A kind of application method of biocomposite membrane material

A biocomposite membrane and application method technology, applied in the field of water purification, can solve the problems of complex preparation process, low adsorption capacity, secondary pollution, etc., and achieve the effects of stable physical and chemical properties, good film-forming performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

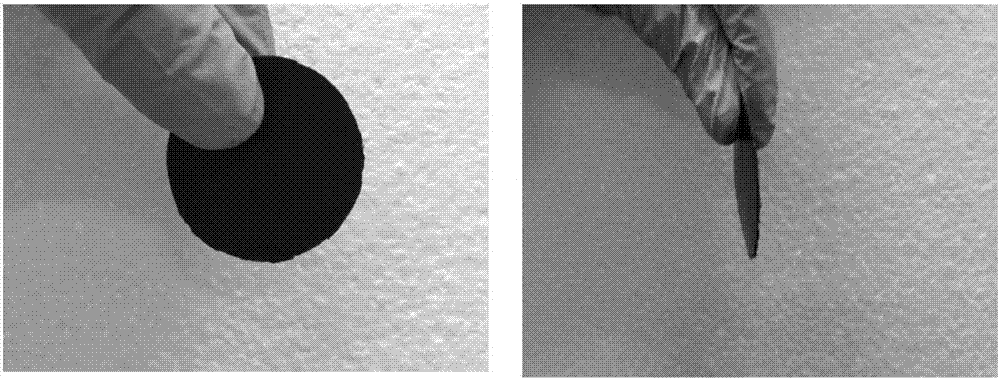

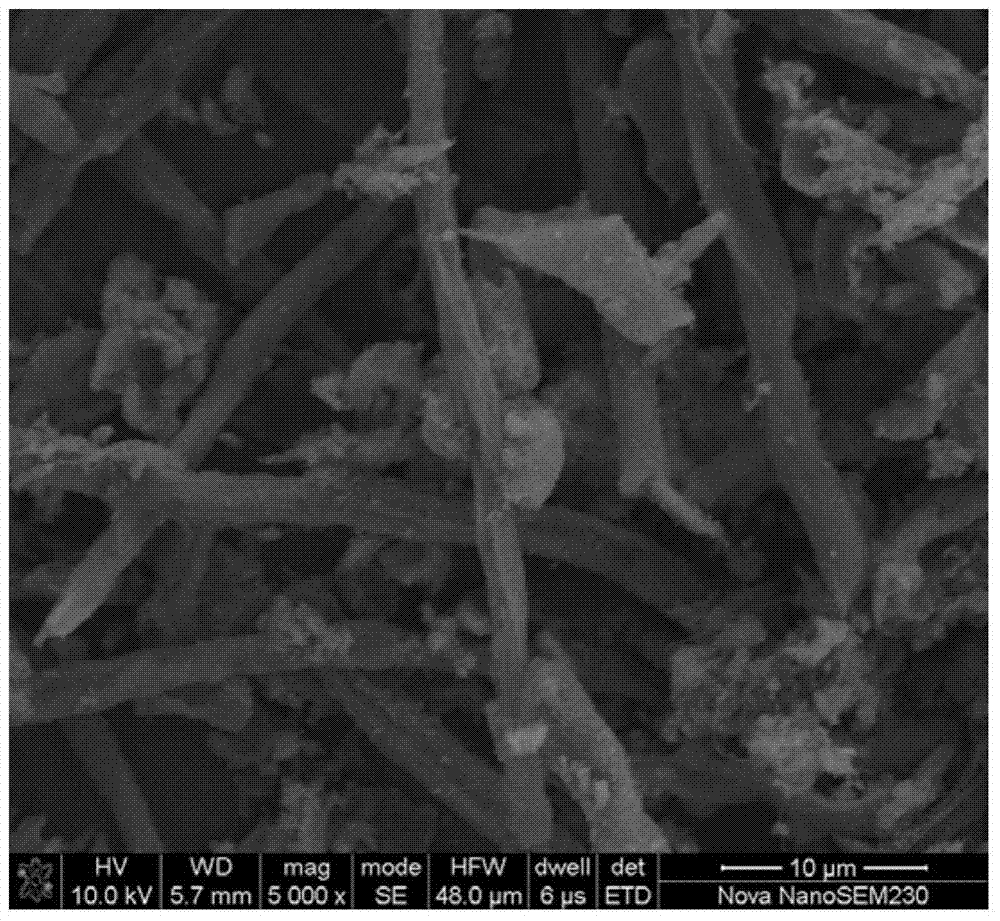

[0025] Prepare Cha's liquid culture medium, weigh 30g sucrose, 3g sodium nitrate, 1g dipotassium hydrogen phosphate, 0.5g magnesium sulfate heptahydrate, 0.5g potassium chloride and 0.01g ferrous sulfate, dissolve in 300mL deionized water, and then , the volume was adjusted to 1 liter with deionized water, and after high-temperature (121° C.) autoclaving for 30 minutes, a liquid medium was obtained for use. Inoculate the concentration 10 with the inoculation volume of 2% of the medium volume 6 -10 7 Aspergillus sp.F-1 (Aspergillus sp.F-1, preservation number CGMCC No.5858) bacteria solution per ml was inoculated into the liquid medium for culture, and then placed in a constant temperature shaking box with a temperature of 37°C and a rotation speed of 170r / min for 3 days; measure 100mL of bacterial solution (concentration is 9g L -1 ) into 150mL of 0.1mol / L ferric sulfate solution, add 0.1M NaOH dropwise to adjust the pH to 9.0, the reaction time is 72 hours, then heat the re...

Embodiment 2

[0027] At room temperature, the biofilm material prepared in Example 1 was used to filter the solution containing 1.52 mg / L of trivalent arsenic, and the concentration of trivalent arsenic in the filtered solution was measured by inductively coupled plasma atomic emission spectrometry. The concentration of arsenic after filtration was reduced to 0.13mg / L, and the removal efficiency of arsenic reached 91%.

Embodiment 3

[0029] At room temperature, the biofilm material prepared in Example 1 was used to filter the solution containing 40 mg / L trivalent arsenic, and the concentration of trivalent arsenic in the filtered solution was measured by inductively coupled plasma atomic emission spectrometry. The concentration of arsenic after filtration was reduced to 9.5mg / L, and the removal efficiency of arsenic reached 76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com