Bottom charging vacuum cleaning machine

A technology of vacuum cleaning machine and charging mechanism, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of insignificant separation of oil and water, residual cleaning, poor sealing performance, etc. The effect of complete drainage, no residue in drainage, and easy sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

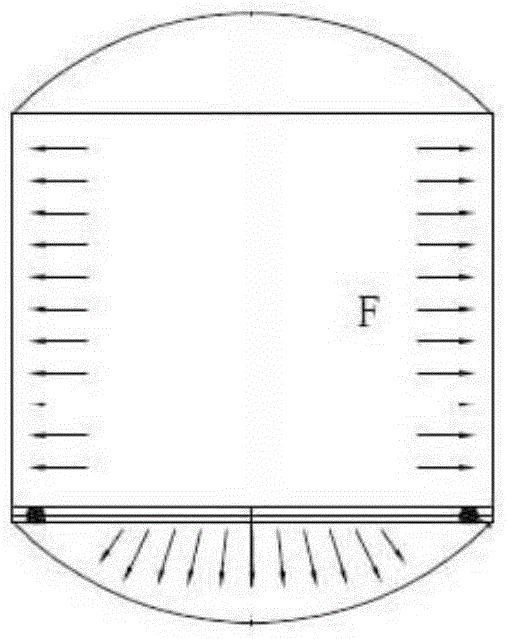

[0041] refer to Figures 1 to 10 , the present embodiment includes a body, and a lifting and charging mechanism S01, a cleaning chamber S02, an alkali solution storage tank S03, a clear water storage tank S04, a vacuum pump assembly S05, a spray assembly S06 and a water-gas separation device R01 arranged in the body , the cleaning room S02 has a cylindrical structure as a whole, and the top and bottom sealing doors 1 are in the shape of a semicircular convex surface; the inside of the cleaning room S02 is provided with a spray assembly S06, and the spray assembly S06 is composed of a water inlet pipe, a distribution pipe and a nozzle , the water inlet pipe runs through the top of the cleaning chamber S02, one end of the water inlet pipe is connected to two external pipes through the rotating head, and the other end extends into the interior of the cleaning chamber S02 and connects two right-angled distribution pipes through the distribution fittings, the two right-angled distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com