Method for raising refractive index of hafnium oxide film

A technology of refractive index and film layer, which is applied in the field of electron beam evaporation coating, can solve the problems affecting the anti-laser damage threshold of thin-film components, and achieve the effect of improving the anti-laser damage threshold, increasing the band gap of the film layer, and increasing the refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in conjunction with embodiment and accompanying drawing below.

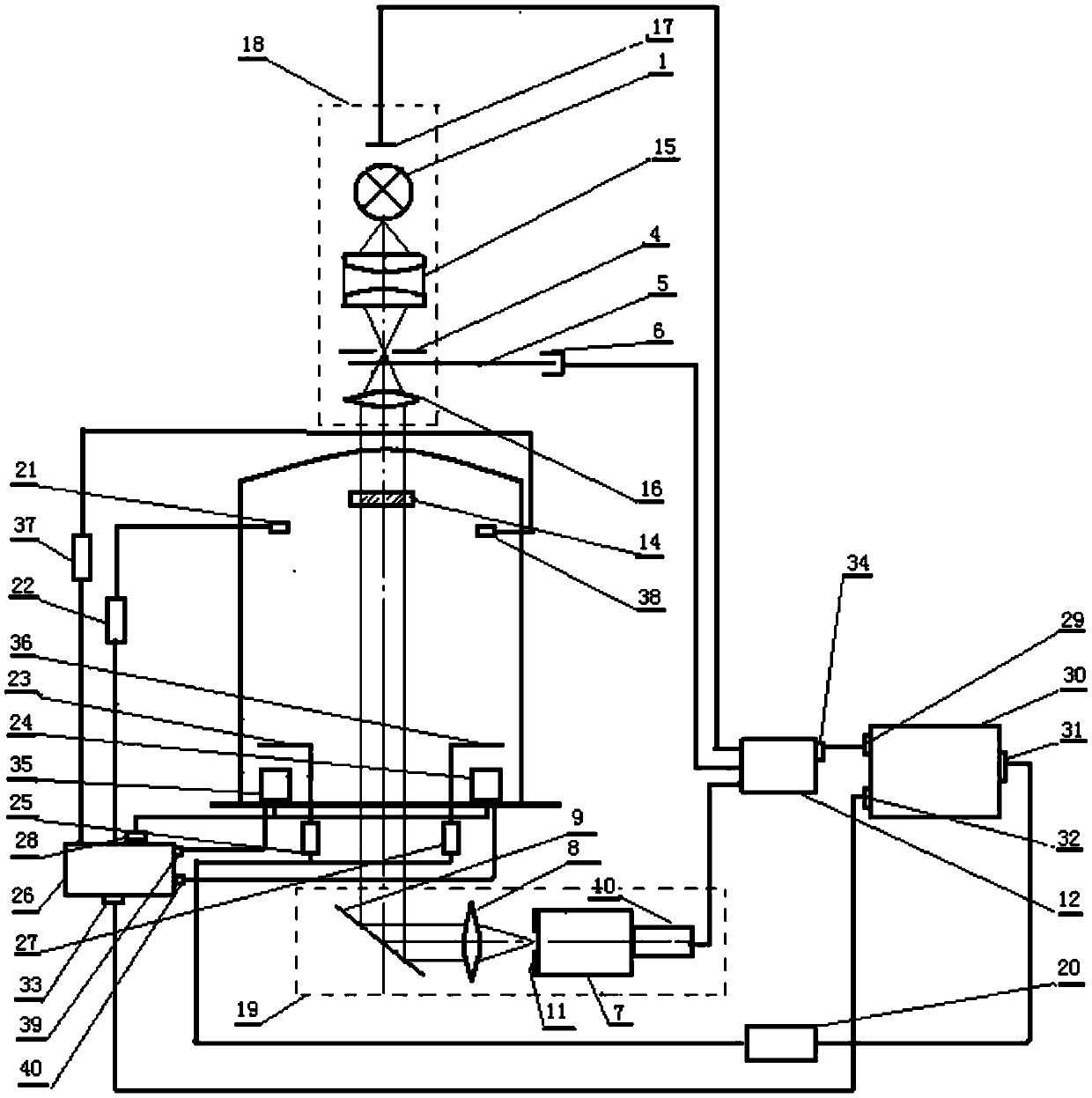

[0022] see first figure 1 , figure 1 Improve HfO for the present invention 2 Schematic diagram of the structure of the computer-controlled electron beam evaporation coating machine coating device used in the method of film layer refractive index. As can be seen from the figure, the coating device used in the present invention includes an optical film thickness monitoring system composed of light source emission system 18, monitoring sheet system 14, signal receiving system 19 and lock-in amplifier 12, and a computer 30 with control program , The baffle switch control circuit 20. The lock-in amplifier 12 is connected to the first serial port 29 of the computer 30 with the control program through the RS232 serial port 34 that comes with it, and the 2nd pin and the 3rd pin of the computer parallel port 31 pass through the shielded wire through the baffle swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com