A large-scale sampling machine for large-scale solid ore on the seabed

A large-scale, sampling machine technology, applied in the direction of sampling devices, etc., to achieve the effects of reducing pollution, improving transmission efficiency, and efficient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

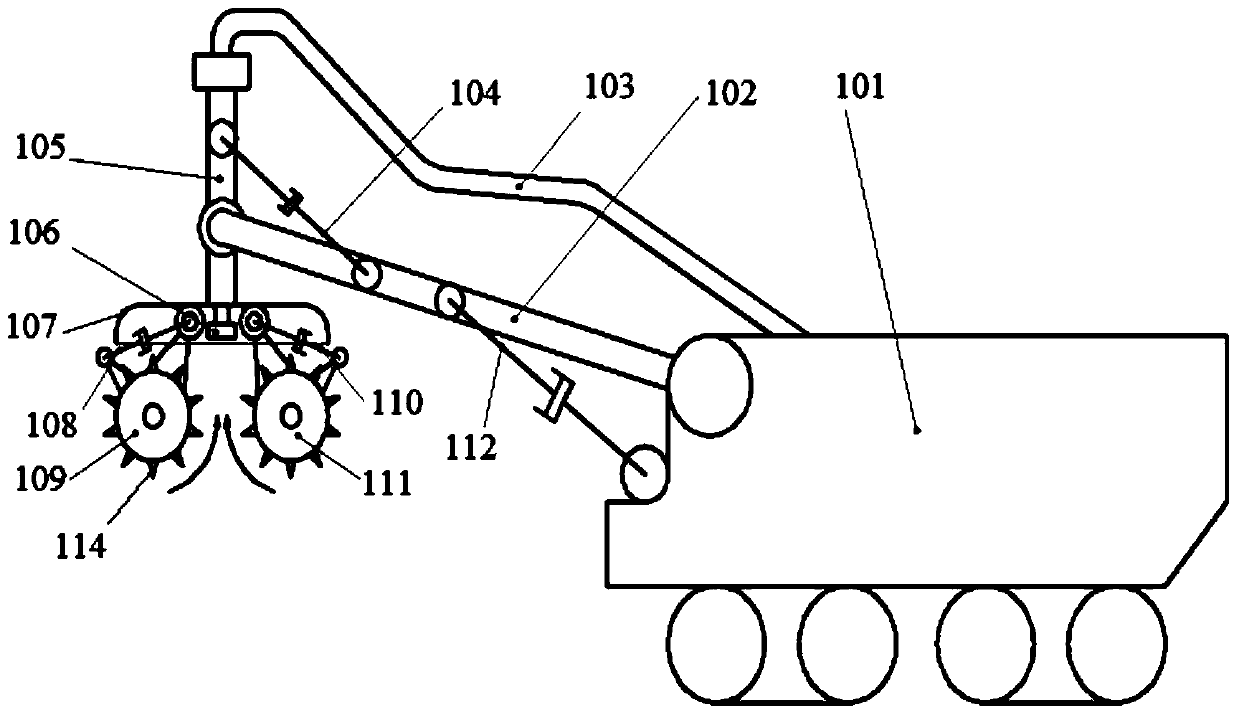

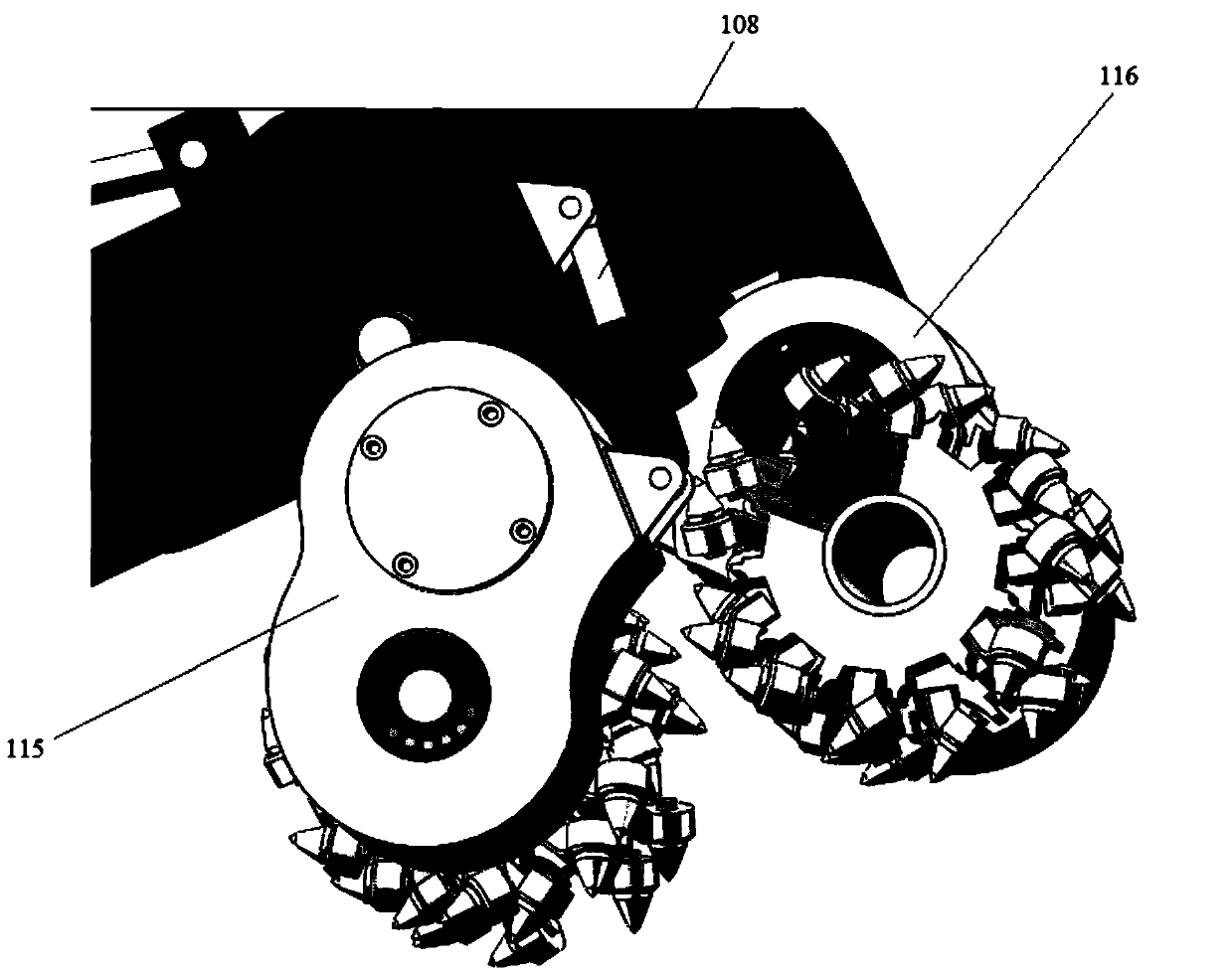

[0017] see figure 1 , the present embodiment comprises mine collecting car 101, big arm 102, hose 103, tilting device, small arm 105, slurry pump 106, collection cover 107, left cutting drum 109, right cutting drum 111 and height adjustment oil cylinder 112, large One end of the arm 102 is hinged on the mine collecting car 101, and the other end is hinged on the middle part of the small arm 105. One end of the height-adjusting cylinder 112 is hinged on the mine collecting car 101, and the other end is hinged on the boom to drive the boom to raise , the tilt adjustment device is installed on the boom and is connected to drive the small arm to produce a relative tilt with the vertical direction. The tilt adjustment device includes a tilt adjustment cylinder 104, one end of the tilt adjustment cylinder 104 is hinged on the boom, and the other end is hinged on the forearm to drive the forearm to tilt. The collection cover 107 is fixed on the bottom of the forearm. The left cuttin...

