A probe in a scanning probe microscope, its preparation method and detection method

A scanning probe and detection method technology, applied in the probe field of scanning probe microscope, can solve problems such as inability to perform magneto-thermal, electro-thermal, obtaining single thermal information, and restricting in-depth understanding and research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0123] In this embodiment, the scanning probe microscope includes a scanning probe microscope platform, a probe, an electrical signal application unit, a displacement or vibration signal acquisition unit, a thermal signal acquisition unit, an electrical signal acquisition unit, and a central control unit. The probe control unit is used to drive or control the probe to move and / or vibrate. Central control unit: used to initialize each unit of the system, control each unit of the system, receive the shape, heat, and electrical signals of the sample, and obtain the shape, heat, and electrical signal images of the sample after analysis;

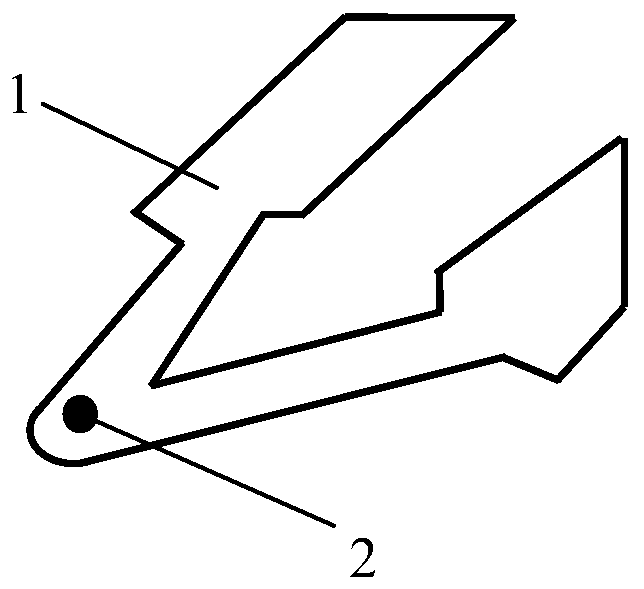

[0124] Such as figure 1As shown, the probe includes a probe arm 1 and a needle tip 2 .

