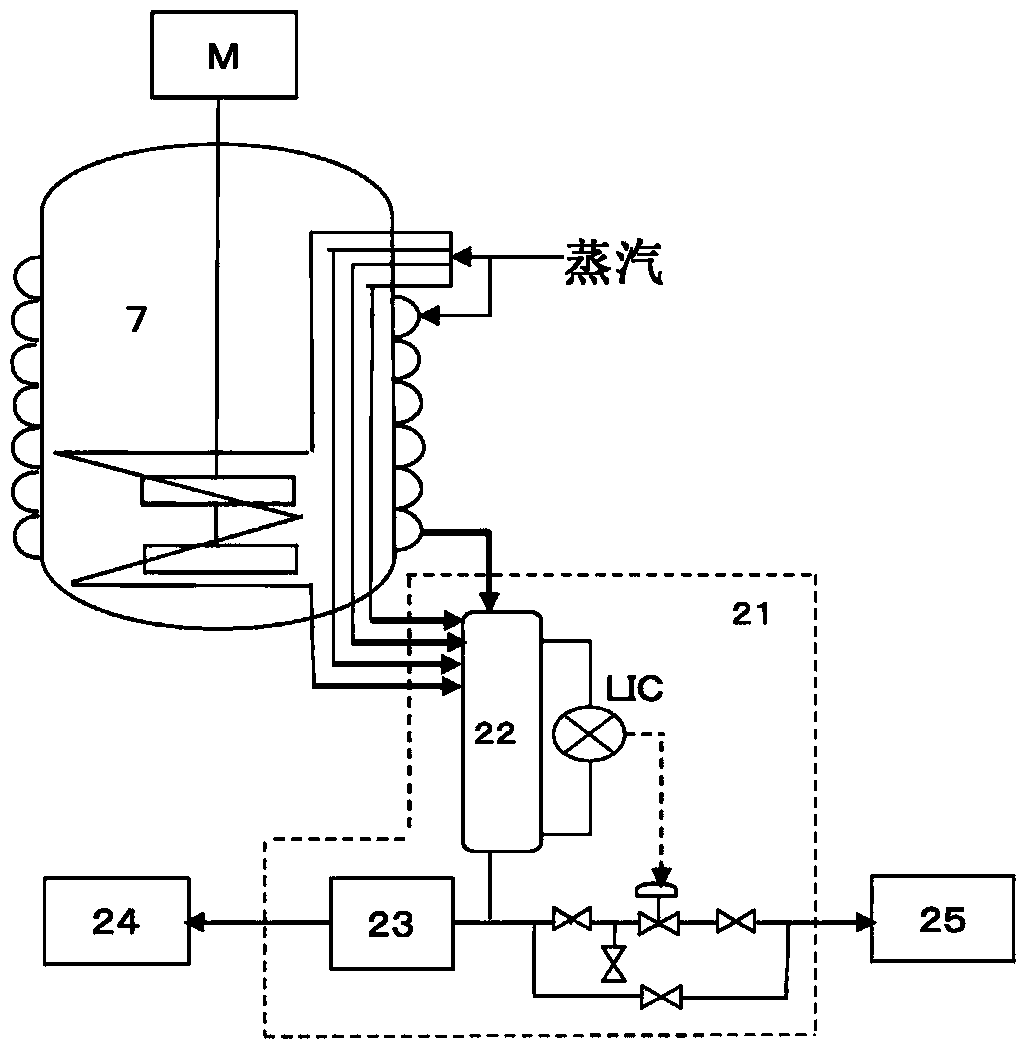

[0210] use figure 1 Fabrication setup shown. More specifically, a mixing tank 7 with a diameter of 3.8 m and an internal volume of 80 m was used. 3 A vertical mixing tank with 2-stage impeller blades. To the upper part of the mixing tank 7, a pipe nozzle for feeding an aromatic dihydroxy compound with a flange part having an inner diameter of 400 mm was connected. exist figure 2 The stand-alone gantry 20 setup shown has an internal capacity of 90m 3 The metering tank 2 and load cell 3. The independent stand 20 is built on an independent base, and is provided with flexible electrical wiring, cables for instruments, and piping. The windshield stand (not shown) is a building built on a base manufactured independently from the base of the stand-alone stand 20 on the outside of the stand-alone stand 20, and supports such as piping are attached thereto. Metering tank 2 is connected with a displacement of 150Nm 3 / h is an exhaust control valve used to control the internal pre...

Embodiment 2

[0228] An aromatic polycarbonate was produced in the same manner as in Example 1, except that the large supply amount of DPC was changed to 21.3 tons (86.2% by mass) and the small supply amount was changed to 3.41 tons. The results are listed in Table 1.

Embodiment 3

[0230] The capacity in use is 90m 3 An aromatic polycarbonate was produced in the same manner as in Example 1, except that the metering tank was not provided on an independent stand but on a non-independent stand, that is, a stand sharing a base with the mixing tank. The indicated value of the load cell 3 is affected by external vibration or wind, and there is an error in the amount of BPA supplied to the mixing tank 7 . Therefore, the feeding molar ratio of DPC and BPA deviates, and compared with Example 1, the adjustment range of the pressure of the main polymerizers 18A and 18B is slightly larger, and it is found that the MI and OH% of the produced aromatic polycarbonate are relatively large. small changes. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com