Preparation of a metal-organic framework material used for natural-gas purification

A technology of organic frameworks and framework materials, applied in the direction of 2/12 organic compounds without C-metal bonds, gas fuels, zinc organic compounds, etc., can solve problems such as waste of cost and difficulty in separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

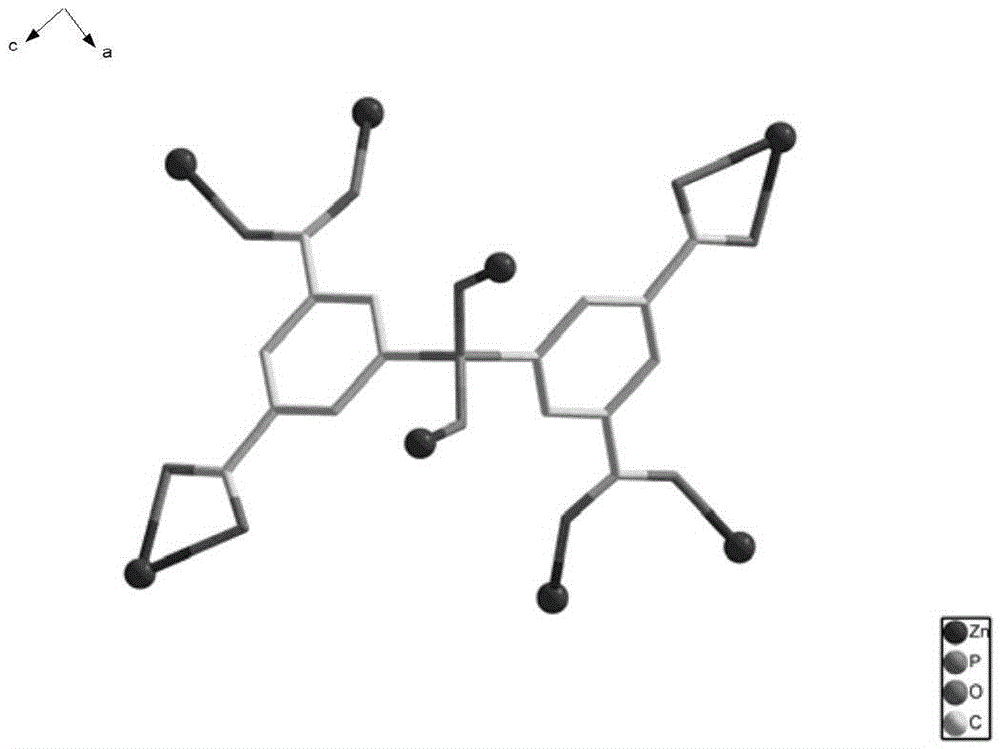

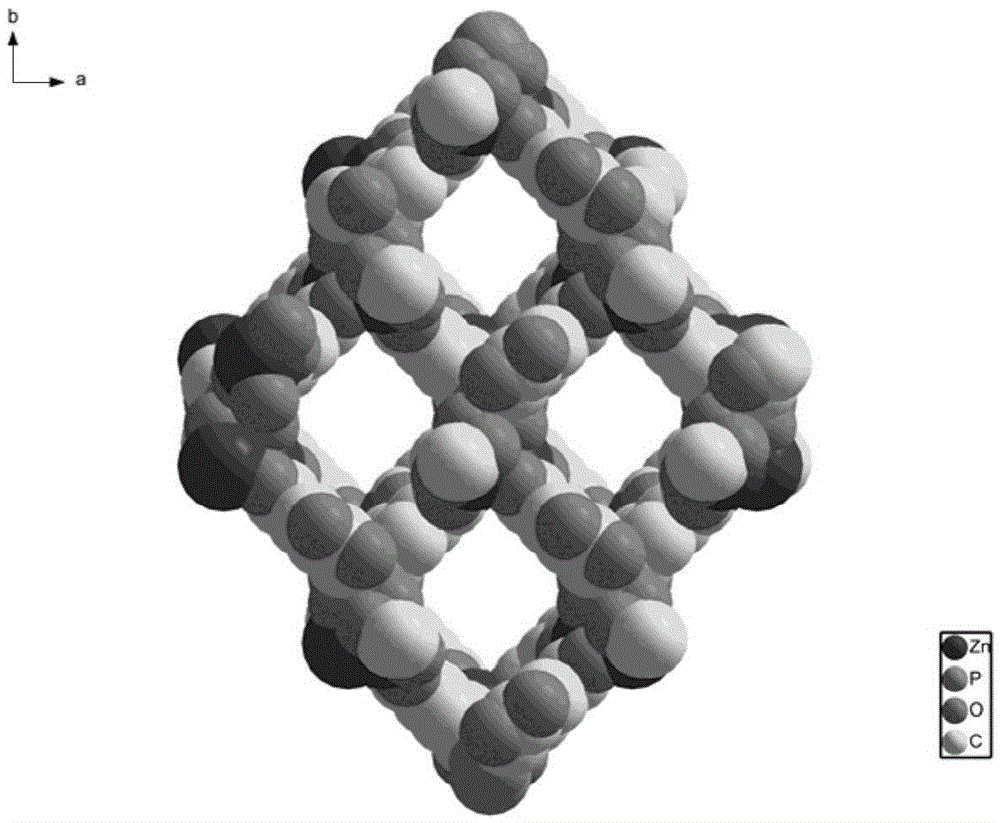

[0010] Embodiment 1: the preparation method of zinc metal-organic framework material

[0011] Add bis(3,5-dicarboxyphenyl)phosphinic acid and zinc nitrate hexahydrate (ratio of substance amount is 10:1) to N,N'-dimethylformamide, ethanol and water (volume In a mixed solvent with a ratio of 1:1:1), the temperature was gradually raised to 85° C., reacted for 36 hours, cooled to room temperature, and filtered. Continuous soaking in acetone for 3 days, changing fresh acetone solution every 24 hours, and vacuum drying to obtain the zinc metal-organic framework material.

Embodiment 2

[0012] Example 2: Test of adsorption of methane gas by zinc metal-organic framework materials

[0013] On the specific surface and porosity analyzer, methane is passed into the adsorption cylinder containing 100mg of zinc metal-organic framework material at room temperature and normal pressure for adsorption test, and the adsorption capacity is 22.5cm 3 g -1 .

Embodiment 3

[0014] Example 3: Adsorption of propane by zinc metal-organic framework materials

[0015] On the specific surface and porosity analyzer, at room temperature and normal pressure, methane was passed into the adsorption cylinder containing 100 mg of zinc metal-organic framework material for adsorption test, and the adsorption capacity was 76 cm 3 g -1 According to the ideal adsorption solution theory (IAST) for equimolar two-component system, the selectivity coefficient of propane / methane is 285.1. Example 4: Test of adsorption of acetylene gas by zinc metal-organic framework materials

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com