Embodiment 2

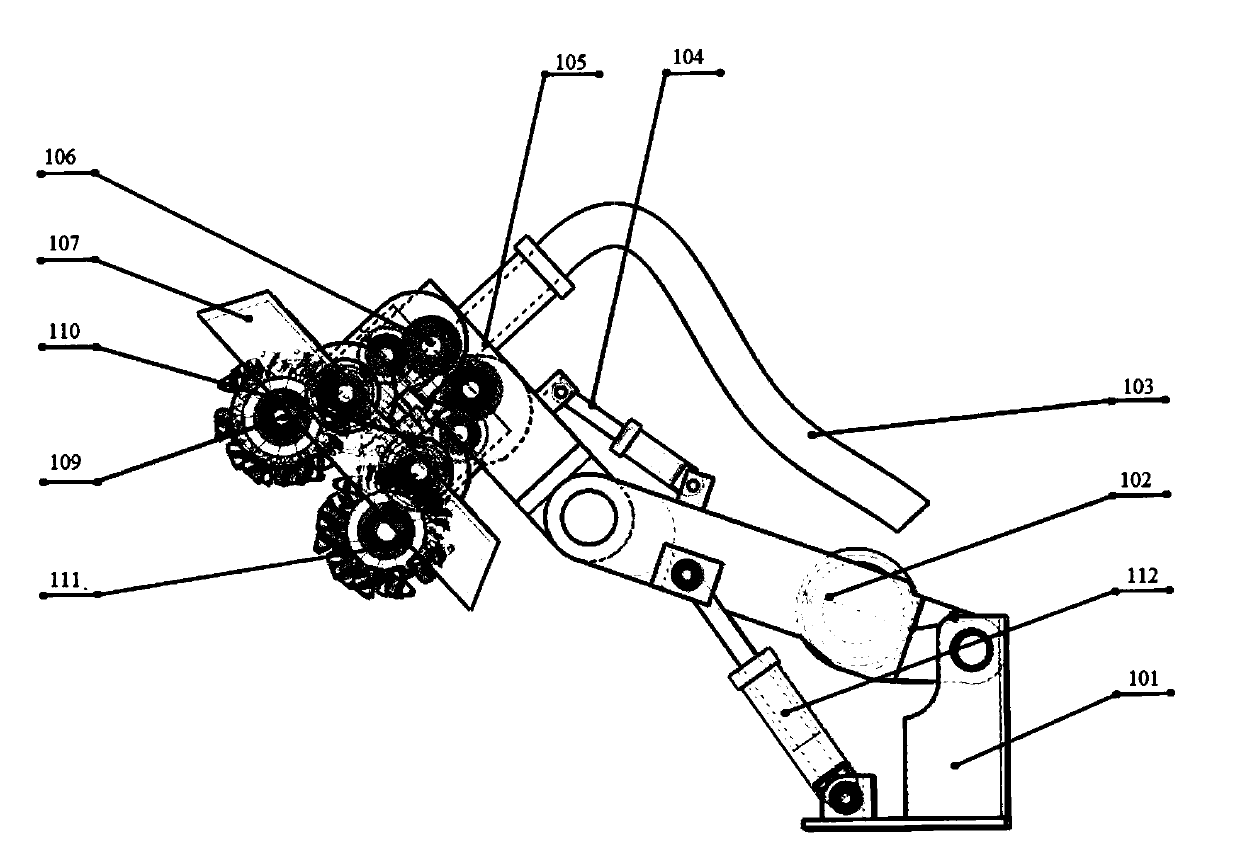

[0020] see figure 2 The difference between this embodiment and Embodiment 1 is that the tilting device includes a boom bending shaft 113 and a tilting cylinder 104, the boom bending shaft 113 is arranged in the middle of the boom, and one end of the tilting cylinder 104 is hinged One side of the shaft 113 and the other end are hinged on one side of the boom bending shaft 113 to drive the boom to bend to make the forearm tilt. In this way, through the bending of the boom, the adjustment of the inclination angle of the forearm can also be realized, so as to meet the sampling of ore with complex occurrence forms.

Embodiment 3

[0022] In order to satisfy the collection of ores in different distribution forms, on the basis of adopting the scheme of embodiment 1 or embodiment 2, this embodiment also includes a left rocker arm, a right rocker arm, a left fine-tuning oil cylinder and a right fine-tuning oil cylinder, a left cutting drum 109 and The right cutting drum 111 is respectively hinged to the forearm through the left rocker arm and the right rocker arm. One end of the left fine-tuning oil cylinder and the right fine-adjustment oil cylinder are hinged to the small arm, and the other ends are respectively hinged to the left rocker arm and the right rocker arm to drive the left rocker arm respectively. and the right rocker to adjust the angle and distance between the two roller cutting cylinders. The fine-tuning oil cylinders on the two rollers adjust the distance between the rollers in good time to meet the effective sampling of ore distributed in different fractions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com