Intelligent garbage container

A container and garbage technology, applied in the direction of garbage collection, trash cans, household appliances, etc., can solve the problems of inability to effectively monitor the state of garbage in the garbage can, potential safety hazards, etc., to prevent safety accidents, eliminate safety accidents, and have a high degree of intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

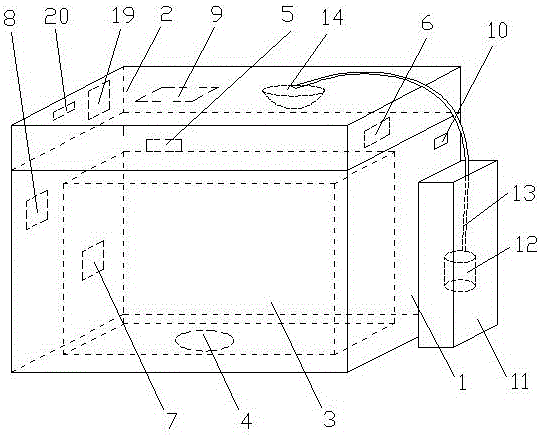

[0029] See figure 1 , An intelligent garbage container, including a box body 1, a box cover 2 and an inner tube 3 arranged in the box body 1. A weight sensor 4 is installed between the bottom surface of the inner tube 3 and the bottom surface of the box body 1, and the inner tube 3 Placed on the weight sensor 4, a volume sensor 5 is fixed on the inner wall of the box body 1, and the volume sensor 5 is located at the edge of the opening of the inner cylinder 3. The inner side wall of the box cover 2 is connected with a single-chip microcomputer 6. The weight sensor 4 and the volume sensor 5 are respectively electrically connected to the single chip microcomputer 6, a temperature sensor 7 is connected to the inner wall of the inner cylinder 3, a smoke sensor 8 is connected to the inner wall of the box body 1, and the box cover 2 A wireless transmitter 9 is connected to the inner top wall. The temperature sensor 7, the smoke sensor 8 and the wireless transmitter 9 are electrically ...

Embodiment 2

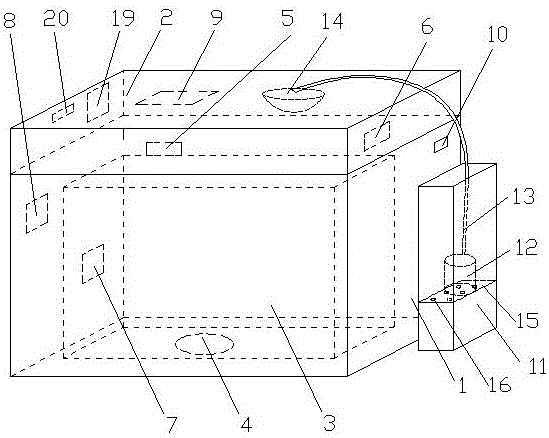

[0032] See figure 2 , An intelligent garbage container, including a box body 1, a box cover 2 and an inner tube 3 arranged in the box body 1. A weight sensor 4 is installed between the bottom surface of the inner tube 3 and the bottom surface of the box body 1, and the inner tube 3 Placed on the weight sensor 4, a volume sensor 5 is fixed on the inner wall of the box body 1, and the volume sensor 5 is located at the edge of the opening of the inner cylinder 3. The inner side wall of the box cover 2 is connected with a single-chip microcomputer 6. The weight sensor 4 and the volume sensor 5 are respectively electrically connected to the single chip microcomputer 6, a temperature sensor 7 is connected to the inner wall of the inner cylinder 3, a smoke sensor 8 is connected to the inner wall of the box body 1, and the box cover 2 A wireless transmitter 9 is connected to the inner top wall. The temperature sensor 7, the smoke sensor 8 and the wireless transmitter 9 are electrically...

Embodiment 3

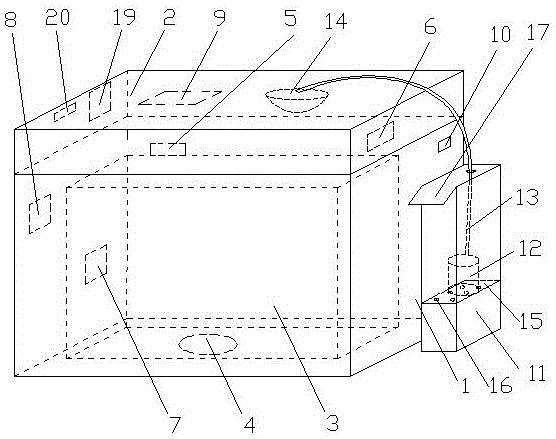

[0036] See image 3 , An intelligent garbage container, including a box body 1, a box cover 2 and an inner tube 3 arranged in the box body 1. A weight sensor 4 is installed between the bottom surface of the inner tube 3 and the bottom surface of the box body 1, and the inner tube 3 Placed on the weight sensor 4, a volume sensor 5 is fixed on the inner wall of the box body 1, and the volume sensor 5 is located at the edge of the opening of the inner cylinder 3. The inner side wall of the box cover 2 is connected with a single-chip microcomputer 6. The weight sensor 4 and the volume sensor 5 are respectively electrically connected to the single chip microcomputer 6, a temperature sensor 7 is connected to the inner wall of the inner cylinder 3, a smoke sensor 8 is connected to the inner wall of the box body 1, and the box cover 2 A wireless transmitter 9 is connected to the inner top wall. The temperature sensor 7, the smoke sensor 8 and the wireless transmitter 9 are electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com