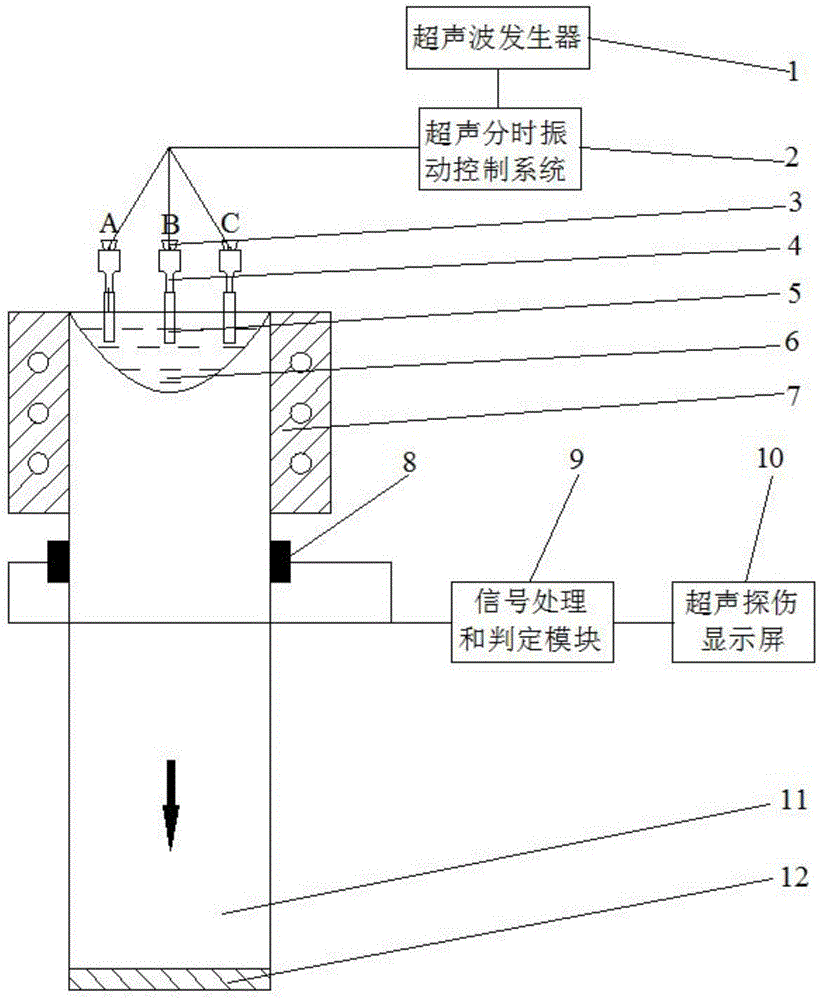

Magnesium alloy bar power ultrasonic semi-continuous casting and flaw detection device and method

A flaw detection device, magnesium alloy technology, applied in the direction of casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of combination, etc., to achieve the effect of smooth movement, low current and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] According to the ingredient ratio of AZ31B magnesium alloy, pure Mg, pure Al and pure Zn are melted and refined in an alloy melting furnace at 680-720°C in sequence, and then transferred to a holding furnace and kept at 720°C to ensure uniform temperature of alloy liquid , to be poured. Considering the phenomenon of shrinkage of 3-5mm and the removal of the defective layer with a thickness of 8-10mm on the outer skin of the cast rod, in order to produce a 90mm magnesium alloy cast rod, the diameter of the crystallizer is selected to be 105mm, according to the type of alloy, casting temperature and diameter of the cast rod and other parameters, select the ultrasonic field parameter as 100KHz pulse wave, the power as 1KW, and the matching casting speed as 100mm / min, and set the parameters on the power ultrasonic generator and semi-continuous casting machine respectively. Considering that the diameter of the casting rod pulled out from the crystallizer is about 100mm, six ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com