Water turbine pole iron-core press-fit method

A technology for pole cores and water turbines, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of uneven force on pole core punching pieces, affecting the quality of pole cores, and easy arching of pole cores, etc. The effect of simple pressure control, convenient operation and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Such as figure 2 As shown, the hydraulic turbine magnetic pole core press-fitting method of the present invention sequentially includes a positioning step, a pressurizing and maintaining pressure step, and a welding step.

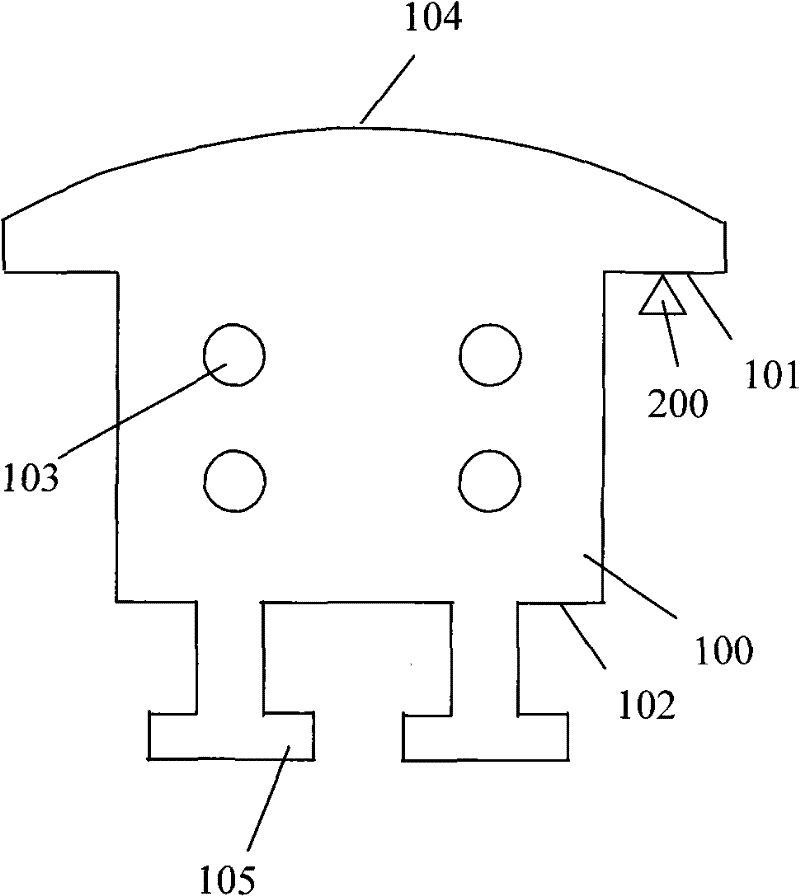

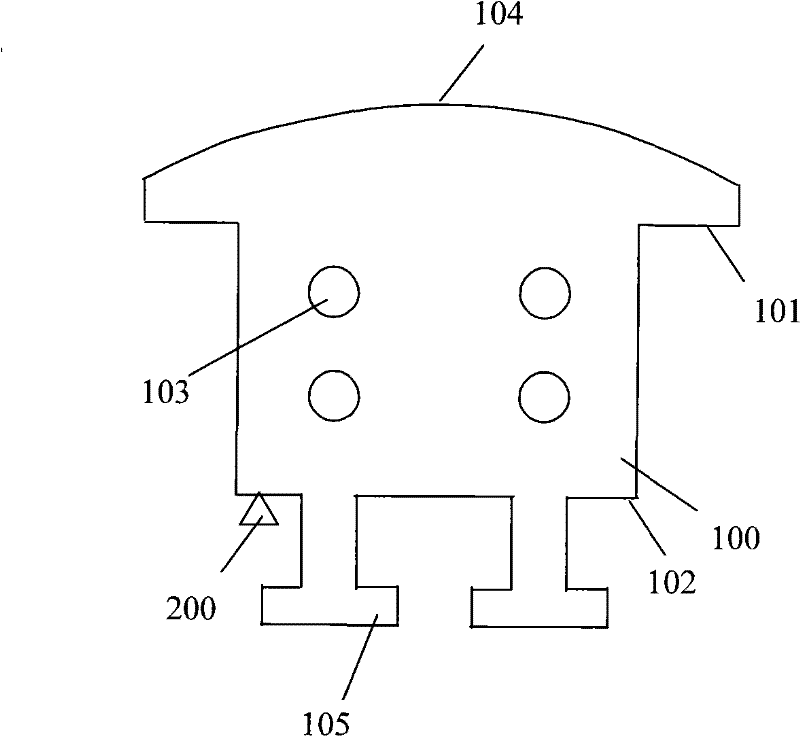

[0020] which, combined with image 3 As shown, the positioning step is to use the positioning track 200 to position the pole core punching pieces at the two lower shoulder blades 102 of the pole core 100 .

[0021] combine Figure 4 As shown, the steps of pressurizing and maintaining pressure are to use hydraulic device 300 to pressurize and maintain the pressure on the pole core 100 at the two upper shoulder blades and the double T tails. In the present invention, the pressure of the magnetic pole core of the water turbine is 300kN, and it is required to be pressed in sections. If the tightening force is large with the screw rod, it will take a long time, so the hydraulic device 300 is used to pressurize and maintain the pressure. The hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com