Detachable compression dustbin

A technology of garbage bin and compression device, which is applied in the direction of garbage can, garbage collection, garbage cleaning, etc., can solve the problems of unfavorable environment improvement, poor efficiency, secondary environmental pollution, etc., so as to reduce the breeding of mosquitoes, improve the efficiency of collection and transportation, and avoid Effects of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment, technical solution of the present invention is described further in detail:

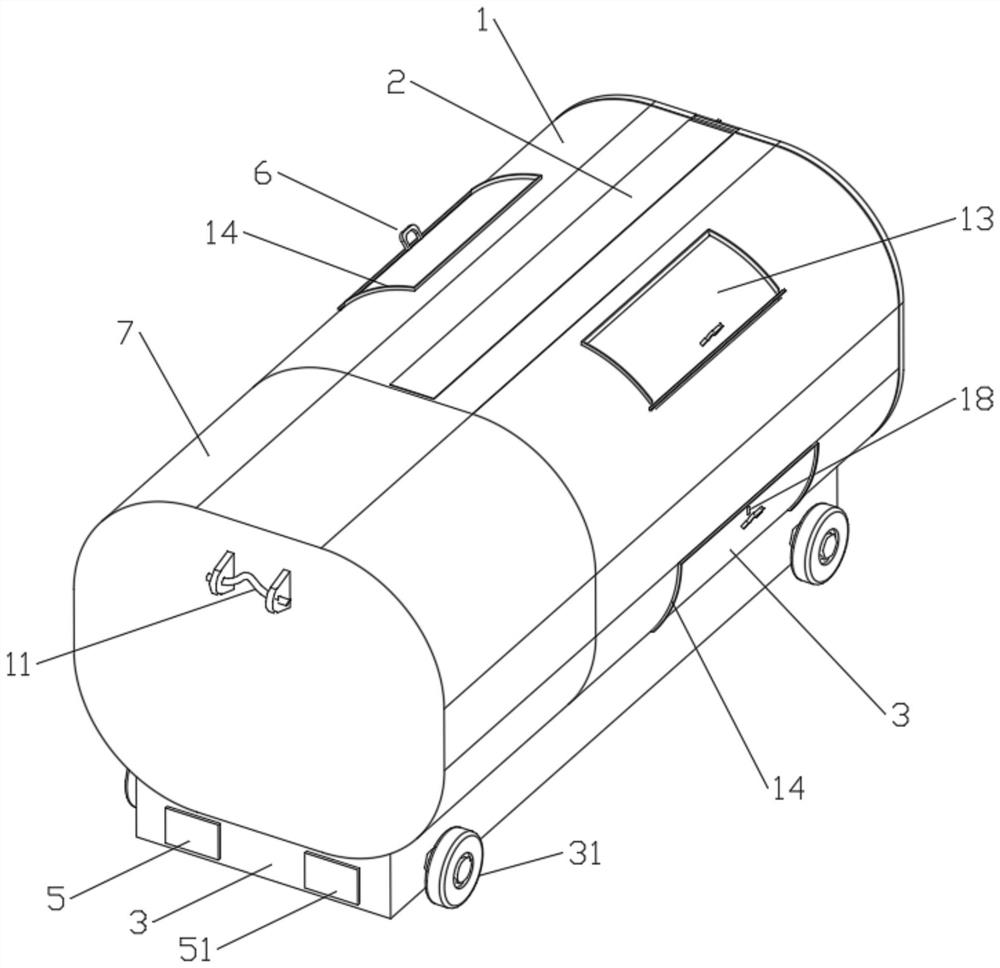

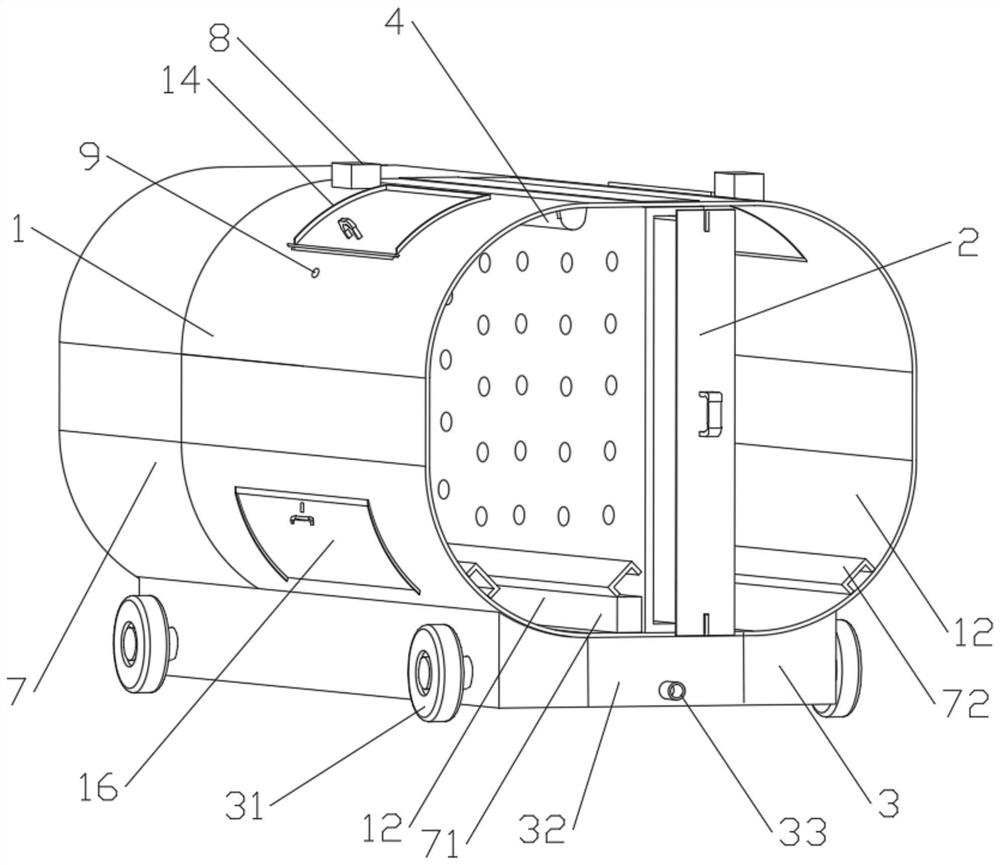

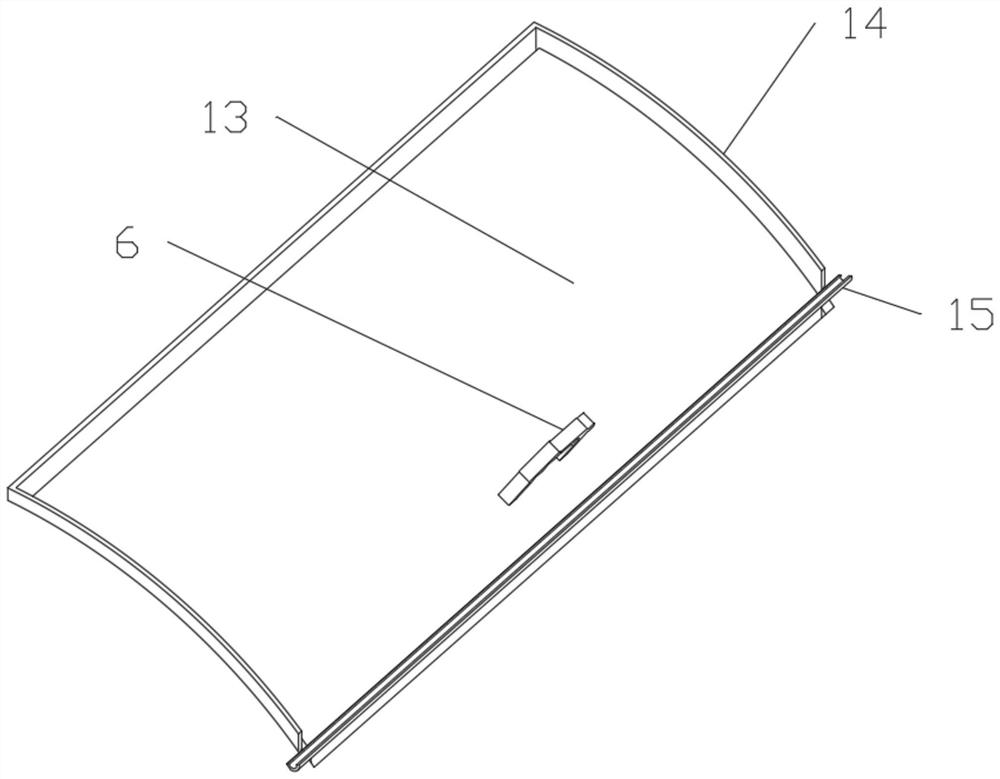

[0025] Please also refer to Figure 1-6 , the detachable compressed garbage bin provided in this embodiment includes a garbage bin body 1 provided with a hook 11, and a deodorizing device 2 and a compressing device 7 are arranged inside the garbage bin body 1, and the deodorizing device 2 will The garbage bin body 1 is divided into two sorting collection boxes 12 respectively, and each of the sorting collection boxes 12 is provided with a feeding port and a discharge port, and the feeding port is located at the top of the garbage bin body 1 and is provided with a feeding door 13 , the three sides of the feeding port and the discharge port are provided with a water retaining plate 14, and the feeding door 13 is provided with a rainwater guide groove 15, and the rainwater guiding groove 15 stretches out from two ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com