A fast wellhead docking device and its application method

A docking device and fast technology, applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as inconvenience, low efficiency, and insufficient safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

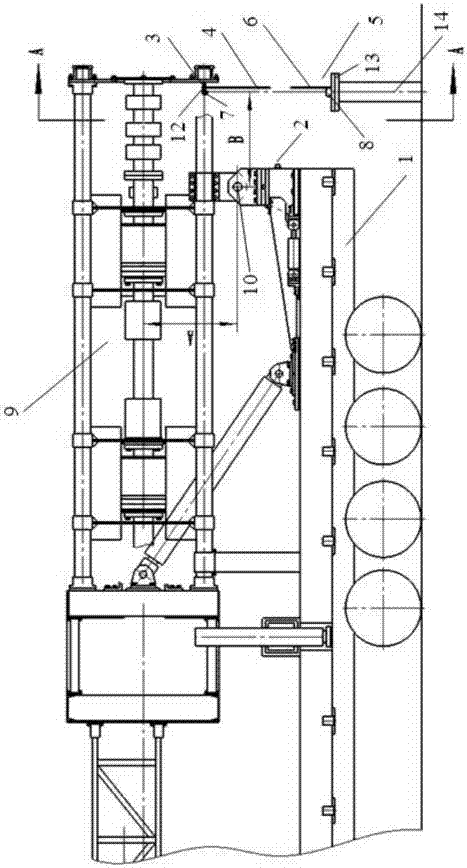

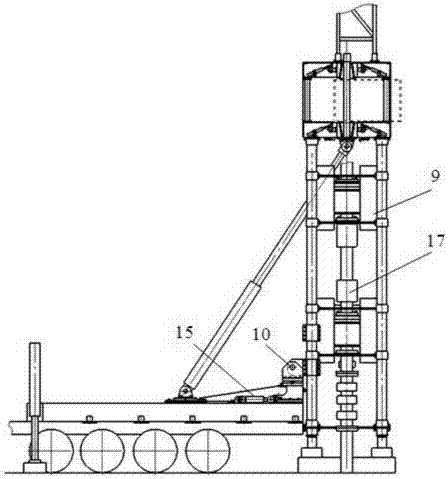

[0014] See attached figure 1 , camera 2 is installed in the center of the tail of the car body system 1 (i.e. the centerline of the derrick system 9), and the tail image during its reversing can be transmitted to the display screen in the cab. According to the pointer 4 on the derrick alignment device 3 and the pointer 6 on the wellhead alignment device 5 seen on the display screen, the driver aligns the vehicle body system 1 (that is, the centerline of the derrick system 9 ) and the wellhead center 14 at the width of the vehicle body. Alignment in direction.

[0015] Keep the correct direction and continue to reverse slowly. When the cross cursor in the camera 7 on the derrick alignment device 3 is aligned with the cross mark on the reflection seat 8 on the center of the wellhead alignment device 5, the car body system 1 (that is, the derrick) is ensured. The center line of system 9) is aligned with the wellhead center 14 in the car body length direction, and this process ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com