White bamboo charcoal fiber blended knitted fabrics and manufacturing method thereof

A fiber blended and knitted fabric technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve the problem of inability to complete bleaching and coloring of white and light-colored fabrics, and achieve enhanced moisture absorption and quick-drying performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to specific embodiments, but the protection scope of the present invention is not limited.

[0016] A white bamboo charcoal fiber blended knitted fabric, the fabric yarn adopts 14.5tex white bamboo charcoal fiber and cotton blended yarn, the blending ratio is 45:55, and 150D / 144f Coolmax yarn is woven together, and the lower machine width of the fabric is completed. is 95cm.

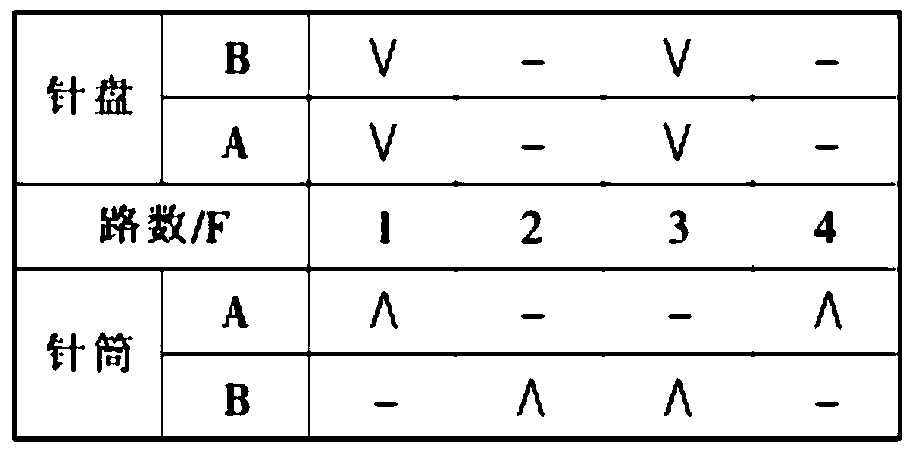

[0017] A manufacturing method of a white bamboo charcoal fiber blended knitted fabric, the fabric is woven with a 30-inch, 18-needle rib machine, and the white bamboo charcoal fiber and cotton blended yarn is inserted into the odd number of channels, and the Coolmax yarn is inserted into the even number of channels, Rib alignment is adopted, the dial needle is one type of needle knitting, and the cylinder needle is alternately arranged in AB.

[0018] The triangular arrangement is shown in the following table:

[0019]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com