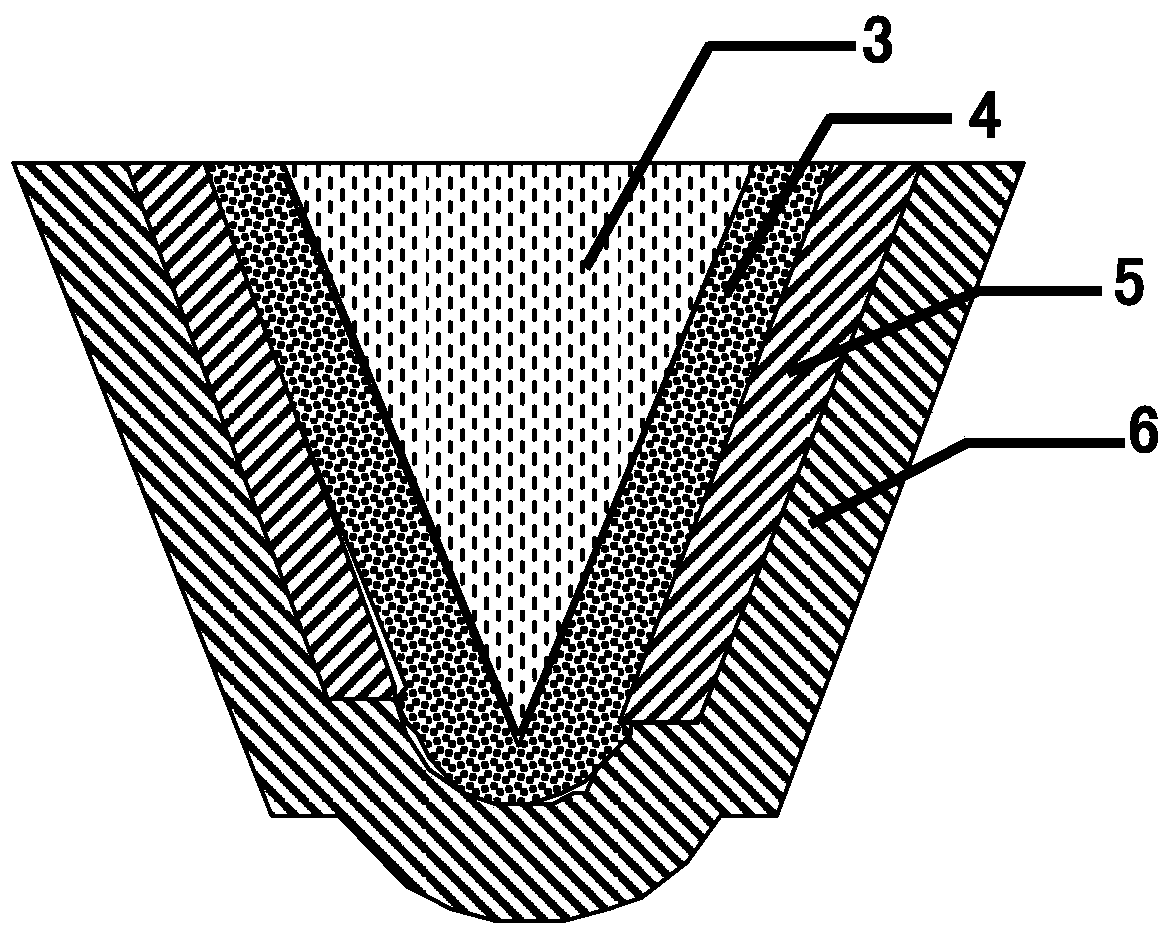

[0125] The structure of needle tip 2 is as follows figure 2 As shown, it is composed of the needle tip body 3 and the surface covering layer. The surface covering layer is composed of film one 4 , film one 4 covering the surface of film two 5 , and film tw...

Embodiment 2

[0149] In this embodiment, the structure of the scanning probe microscope is exactly the same as that in Embodiment 1.

[0150] The difference is that the probe tip with a thermocouple structure is prepared by another method, which includes the following steps:

[0151] Step 1. Using the coating method, film one 4, film two 5 and film three 6 are sequentially prepared on the surface of the needle tip body 3;

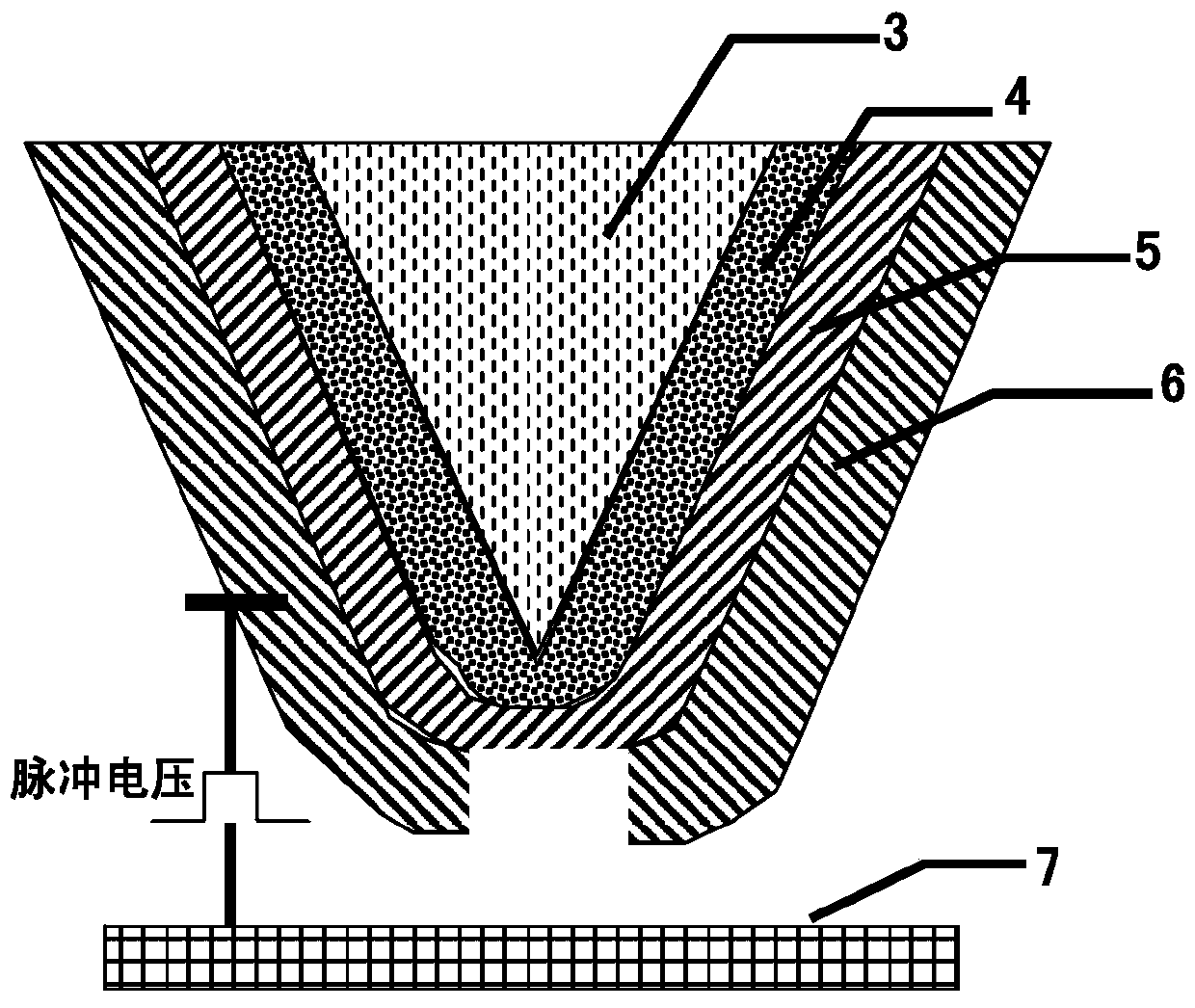

[0152] Step 2. Apply a voltage between the film 3 6 and the electrode layer 7, and use the tip discharge principle to adjust the distance between the film 3 6 and the electrode layer 7 to melt the film 3 6 at the tip of the needle point, exposing the film 2 5, and Other parts of the film 36 are not melted;

[0153] Step 3: remove the exposed film 2 5 described in step 2, and expose the film 1 4;

[0154] Step 4: Coating the exposed part with the same material as thin film three 6, so that thin film one 4 and thin film three 6 are connected at the tip of the needle tip ...

Embodiment 3

[0157] In this embodiment, the structure of the scanning probe microscope is basically the same as that in Embodiment 1, except that a probe with a thermal resistance structure is used.

[0158] Such as figure 1 As shown, the probe includes a probe arm 1 and a needle tip 2 . Tip 2 as Figure 4 As shown, it includes a needle point body 3, a thermal resistance material layer 8, a first conductive layer 9 and a second conductive layer 10; the thermal resistance material layer 8 is located on the surface of the needle point body 3, and the second conductive layer 10 is located on the surface of the thermal resistance material layer; A conductive layer 9 is in electrical communication with the thermal resistance material layer 8 .

[0159] The thermal resistance material layer 8 is made of low-doped silicon with a thickness of 2m, and the conductive layer 9 is made of bismuth (Bi), nickel (Ni), cobalt (Co), potassium (K), graphite, and graphene. , the thickness is 1 μm, the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com